In today’s building industry, placing expanded polystyrene (EPS) beneath concrete slabs has turned into a common approach. Recognized for its great ability to insulate and provide solid support, EPS is becoming a top pick for homes and businesses alike. So, why do people use Styrofoam—also known as EPS—under concrete? This piece dives into the reasons, perks, traits, uses, and setup methods of EPS under concrete. It also highlights the top-notch options provided by HUASHENG.

The Purpose of Using EPS Material Beneath Concrete

EPS plays several roles when placed under concrete slabs. It does more than just insulate. It boosts the structure’s strength and helps it last longer.

Thermal Insulation Benefits in Construction Applications

EPS works as a strong shield against heat between the soil and the concrete slab. These materials have amazing heat-blocking skills. They cut down on energy use in buildings. By stopping heat from moving from the ground to inside spaces, EPS keeps indoor temperatures steady all year. This saves money on heating and cooling. Plus, it supports eco-friendly building habits.

Moisture Resistance and Long-Term Durability

Moisture sneaking in is a big problem under slabs. EPS has a closed-cell design. This means it doesn’t soak up water. It stays the same size even when it’s damp. This feature helps it keep insulating well over many years without breaking down.

Load Distribution and Structural Support Enhancement

Even though EPS is light, it can handle heavy pressure. When put under concrete slabs, it spreads the weight evenly across the base. This lowers stress on the dirt underneath. It works well for small home projects and big business or factory floors too.

Key Properties of Expanded Polystyrene (EPS)

The benefits of EPS come from its special physical and chemical features.

Low Thermal Conductivity and Energy Efficiency

EPS has a low heat transfer rate, usually between 0.030 to 0.040 W/m·K. This makes it a fantastic insulator. It acts as a steady barrier against heat. As a result, it helps keep indoor spaces comfy no matter the season.

Lightweight Nature and Ease of Installation

EPS weighs a lot less than old-school options like gravel or stiff foam boards. This makes it easier to move and set up. Workers can cut the panels to the right size right on the job site. They don’t need big machines for this task.

Resistance to Water Absorption and Freeze-Thaw Cycles

Thanks to its closed-cell build, EPS takes in very little water—less than 2% by volume. It holds up well even in areas that freeze and thaw often. This makes it a great choice for outdoor spots or places below ground where water might be an issue.

Applications of EPS in Concrete Construction

EPS is super flexible. It’s used in many different building areas.

Residential Building Foundations and Slab-on-Grade Floors

In houses with slab-on-grade setups, EPS insulates under the slab. It stops cold from creeping up from the ground. This makes living spaces feel warmer and more cozy.

Commercial and Industrial Flooring Systems

Places like warehouses, factories, and stores gain from EPS’s ability to bear weight under thick concrete layers. Its insulating power also helps control temperatures in big, open spaces.

Infrastructure Projects: Roads, Bridges, and Embankments

EPS blocks are used as filler in road building because they’re light yet tough. They lessen sinking on soft ground. They also reduce the weight on lower layers. This is really important for bridge supports and embankments.

Types of EPS Grades Used Under Concrete

HUASHENG provides a broad selection of EPS grades made for specific building needs.

Common Grade for General Insulation Needs

HUASHENG EPS foam items, like EPS panels and EPS foam sheets, fit many uses. The Common grade works well for basic under-slab insulation. It’s perfect when extra fire safety or top heat-blocking isn’t needed.

Flame Retardant Grade for Enhanced Fire Safety

For projects needing strict fire rules, like underground parking or busy buildings, HUASHENG offers B1 Flame Retardant Grade EPS particles with a density of 22kg/m³. This is a great fit for safety-focused jobs.

Graphite Grade for Superior Thermal Performance

Graphite-modified EPS has carbon bits that bounce back heat rays. HUASHENG’s lineup includes regular, flame-retardant, and graphite-modified types. These offer up to 20% better heat resistance than plain white EPS.

Environmental Protection Grade for Sustainable Building Practices

HUASHENG recycles 300,000 tons of EPS each year. This saves 1,500,000 tons of crude oil and 1,200,000 tons of carbon dioxide. Their Environmental Protection Grade meets green building rules like LEED. It uses recycled stuff without losing quality.

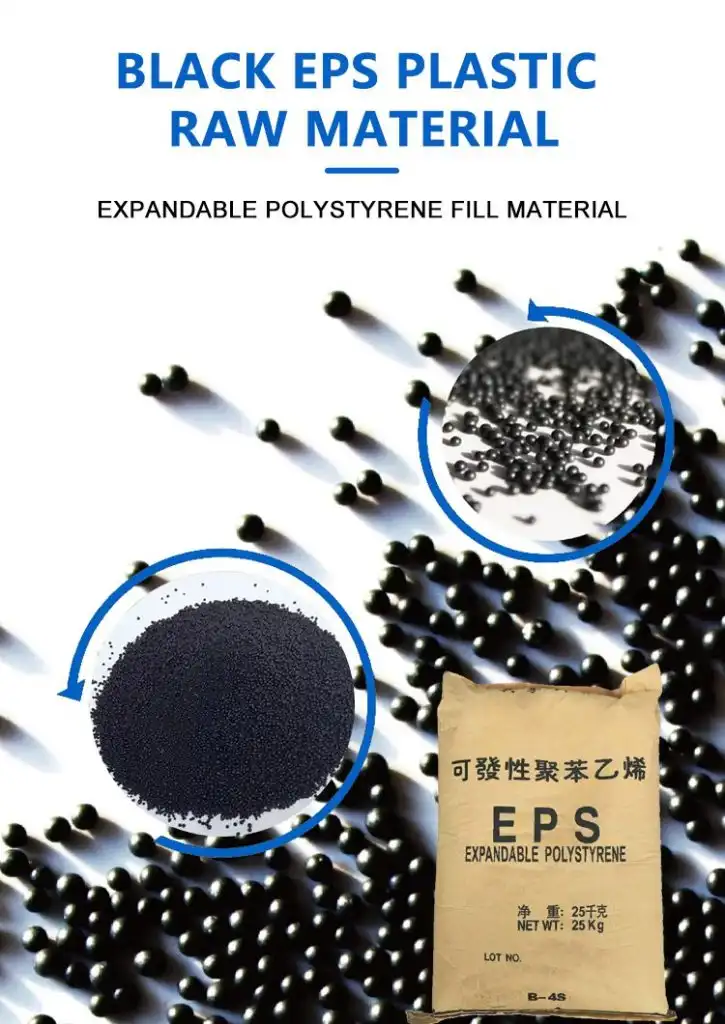

Carbon Black Grade for UV Resistance and Strengthening

Carbon Black Grade EPS boosts protection against UV rays when stored outside before the slab is poured. It also adds extra toughness against wear during setup.

Customized REPS Solutions Tailored to Project Requirements

HUASHENG thrives on creativity and new tech. Their Customized REPS line offers made-to-order options. Think colored bits or specific weights for unique designs. This works for everything from art pieces to green city plans.

EPS vs. Traditional Insulation Materials Under Concrete

Picking the right insulation means looking at more than just the price tag.

Comparison with Rigid Foam Boards (XPS, Polyiso)

XPS might soak up a tiny bit less water than regular white EPS. But it costs more and gives similar warmth per inch. Polyiso doesn’t do well in cold weather compared to graphite-boosted or high-density EPS choices.

Cost-Effectiveness Over Time

EPS often costs less at the start than XPS or Polyiso. Yet, it performs just as well over the years if set up right under concrete slabs.

Environmental Impact and Recyclability

HUASHENG mixes green thinking with new ideas. They focus on recycling. Their closed-loop making process cuts waste to almost nothing. It also supports reusing materials for a better, circular economy.

Installation Techniques for EPS Under Concrete Slabs

Setting up EPS the right way is key to getting the most out of it under concrete slabs.

Site Preparation and Base Layer Considerations

First, make a flat, packed-down base, often with gravel. Then, lay down a vapor shield before placing EPS panels. A smooth surface stops gaps. Gaps can cause heat leaks or make the slab wobbly over time.

Proper Placement, Spacing, and Layering of EPS Panels

Fit the panels close together. If using more than one layer, stagger the seams. This adds strength. Fill any small gaps with spray foam or tape them shut, based on the project’s needs.

Integration with Vapor Barriers and Reinforcement Meshes

Vapor shields block dampness from moving up from the ground into the concrete. Reinforcement meshes add strength on top of insulated layers. This is super important for heavy-use spots like driveways or factory floors.

Potential Challenges and How to Address Them

Even with all its pluses, using Styrofoam under concrete has some things to watch out for during planning.

Compression Under Heavy Loads

High-density EPS grades are strong, with over 100 kPa of compressive power. Still, builders must pick the right thickness for expected weights. This avoids bending or breaking over time, especially under heavy spots like pillars or machine bases.

Compatibility with Different Soil Types

Soft, mushy soils like clay might need extra firming up before using light fillers like EPS blocks. It’s smart to check the ground with a soil expert before starting in tricky areas.

Ensuring Proper Drainage Around the Slab

Water pressure under slabs can mess up insulation and strength. To stop this, set up good drainage systems around the edges. Pair this with vapor shields under the slab to keep things dry and steady.

Introduction to HUASHENG as a Reliable EPS Supplier

As the need for green building answers grows worldwide, HUASHENG steps up. They offer EPS foam products for concrete floors and bases. Their range goes from simple panels to complex systems that meet tough global rules.

Since starting, HUASHENG New Materials has built a smart, modern production setup. This ensures their goods lead in things like even density and strong pressure handling.

Their promise goes beyond just making stuff. They care for the planet with cool recycling methods. They use advanced compacting systems that shrink volume by 50:1. Plus, their solvent-based recycling makes EPS as good as new.

Whether you need basic panels or Customized REPS solutions for special building ideas, HUASHENG has you covered. Find the perfect high-quality EPS panel or EPS foam sheet for your job today!

FAQs:

Q1: Why do builders put Styrofoam under concrete slabs?

A: Builders use Styrofoam, or EPS, under concrete mainly to block heat loss through floors. It also spreads weight evenly and fights off water damage over the years. These items are awesome at keeping indoor spaces cozy no matter the weather outside.

Q2: Is expanded polystyrene environmentally friendly?

A: Yes, it is! HUASHENG recycles 300,000 tons of EPS every year. This saves 1.5 million tons of crude oil. Their green ways help reuse materials and cut down harm to the earth throughout the product’s life.

Q3: Can I use regular Styrofoam instead of construction-grade EPS?

A: No, it’s not a good idea. Construction-grade EPS is made with exact density and strength levels for building jobs. HUASHENG ensures top standards in things like even density. Regular packing foam doesn’t have what it takes to hold up under heavy concrete slabs.