The production of EPS foam depends on polystyrene as its base material which serves multiple industries including construction and packaging and insulation applications. The knowledge of polystyrene origins helps EPS foam manufacturers to develop better supply chain methods while maintaining product quality and environmental compliance. This paper examines the source of polystyrene and its conversion into EPS foam while analyzing supply chain operations and the innovative approaches of major suppliers including HUASHENG.

The Origin of Polystyrene as a Raw Material

The production of polystyrene begins with hydrocarbon extraction which leads to multiple chemical transformations until it reaches its final form as EPS foam.

Petrochemical Derivatives and the Role of Crude Oil

Polystyrene is a synthetic aromatic hydrocarbon polymer made from the monomer styrene. Styrene itself is derived from benzene and ethylene—two petrochemical derivatives that are extracted during crude oil refining. This makes crude oil the fundamental raw material source for polystyrene production.

The Process of Extracting Styrene Monomer

Styrene production starts with ethylbenzene dehydrogenation followed by ethylene reaction with benzene to produce ethylbenzene. The production of styrene monomer requires elevated temperatures and catalysts to create this colorless liquid which functions as the base material for polystyrene production.

Global Sources and Major Exporting Countries

Styrene monomer production occurs mainly in countries with strong petrochemical sectors including China and the United States and South Korea and Germany and Saudi Arabia. The nations with strong petrochemical industries export their raw materials to EPS foam manufacturers throughout the world through direct shipments and international distribution channels.

Industrial Production of Expandable Polystyrene (EPS)

The styrene monomers need to go through polymerization to create solid polystyrene beads that will become EPS foam after expansion.

Polymerization Techniques in EPS Manufacturing

The production of EPS polystyrene beads occurs through suspension polymerization methods. The styrene monomers undergo polymerization in water solution with initiators and stabilizers to create the beads. The beads receive their blowing agent content through an impregnation process with pentane.

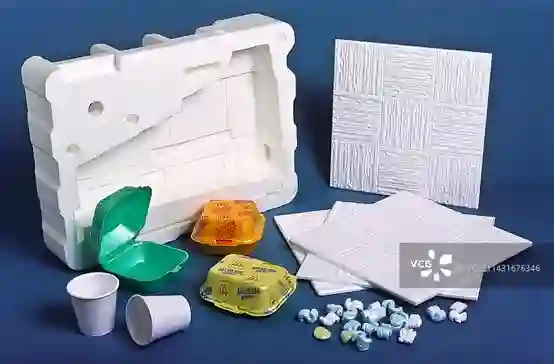

EPS (Expandable Polystyrene) functions as an insulation material which maintains its lightweight structure while being rigid and originates from solid polystyrene particles.

Key Additives and Their Functional Roles

Manufacturing performance characteristics receive improvement through the addition of additives to EPS formulations.

Blowing Agents for Expansion

The production process involves dissolving small amounts of pentane gas into polystyrene base material to achieve expansion. The gas inside each bead expands through steam heat processing which creates closed-cell structures that result in a 40 times larger volume than the original size.

Flame Retardants and Stabilizers

The addition of flame retardants enhances fire resistance but stabilizers protect the material structure during molding operations. The additives help organizations meet safety standards which apply to different market segments.

Supply Chain Dynamics for EPS Foam Manufacturers

The production of EPS requires efficient sourcing methods to achieve both cost efficiency and reliable raw material quality.

Sourcing Strategies for Raw Polystyrene

EPS foam manufacturers operate under two main sourcing systems which they use based on their production scale and geographical location.

Direct Procurement from Petrochemical Plants

Large-scale manufacturers create direct connections with petrochemical refineries and polymer producers to purchase bulk materials at affordable prices. The method provides quality control but needs substantial logistical management to implement.

Use of Distributors and Trading Companies

The supply chain of smaller manufacturers who operate within specific regions depends on trading companies and distributors who collect products from various suppliers. The model gives flexibility to the system but it creates price and delivery time inconsistencies.

Price Volatility and Its Impact on Procurement Decisions

Polystyrene prices experience market fluctuations because this product originates from petroleum resources which are influenced by worldwide crude oil market changes. The petroleum industry faces price instability because of political conflicts and refinery shutdowns and shifting market requirements which leads manufacturers to use risk management techniques through hedging and supplier diversification.

Environmental Considerations in Sourcing Polystyrene

The growing demand for industrial carbon emission reduction has made environmentally friendly sourcing a critical requirement for EPS manufacturers.

The Push Toward Sustainable Sourcing Practices

Leading organizations today focus on green production techniques which reduce environmental emissions and minimize waste throughout their manufacturing operations. The selection of suppliers who follow ISO-certified environmental standards is part of sustainable sourcing practices.

Recycled Polystyrene as an Alternative Feedstock

The company provides two types of lightweight energy-efficient products made from recycled EPS foam and EPS foam beads. The use of recycled materials helps decrease virgin petrochemical usage while supporting circular economy principles through waste-to-product recycling.

Regulations Affecting Raw Material Selection

The selection of raw materials for construction materials such as EPS foam is now influenced by environmental regulations that include REACH (EU) and EPA guidelines (USA) and China’s Green Product Certification system because these regulations require lower emissions and recyclable materials.

Quality Standards and Certifications in Raw Polystyrene Materials

The implementation of global standards enables raw materials to fulfill particular requirements which different industries need for their applications such as construction and food packaging.

Industry Benchmarks for EPS Foam Applications

The selection of EPS for thermal insulation requires evaluation based on compressive strength and dimensional stability and water absorption rate and thermal conductivity which differ according to application requirements between wall insulation and packaging.

EPS Material Properties: Density: Low density Thermal Insulation: Excellent thermal insulation properties Shock Absorption: High shock-absorbing capability Versatility: Can be molded into various shapes.

Compliance with International Safety and Environmental Guidelines

The use of certifications like ISO 9001 (quality management) and ISO 14001 (environmental management) and CE marking (Europe) and UL certification (USA) and RoHS compliance guarantees that raw materials meet the safety standards which regulatory bodies across the world have established.

Regional Differences in Raw Material Availability

The availability of raw materials depends heavily on geographic location because infrastructure and regulatory frameworks and market development levels vary between locations.

Asia-Pacific: Leading Producers and Suppliers

China leads the world in production because it operates a massive petrochemical complex with complete supply chain integration. The local supply of materials enables regional manufacturers to decrease their transportation expenses while they can expand their operations quickly through partnerships within the country.

Europe: Regulatory Constraints and Market Adjustments

European producers must follow strict environmental rules that promote recycled content usage but these regulations restrict their ability to obtain virgin materials freely which drives some companies to import Asian materials through eco-compliance programs.

North America: Domestic Production vs. Imports

The United States operates a powerful domestic petrochemical industry yet it imports from Latin America and Asia-Pacific markets when domestic supply falls short or when policy changes occur during specific periods of high demand in construction and packaging industries.

Technological Innovations in Raw Material Processing

The scientific progress enables better methods to convert raw polystyrenes into specialized high-performance EPS foams which serve contemporary needs.

Advances in Polymer Chemistry for EPS Applications

The new copolymer blends provide improved impact resistance and lower density without affecting insulation performance which makes them suitable for automotive parts and seismic packaging applications that require maximum weight reduction.

Role of Automation in Enhancing Purity and Consistency

The monitoring of temperature control and bead sizing uniformity and additive dispersion ratios through automated systems leads to enhanced batch-to-batch consistency which is essential for big projects that need dependable performance results.

Introducing HUASHENG as a Reliable EPS Supplier

Huasheng Qihang (Tianjin) International Trade Co., Ltd. operates as a company which conducts research and development and manufactures and distributes EPS materials. The company operates from Northwest China and provides recycled EPS foam products and high-performance EPS materials while implementing international technology standards and maintaining full environmental control throughout its operations.

Overview of HUASHENG’s Product Grades

HUASHENG provides a wide range of products which cater to various industrial requirements.

Common Grade EPS Materials

The product is suitable for general applications that require standard thermal resistance for protective packaging and disposable containers.

Flame Retardant Grade for Safety-Critical Applications

The grade meets global fire code requirements because of its enhanced fire safety properties which qualify it for building insulation panel applications.

Graphite Grade for Enhanced Insulation Performance

The variant contains graphite particles that reflect radiant heat to achieve superior R-values for energy-efficient building applications.

Environmental Protection Grade for Eco-Friendly Solutions

The production process relies on 100% recycled materials to create products that fulfill green building standards such as LEED and BREEAM.

Carbon Black Grade for Specialized Uses

The material finds application in situations requiring UV protection and attractive color appearance for outdoor decorative items and industrial casings that face extended sunlight exposure.

Customized REPS Products Tailored to Client Needs

HUASHENG works with clients to develop customized solutions that match their project requirements through density optimization and additive blending for logistics and smart industry applications.

Conclusion

In conclusion, EPS foam manufacturers source raw polystyrene mainly from crude oil derivatives. Sourcing involves petrochemical processes and faces price volatility and environmental challenges. Sustainable practices like using recycled materials are rising, with suppliers like HUASHENG offering diverse, certified EPS products.

FAQs:

Q1: What is the original source of polystyrene?

A: Polystyrene originates from crude oil derivatives, where benzene and ethylene form ethylbenzene. Dehydrogenating ethylbenzene produces styrene monomer, which becomes solid polystyrene beads for EPS foam manufacturing.

Q2: Is expandable polystyrene environmentally friendly?

A: Yes, recycled EPS reduces waste and energy use by 30%, supporting a circular economy. Sourced responsibly, it’s more sustainable than standard petroleum-based plastics, using 100% recycled materials.

Q3: Why is HUASHENG a dependable EPS foam manufacturer?

A: HUASHENG excels with advanced technology, ISO-approved environmental management, and specialized EPS for cold chain logistics, energy-efficient buildings, and food packaging, backed by facilities in Tianjin and Gansu.