Closed cell EPS foam has tiny bubbles that are completely sealed and do not connect with each other. This special design gives it strong water protection, firm stiffness, great heat blocking, and good air-tight performance. Because of these benefits, people love using it for keeping water away, making seals and gaskets, warming buildings, packing heavy machines safely, and stopping vibrations. Certainly, it is not very bendy and does not let air breathe through, so some jobs need other materials. But HUASHENG makes special kinds, like the heat-boosting Special Grade G and the fire-safe Grade FS, to fit tough rules and different factory needs.

Understanding the Structure and Characteristics of Closed Cell EPS Foam

The Role of Cell Structure in Foam Material Performance

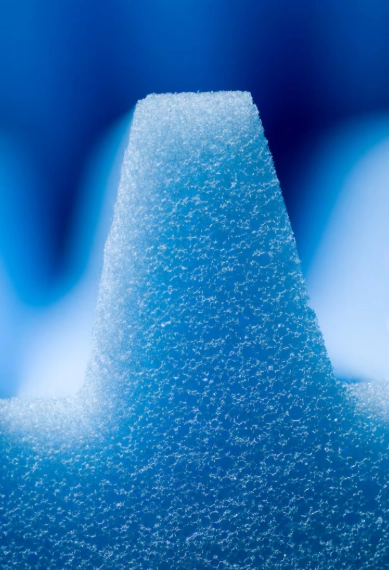

Foams come in many types. Their usefulness depends mostly on how the little cells inside are built. The biggest difference is simple: are the cells open or closed? In closed cell foams, every tiny bubble is fully wrapped up. Nothing flows from one bubble to another. The bubbles sit very close together, yet they stay separate. This setup makes the foam hard and strong. It also stops air and water from passing through easily.

This kind of build brings real benefits. First, it blocks heat very well. Second, it stays tough when things push or pull on it. That is why factories and builders choose it so often.

Closed Cell vs Open Cell: Structural Differences and Functional Implications

People always compare closed-cell foam with open-cell foam. Closed cell EPS foam feels firm and keeps water out. It traps heat better because gas stays locked inside each bubble. On the other hand, open-cell foam feels soft and stretchy. It can wrap around strange shapes easily. However, it soaks up water fast and is not as strong.

So the choice is clear. If you need something stiff and dry, go for closed cell EPS foam. If you want softness and air flow, pick open-cell instead.

Common Types of Closed Cell Foams and Their Compositions

You can find closed cell foams made from different stuff: polyethylene (PE), expanded polystyrene (EPS), ethylene-vinyl acetate (EVA), cross-linked PE, and neoprene. The most common ones are Polyethylene Foam, Beaded Polyethylene Foam, Crosslinked Polyethylene Foam, Expanded Polystyrene Foam, and Neoprene.

Among all these, EPS foam is the star in factories and building sites. HUASHENG makes top-level versions. For example, Special Grade G gives better heat protection. Flame Retardant Grade FS keeps fire danger low. Both work great for building houses, packing goods, and keeping things cold during shipping.

Key Advantages of Closed Cell EPS Foam in Industrial Applications

Water Resistance and Moisture Control

Closed cell EPS foam really hates water. Water simply cannot get inside the sealed bubbles. Even if it rains hard or the foam stays underwater, it stays dry inside. That is why it works so well on land or at sea. Air cannot move through it either. So the foam keeps doing its job for many years, even in wet places.

Structural Rigidity and Durability Under Load

All those packed bubbles make the foam super strong when heavy things sit on it. It does not squash or rip easily. Factories use it to hold big machines. Builders use it under walls. It fights holes, tears, and daily wear without breaking down.

Superior Thermal Insulation Capabilities

Tiny gas pockets inside stop heat from traveling. That is how closed cell EPS foam keeps buildings warm in winter and cool in summer. HUASHENG adds graphite to Special Grade G. The gray color bounces heat rays away. So you need less foam to get the same warmth. It is perfect for cold trucks and super-warm houses.

Air Sealing and Energy Efficiency Enhancement

No gaps exist between the bubbles. Therefore, no air sneaks through. Builders put it around windows, doors, and walls. Cold or hot air from outside stays out. Heating and cooling machines work less. Energy bills go down, and people feel comfortable all year.

Chemical Resistance and Flame Retardancy Options

Most factory oils and cleaners do not hurt closed cell EPS foam. It just ignores them. When fire rules are strict, HUASHENG offers Flame Retardant Grade FS. This kind passes hard fire tests. Yet it still stays strong and keeps water out. It fits nicely in electronics boxes and public buildings.

Limitations of Closed Cell EPS Foam for Certain Applications

Limited Flexibility and Conformability

The foam is stiff for a reason. Stiffness helps it carry weight. But it also means the foam will not bend around curves or odd shapes. If a job needs soft hugging and wrapping, open-cell foam usually works better.

Lack of Breathability for Ventilated Systems

Air and steam cannot pass through. This is good for keeping things dry. However, it is bad if you want the material to let air or vapor move on purpose. So it does not fit filters or breathing walls.

Industrial Applications Where Closed Cell EPS Foam Excels

Gasketing and Sealing Solutions in Harsh Environments

Machines get hot, cold, wet, and dirty every day. Closed cell EPS foam keeps its shape no matter what. That is why it makes perfect gaskets and seals that never leak, even after years of hard work.

Waterproofing Systems for Construction and Marine Use

Builders place it under houses so water stays outside. Boat makers use it for docks that float. HUASHENG created the AquaGuard module. It takes in less than 0.5% water. After floods, people reuse almost 99% of it again and again.

Outdoor Commercial Seating and Marine Upholstery Applications

Sun and salt destroy normal foam fast. Closed cell EPS foam does not care. Cafes, parks, and boats hide it inside seats and cushions. Everything stays firm and dry for many seasons.

Thermal Insulation in Buildings & Fenestration Systems

Walls and windows filled with closed cell EPS foam save a lot of power. In the GreenBuild Eco-city project, HUASHENG flame-retardant EPS raised energy savings by 14%. Workers also finished 18 days quicker than with old materials.

Protective Packaging for Heavy Equipment & Electronics

Big machines and small gadgets travel far. Closed cell EPS foam catches shocks and stops parts from banging together. HUASHENG EcoPack boxes are 100% recyclable. Companies save 28% money and look greener to customers.

Vibration Damping & Acoustic Isolation Applications

Noisy machines shake hard. A layer of closed cell EPS foam under them eats the shaking and quiets the noise. Car makers and factories both use it to keep things calm and steady.

Choosing the Right EPS Foam Product from HUASHENG Based on Application Needs

Special Grade G – For Enhanced Thermal Efficiency Requirements

Special Grade G material has tiny graphite bits inside. They push heat away. So you get more warmth with thinner pieces. Great for super-insulated houses and cold-delivery trucks.

Flame Retardant Grade FS – For Fire-Sensitive Environments

Flame Retardant Grade FS material follows strict fire rules without losing strength or water protection. Perfect for packing electronics or building inside walls where safety comes first.

FAQs

Q: What makes closed cell EPS foam suitable for outdoor applications?

Its sealed bubbles stop water, and the material stands strong against sun and wind. That is why it lasts long in benches, boat seats, and outdoor cushions.

Q: How does HUASHENG’s Special Grade G differ from standard EPS foam?

Special Grade G has graphite bits that bounce heat rays back. So it keeps heat in or out much better than normal EPS.

Q: Can closed cell EPS foam be used where fire safety regulations are strict?

Yes. HUASHENG’s Flame Retardant Grade FS passes tough fire tests while still giving the same strength and dryness protection.