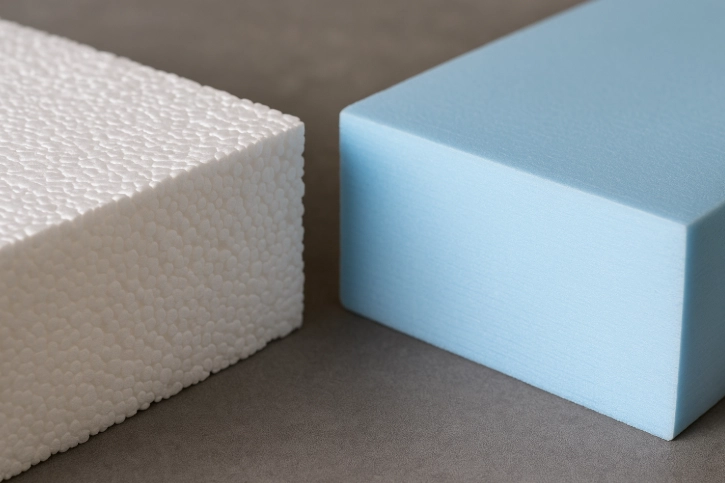

EPS foam and Styrofoam look a lot alike, but they are not the same. People mix them up all the time. EPS foam comes from tiny beads that puff up with steam and then get shaped in molds. That makes it super light, cheap, and you can clearly see the little round beads on the surface. Most folks use it for packing boxes, simple house insulation, and light fill under roads. Styrofoam, however, is a special brand name for XPS foam. Workers make it by pushing hot melted plastic through a narrow slot. The result is a thick, smooth sheet—usually blue or pink—that stays dry and holds heavy weight much better. So, pick EPS foam when you want something cheap and light. Choose Styrofoam (XPS) when the job needs strength and water protection. It all depends on how much weight, how much water, and how much money you have.

Understanding the Distinction Between EPS Foam and Styrofoam

The Common Confusion in Terminology

Many people say “Styrofoam” when they really mean any white foam. That causes a lot of mix-ups. Both start from the same plastic family, and they look foamy and white, so the mistake is easy. Yet the way they are built is totally different. EPS foam grows from beads. Styrofoam is the brand name one company uses for its extruded polystyrene, or XPS. Knowing the real difference helps you get the right stuff for your project.

Why Accurate Material Identification Matters?

Calling the foam by its correct name really matters on real jobs. Pick the wrong one and things can go bad fast. For example, if you put EPS foam underground without a good cover, water can slowly get in and ruin the warmth. XPS, on the other hand, keeps water out almost completely. So in wet places, XPS is the safe bet. Get it wrong and you might have to tear everything apart later.

Differences in Manufacturing Processes

How EPS Foam is Produced?

Workers begin with tiny hard beads. They add steam, and the beads swell up huge—sometimes forty times bigger. Next, they dump these soft beads into big molds and steam them again. The beads stick together and cool down into blocks or custom shapes. That is why EPS foam always shows that beady look when you break it.

How Styrofoam (XPS) is Manufactured?

XPS works in a whole different way. They melt the plastic, mix in some gas, and force the gooey mix through a long thin opening. It comes out as one smooth, thick sheet that cools quickly. There are no beads at all. The sheet is even all the way through and usually bright blue or pink. Real Styrofoam belongs to only one company, even though many brands now sell XPS.

Comparative Analysis of Material Properties

Density and Compressive Strength

EPS foam stays very light. You can lift a huge piece without much effort. But it is not the toughest kid on the block. Styrofoam (XPS) weighs more and can take way more pressure. Drive a truck over it, and it barely notices. That is why XPS goes under floors and busy roads.

Thermal Insulation Performance

Both trap air inside tiny pockets, so both keep heat in or out really well. EPS foam gives steady warmth protection for years. Still, when water shows up, XPS wins easily. Its tight cells keep water away, so the warmth power never drops.

Moisture Resistance and Vapor Permeability

Water is where the big difference shows. EPS foam fights water pretty good at first, but over time it can soak some up if it stays wet. XPS almost never drinks water. In basements, cold rooms, or rainy places, XPS stays strong while EPS might lose some power.

Surface Texture and Visual Characteristics

Snap a piece of EPS foam and you see tons of little balls. The outside feels rough. Cut XPS and it looks clean and smooth, often bright blue or pink. When the job needs a neat finish, XPS looks much better.

Application Scenarios: Choosing the Right Material Based on Use Case

Though EPS and Styrofoam are widely used in various fields, but there are a few differences in thier applications. EPS foam is ideal for lightweight packaging, insulation, and fill, while denser Styrofoam (XPS) excels in structural, moisture-resistant applications like foundations and cold storage.

Common Uses of EPS Foam

Packaging and Protective Cushioning Applications

EPS foam bends a bit and eats up bumps. That is why TVs, dishes, and fridges travel inside it. It is light and costs little, so companies love it.

Construction Insulation Solutions

For regular walls, roofs, and floors, EPS foam works great. It keeps the house warm without adding extra weight to the building.

Lightweight Fill and Geotechnical Applications (Geofoam)

Thicker EPS foam blocks act like super-light dirt. Roads built on soft ground use them so the earth does not sink later.

Recommended HUASHENG Product: Light Flame Retardant Grade-FB

If you pack stuff or warm a house and fire safety matters, grab HUASHENG’s Light Flame Retardant Grade-FB. It stays light, blocks heat well, and fights flames better.

Typical Applications of Styrofoam (XPS) Boards

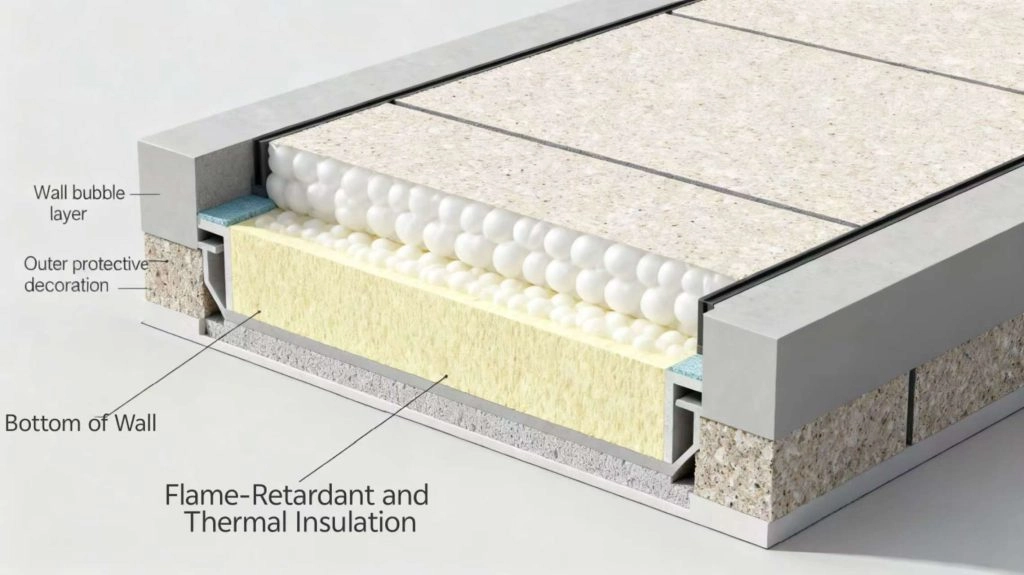

Structural Insulation Requirements in Construction Projects

XPS goes under driveways, house floors, and upside-down roofs. It holds heavy loads and stops frost from pushing the ground up in winter.

Cold Storage and Moisture-Sensitive Environments

Big freezers and cold warehouses use XPS on walls and floors. Water cannot get inside, so the cold stays in and the foam never gets weak.

Recommended HUASHENG Product: Graphite Polystyrene – S32 (Extrusion Method)

For the hardest jobs, HUASHENG’s Graphite Polystyrene – S32 gives top warmth and fights water like a champ.

Addressing Misconceptions About Material Naming Conventions

The Misuse of “Styrofoam” in Common Language

Almost everyone calls white coffee cups or coolers “Styrofoam.” Most of the time they are wrong. Those cups are usually EPS foam. True Styrofoam is the colored hard board for building.

Importance of Correct Terminology in Professional Settings

Builders and engineers have to use the right words. Plans, rules, and safety depend on it. Saying the correct name makes sure everyone gets the strong, dry, or cheap foam they really need.

Selection Guidelines Based on Project Requirements

There are several key factors to be considered when making a choice between EPS and XPS Foam boards.

Load-Bearing Needs

Need something tough under heavy concrete? XPS is stronger.

Moisture Exposure Conditions

Will it sit in wet dirt? XPS keeps water out best.

Cost Sensitivity vs Performance Trade-offs

Want to save cash and the place stays dry? EPS foam is cheaper and works fine.

Ease of Fabrication & Customization Needs

Need funny shapes fast? EPS foam cuts super easy.

FAQs

Q: Is Styrofoam the same as EPS foam?

A: No. EPS foam is white and made from puffed-up beads. Styrofoam is a brand for blue or pink XPS boards pushed out in one smooth sheet. They feel and act different.

Q: Which material provides better insulation—EPS or Styrofoam (XPS)?

A: Both keep heat great, but when water is around, XPS wins. Its tight cells stop water, so warmth stays strong.

Q: When should I choose HUASHENG’s Light Flame Retardant Grade-FB over S32?

A: Go for Light Flame Retardant Grade-FB when you want low price plus fire safety for boxes or easy walls. Pick S32 when you need the best warmth and water protection in tough spots.