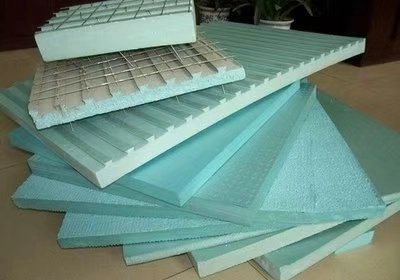

Polystyrene sandwich panels have shifted from being a “cost-driven option” to becoming a performance-driven building envelope choice. When designing or specifying modern facades, roofs, or enclosure systems, the discussion is no longer only about thickness or price, but shifts to the thermal metrics, fire classifications, mechanical behavior, aging stability, sustainability credentials, and long-term project risk. The advantages of these panels become clear only when each factor is considered as part of a complete technical system rather than as an isolated material choice.

Why are polystyrene sandwich panels becoming a default choice for energy-efficient buildings?

Energy laws, carbon reduction goals, and operational cost pressure force you to choose the materials that deliver high thermal resistance per millimeter without complicating construction.

Thermal efficiency

Graphite-grade EPS materials used in high-performance panels demonstrate clear gains over conventional white EPS. For example, some graphite materials, such as S-33 graphite polystyrene that is produced through the extrusion method by HUASHENG, achieve thermal conductivity below 0.033 W/m·K, while ordinary EPS remains around 0.039 W/m·K, translating to more than 20% insulation improvement under comparable thickness. This improvement directly supports thinner assemblies or higher U-value compliance without redesigning the entire wall system.

Structural lightness

The density of materials for construction insulation is typically between 18 and 30 kg/m³, which significantly reduces dead load while preserving dimensional stability. These density ranges are commonly applied to external wall insulation and energy-saving buildings, allowing easier handling on site and reducing demands on the substructure.

Dimensional stability

Modern graphite-grade polystyrene materials also demonstrate improved molecular weight and better compression behavior, which contribute to improving the long-term stability in panel cores. Better stability means less risk of shrinkage, warping, or loss of contact with facings during the service life of the panel.

How does fire performance affect your choice of sandwich panel core?

Fire classification remains one of the most sensitive parameters in project approval, particularly for façades, industrial buildings, and logistics facilities.

B1 / B2 performance

Materials of different grades target different regulatory needs. Certain flame-retardant systems are designed to reach B1-level combustion performance with oxygen index values above 30 or 32, while others are positioned for B2 building material requirements. This allows users to align material selection with local code frameworks rather than over-specifying or under-specifying performance.

F-grade materials

For projects that require reliable B2-class building material behavior, you can consider F-flame retardant grade materials, which follow national standards such as GB/T10801.1-2002 and GB8624-2012, with controlled aging recommendations to ensure stable flame-retardant behavior in finished boards. Its characteristics include good dimensional stability, strong adhesion, uniform cell structure, and suitability for building insulation applications.

Processing reliability

From a production and fabrication perspective, consistent bead size, good flowability of pre-foamed beads, and a wide operating window for automatic and manual molding machines can reduce variability in board quality. That consistency matters because panels fail, which is often caused by process instability.

What role does compressive strength play in long-term panel durability?

Compressive performance is often overlooked during early design but becomes critical once panels are exposed to wind suction, façade anchoring forces, or roof loading.

Load-bearing behavior

Certain high-performance materials are designed specifically to deliver higher compressive strength while maintaining insulation efficiency. European-standard flame-retardant grades used for passive house and construction insulation report compressive strength more than 20% higher than conventional grades, which directly improves resistance to deformation under sustained load.

Aging resistance

Material behavior after foaming and during curing also affects long-term performance. Controlled curing periods based on density and thickness contribute to the full release of residual blowing agents, thus stabilizing mechanical and fire properties. This highlights that durability depends not only on formulation but also on correct processing techniques.

Project reliability

For specifiers or project engineers, higher stability and predictable mechanical performance mean fewer on-site failures, fewer warranty claims, and more confidence in long-term envelope performance.

Why is sustainability now a technical requirement rather than a marketing feature?

Sustainability has moved from optional labeling to measurable engineering criteria, especially for projects targeting ESG compliance, green certifications, or long-term asset value.

Carbon footprint

Advanced EPS systems now integrate recycled raw materials and low-energy manufacturing processes. One industrial example reports that production energy consumption has been reduced by about 30% through smart manufacturing systems and closed-loop process optimization. These reductions directly affect embodied carbon calculations for the projects.

Recyclability

Modern EPS solutions increasingly align with international PS recycling category 6, supporting internal recycling, regranulation, and downgraded reuse, giving you a practical pathway to integrate circular economy strategies into material specifications.

Energy efficiency

Beyond operational insulation performance, manufacturing efficiency also matters. Relevant data shows that the advanced EPS system saves over 20% on energy consumption during molding, and improves overall molding efficiency by over 50%, which is beneficial for the achievement of goals in both environmental and economic projects.

Who is driving innovation behind high-performance EPS systems today?

HUASHENG is a high-tech enterprise specializing in EPS R&D, production, and application across building insulation, prefabricated construction, and energy-efficient envelopes. Our technical platform includes a digital twin laboratory integrating material gene banks and process simulation systems, which support tighter control over density uniformity, compressive strength, and thermal performance. Our innovation in nano-closed pore structure technology reports compressive strength improvements of around 40% compared with conventional materials, which directly addresses structural reliability challenges in panel cores.

Our company also operates advanced production systems using recycled raw materials, achieving waste recycling rates above 95% and lowering production energy consumption by approximately 30%, which supports projects seeking both performance and sustainability alignment.

How can you select the right panel configuration for different project types?

Material selection only becomes meaningful when it is in line with real building use conditions rather than generic catalog values.

Residential facades

Priority is taken to thermal conductivity, fire classification, and long-term stability. Graphite-grade materials designed for external wall insulation and energy-saving buildings provide a practical balance between insulation efficiency and regulatory compliance.

Industrial buildings

For warehouses, plants, and logistics centers, compressive strength and dimensional stability carry more significance. Materials designed for higher mechanical performance help panels maintain integrity under mechanical fixing loads, vibration, and large-span façade systems.

FAQs

Q: Are polystyrene sandwich panels suitable for high-rise building envelopes?

A: Yes, provided the core material meets the required fire classification (such as B1 or B2 according to local standards) and demonstrates stable compressive strength and dimensional stability. Technical documentation shows that certain grades are specifically used for external wall insulation and energy-saving buildings, which include multi-story applications.

Q: How much improvement in insulation can graphite-grade EPS deliver compared with ordinary EPS?

A: Data indicate that graphite-grade extrusion grades achieve thermal conductivity below 0.033 W/m·K compared with 0.039 W/m·K for ordinary EPS, representing more than a 20% improvement in insulation efficiency under equivalent conditions.

Q: Does sustainability performance affect material selection in real projects?

A: Increasingly yes. Documented practices include recycling rates above 95%, production energy reduction of 30%, and compliance with international recycling classifications. These parameters now influence procurement decisions for projects targeting ESG, green certification, and long-term asset value.