In today’s changing world of building and insulation, picking affordable yet effective materials is key. Expanded Polystyrene (EPS) panels have become a top choice. They are budget-friendly, adaptable, and great for saving energy. Whether for homes or big projects, EPS offers a solid way to boost heat control while keeping costs low.

What Is Expanded Polystyrene (EPS) and Its Role in Construction

Expanded Polystyrene (EPS) is a light, firm foam made from tiny polystyrene beads that grow when heated. It’s a vital part of modern building work. This is because of its strong ability to keep heat in and its structural perks.

Key Properties of EPS Material

EPS is known for blocking heat well, being sturdy under pressure, and resisting water. Since starting, HUASHENG has used Lanzhou’s location and resources smartly. They built a high-tech production line. They also brought in top-notch EPS foaming methods and precise testing tools. This ensures their products lead in areas like even density, strength, and heat-blocking ability. These traits make EPS perfect for places needing steady heat barriers.

Common Applications of EPS in Building and Insulation

EPS panels are used a lot in wall insulation, roof bases, underfloor heating supports, and exterior insulation finishing systems (EIFS). They have excellent heat-saving abilities. This cuts down energy use in buildings. Beyond construction, EPS also helps in packaging and keeping cold items safe during transport.

Advantages of Using EPS Panels in Construction Projects

EPS panels bring many benefits. They lower energy bills by controlling heat better. They are easy to install because they’re so light. Plus, they last a long time, even in tough weather. They act as a strong heat barrier. This keeps indoor spaces comfy all year. It also reduces the need for heating or cooling systems.

Types of EPS Material and Their Characteristics

To fit different project needs, makers offer various EPS types. Each has special features for specific uses.

HUASHENG EPS Foam Products Include:

Common Grade EPS

This basic EPS works well for standard insulation needs. It’s used where fire resistance or special features aren’t needed. It’s affordable and easy to find.

Flame Retardant Grade EPS

This type is great for places needing extra fire safety. For example, B1 flame-retardant EPS particles (density 22kg/m³) were used in projects to boost safety. They also helped earn LEED Green Building Gold Certification.

Graphite Enhanced EPS

This type has graphite particles added. They reflect heat to improve insulation. HUASHENG offers various EPS types, like Common grade, Flame retardant grade, and Graphite grade.

Environmental Protection Grade EPS

This type focuses on being eco-friendly. It uses recycled materials or green production methods. HUASHENG recycles 300,000 tons of EPS yearly. This saves 1,500,000 tons of crude oil and cuts 1,200,000 tons of carbon dioxide.

Carbon Black Grade EPS

This EPS is made for UV stability or special looks in open areas. It mixes style with strong performance.

Customized REPS Solutions

For unique building or industrial needs, HUASHENG provides tailored REPS solutions. For instance, custom-dyed EPS particles (size 2-4mm) increased sculpture stability by 70%. These works were shown at the Venice Biennale.

Factors That Influence the Price of EPS Panels

Knowing what affects EPS panel costs helps buyers choose wisely for insulation.

Raw Material Costs and Market Changes

Polystyrene resin prices shift with global oil prices and supply chains. Using recycled materials can save money. But this depends on available recycling tech.

Density and Thickness of the Panel

Panels with higher density are stronger but cost more. Thicker panels insulate better but use more material. This raises the price per area.

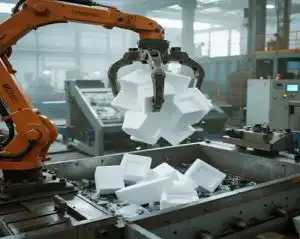

Manufacturing Techniques and Processing Needs

Fancy processes, like adding graphite or fireproofing, make production trickier. This increases costs. HUASHENG’s advanced tech keeps them leading in the industry.

Transportation and Handling Considerations

EPS panels are bulky but light. This can make shipping costly unless packed tightly. HUASHENG’s custom compactors shrink EPS foam to 1/90 of its size for efficient recycling.

Comparing EPS with Other Insulation Materials

There are many insulation choices, like XPS or PU foam. Yet, EPS stays one of the cheapest options.

EPS vs. XPS (Extruded Polystyrene)

XPS has slightly better insulation per inch than EPS. But it costs more. HUASHENG’s range, from Common grade to Graphite grade, closes this gap at a lower price.

EPS vs. PU (Polyurethane Foam)

PU foam insulates better but is pricier per square meter. It also needs trickier setup than EPS panels, which are light and easy to cut.

Cost-Effectiveness Across Different Insulation Options

EPS strikes a great balance between price and performance. It shines when you factor in long-term energy savings versus upfront costs.

Benefits of Choosing EPS Panels for Affordable Insulation

EPS isn’t just cheap. It brings real value in ways that matter for modern building needs.

Thermal Efficiency and Energy Savings Potential

EPS panels have top-notch heat-blocking skills. They lower utility bills by reducing the need for heating and cooling year-round.

Lightweight Structure and Easy Installation

HUASHENG’s panels are super light. This makes them easy to move and set up without heavy tools. It saves time and labor costs during building.

Long-Term Durability and Moisture Resistance

EPS fights off water better than many fibrous insulators. It keeps its insulation power over time, even in damp conditions. This makes buildings more energy-efficient.

HUASHENG: A Trusted Supplier of Quality EPS Materials

With years of expertise, HUASHENG is a dependable name for high-quality EPS worldwide.

Overview of HUASHENG’s Product Range

Product Categories:

- Common grade

- Flame retardant grade

- Graphite grade

- Environmental protection grade

- Carbon black grade

- Customized REPS

Customized REPS Solutions for Specific Project Needs

From green-certified buildings to prize-winning packaging, HUASHENG meets tough demands with custom solutions.

Commitment to Quality, Innovation, and Sustainability

HUASHENG’s success comes from its focus on new ideas. They use digital twin labs and unique recycling tech. This cuts their carbon footprint by over 70%.

Service Support and Global Distribution Capabilities

With bases in China’s industrial centers, HUASHENG ensures fast delivery and support worldwide. Their trade network is based in Tianjin.

Summary and Insights on EPS Panel Pricing

Picking the right EPS type affects both short-term budgets and long-term efficiency in building projects.

How Material Selection Impacts Overall Cost

Choosing advanced types like Graphite grade or Flame retardant grade may cost more upfront. But they save money through better energy use or meeting fire safety rules. Energy savings can rise by 14%.

Making Informed Decisions Based on Project Needs

Every project has unique needs, like strength or green certifications. Matching these with the right EPS type ensures the best return on investment. HUASHENG’s works even appeared at the Venice Biennale.

The Role of Suppliers in Ensuring Value for Money

Working with trusted suppliers like HUASHENG gives access to top materials and expert advice throughout your project. Find the perfect EPS panel or sheet for your needs today!

FAQs:

Q1: Why is Graphite grade EPS pricier than regular types?

A: Graphite grade EPS has tiny graphite particles. These reflect heat waves, boosting insulation a lot compared to standard foam. Extra processing steps raise the price. But they lead to big energy savings over time.

Q2: Are Flame retardant grade EPS panels safe for indoor use?

A: Yes. Flame retardant grades, like B1-rated ones, meet strict safety rules for indoor spaces, like schools or hospitals. They provide structure and fire protection without harmful gases when installed right.

Q3: Can I request custom specs for my building project?

A: Yes. HUASHENG excels at tailored REPS solutions. They adjust particle sizes for art installations or densities for green-certified buildings to meet exact client needs.