Polystyrene insulation, especially Expanded Polystyrene (EPS), is a go-to for builders because it’s strong, cheap, and super versatile. This article dives into how EPS compares to other polystyrene options like Extruded Polystyrene (XPS). It also shines a light on why HUASHENG’s top-notch EPS products, like the S-33 and S-32, are a game-changer for energy-saving construction projects.

Introduction to Polystyrene Insulation

Good insulation is the backbone of energy-efficient buildings. Polystyrene materials are a big deal in construction because they’re tough, long-lasting, and adaptable. You’ve got two main types: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS).

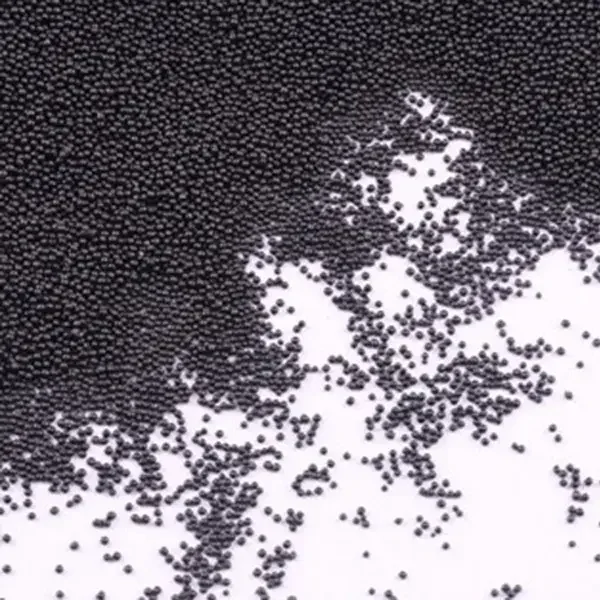

- EPS: Made by steaming polystyrene beads, it’s a lightweight foam with a bubbly texture. Sturdy yet feather-light.

- XPS: Created through extrusion, this one’s denser, with tightly packed cells that keep water out like a champ.

Both are awesome for walls, roofs, and floors. They trap heat, cutting down on energy waste. HUASHENG’s EPS products? They’re next-level, slashing energy use in buildings with their killer heat-blocking skills.

How EPS Performs Technically

Thermal conductivity, or the lambda value (W/m·K), shows how well a material stops heat from sneaking through. Lower numbers mean better insulation.

- Standard EPS: Sits at about 0.039 W/m·K. Solid, but not mind-blowing.

- Graphite-Enhanced EPS: HUASHENG’s S-33 model drops below 0.033 W/m·K. That’s over 20% better than regular EPS—keeps buildings cozy or cool with less effort.

- Long-Term Performance: High-grade EPS, like the S-32, holds its heat-blocking power for years. Barely fades. Its beefier molecular structure and pressure resistance keep it rock-steady, saving energy for the long haul.

- Compressive Strength: Perfect for under floors or flat roofs, EPS handles physical stress like a pro.

- Shape Retention: Graphite-infused EPS stays put, no matter how weights shift or temperatures swing. No gaps, no twists, no insulation leaks.

Moisture and Fire Resistance

Expanded Polystyrene (EPS) is a standout choice for construction due to its impressive ability to combat moisture and fire, ensuring durability and safety in diverse applications.

Moisture Resistance

Water can mess up insulation, but EPS holds its own.

- Standard EPS: Soaks up just a tiny bit of water. But without protection, long-term dampness can take a toll.

- Advanced EPS: HUASHENG’s Flame Retardant Grade – Foffers enhanced water resistance, maintaining structural integrity even in challenging environments.

Fire Resistance and Safety

Fire safety’s a big deal for building materials, and EPS steps up.

- Flame-Blocking Additives: Modern EPS is packed with ingredients to fend off flames. HUASHENG’s Flame Retardant Grade – F hits a B1 fire safety rating with an oxygen index of at least 32. Meets strict national fire codes, no problem.

- Building Code Compliance: EPS products pass tough fire safety tests, making them safe for all kinds of construction jobs.

Environmental Impact and Sustainability

EPS does right by the environment compared to other insulation options.

- Lower Carbon Footprint: It’s kinder to the earth than many mineral-based insulations. Plus, it’s 100% recyclable when its job’s done.

- Energy Savings: By making buildings super energy-efficient, EPS cuts down on greenhouse gas emissions. Greener construction, here we come.

HUASHENG’s all in on sustainable manufacturing. They use smart tech to craft EPS that hits modern green standards while keeping customers happy.

Practical Perks of EPS

EPS is a dream on the job site:

- Light as a Feather: You can cut or shape EPS with basic tools, and it barely kicks up dust. Great for tricky designs or fixing up old buildings.

- Saves Time: EPS goes up faster than stuff like rock wool, sometimes shaving 18 days off a project.

- Super Versatile: HUASHENG’s EPS sheets, like the S-33 and S-32, work everywhere—from home walls to factory floors to eco-friendly passive houses.

To get the most out of EPS:

- Seal up gaps to stop air leaks that could weaken insulation.

- Use glues or fasteners made for EPS, especially in windy spots.

- Add protective layers for underground use to shield against soil moisture.

Where EPS Shines

EPS sheets are crazy adaptable, perfect for:

- Homes—walls, roofs, floors, you name it.

- Commercial or industrial buildings, even heavy-duty factory floors.

- Green projects like passive houses, where HUASHENG’s custom EPS solutions hit high standards.

With different density options and formats, EPS can be tweaked to fit any project’s specific demands.

EPS vs. Other Insulation Materials

How does EPS stack up against stuff like fiberglass or rock wool?

- Weight and Handling: EPS is way lighter and easier to install than fibrous materials.

- Durability: Unlike some insulations that sag over time, EPS keeps its thermal power and stays solid.

- Heat and Water Resistance: Graphite-enhanced EPS beats out others for heat retention and water resistance. Rock wool might win on soundproofing, though.

XPS is awesome at keeping water out thanks to its dense structure. But EPS matches it on thermal performance for less cash, making it the budget-friendly pick for lots of projects.

Why Go With HUASHENG’s EPS?

HUASHENG’s EPS products, like the S-33 and S-32, blend top-tier thermal performance, toughness, and affordability. They’re built for today’s construction needs, supporting energy savings and green goals. Choosing HUASHENG means picking insulation that delivers big value over time.

Expanded Polystyrene (EPS) is a standout insulation material. It’s got killer thermal efficiency, solid strength, great water resistance, and eco-friendly perks. HUASHENG’s advanced EPS, like the S-33 and S-32 models, brings cutting-edge solutions to construction, saving energy, lasting longer, and meeting global standards. For homes, businesses, or green projects like passive houses, EPS is a versatile, cost-effective, and sustainable choice that beats out many alternatives.

FAQ

Q: Is Graphite-Enhanced EPS Worth the Extra Cash?

A: Yes, it is. Graphite-boosted EPS lifts heat-blocking by over 20%. This brings big energy savings over time, making it a smart buy.

Q: Can EPS Sheets Be Used Underground?

A: Yes, they can. But choose higher-density EPS grades. These offer better strength and water resistance, perfect for underground jobs.

Q: What Certifications Should I Check for EPS?

A: Ensure the product meets EN 13163 (Europe), ASTM C578 (US), or ISO 10456 (global), based on your local building codes.