Ever wondered why some buildings stay chilly in summer without blasting the air conditioning, or why others hold up tougher against wear and tear? It often comes down to the insulation material hidden in the walls. If you’re tackling a construction job—maybe a snug home addition or a huge commercial retrofit—grabbing the right graphite polystyrene (GPS) board can make a big difference. In this guide, we’ll break it all down, compare top models, and guide you to a clever choice that suits your needs.

Analysis of the Core Parameters of Graphite Polystyrene

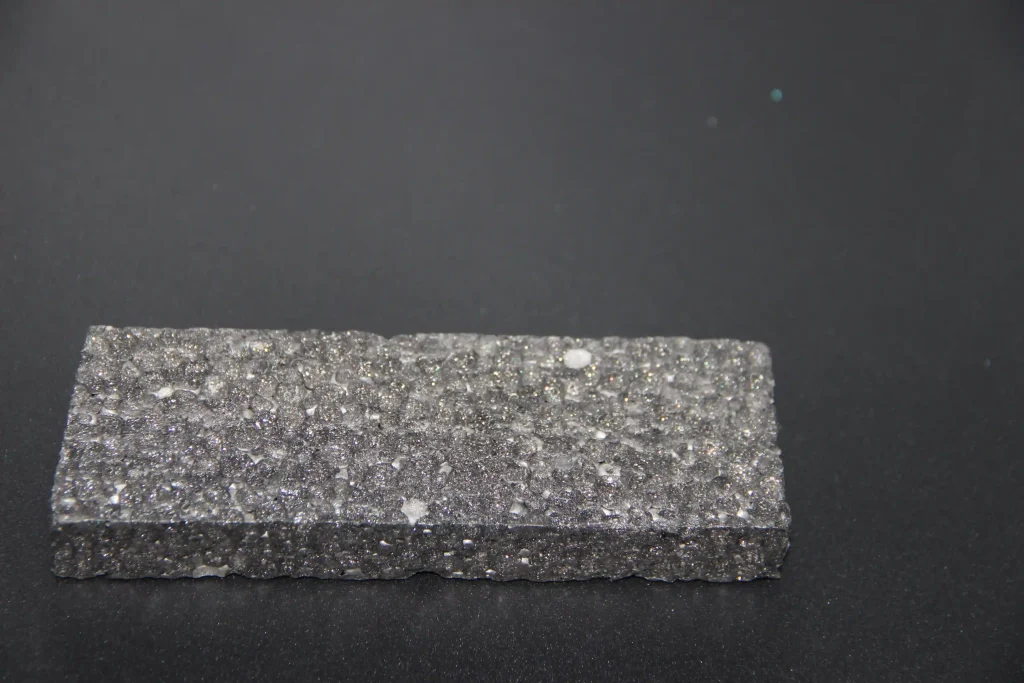

Graphite polystyrene, or GPS, shines in the world of building insulation materials. It blends graphite particles into expanded polystyrene (EPS) for a strong boost. Picture it as graphite enhanced EPS—those tiny graphite bits catch heat better than plain EPS. Still, not every GPS board is the same. You’ve got to weigh key factors to match it to your project. Let’s dig into the main ones.

- Thermal Conductivity: This shows how well the material blocks heat flow. Lower numbers mean better insulation. Standard EPS might hit around 0.039 W/m·K. Graphite polystyrene insulation, though, drops that figure. High-quality GPS can reach 0.032 W/m·K or less. That cuts energy bills by up to 25% in cold climates.

- Apparent Density: Density impacts weight and strength. GPS boards usually range from 15 to 30 kg/m³. Lighter ones are easy to carry on site. Denser boards, however, handle pressure better. Go too low, and it might squash over time. Go too high, and you’re shelling out extra for stuff you don’t need.

- Compressive Strength: Nobody wants insulation that crumbles under foot traffic or heavy loads. Compressive strength is tested in kPa—aim for at least 100kPa for walls, more like 200kPa for floors. Graphite enhanced EPS shines here because the graphite reinforces the structure.

- Flame Retardancy: Safety first. GPS should meet B1 fire ratings, with an oxygen index over 30%. That means it self-extinguishes if ignited. Some cheaper options skimp on retardants, leading to faster spread—I’ve seen reports from fire inspectors highlighting this risk in older buildings.

- Dimensional Stability: Boards that shrink or warp can cause gaps, killing insulation efficiency. Good GPS holds its shape even in humid spots. Tests show less than 0.5% change after exposure to heat or moisture. It’s crucial for long-term projects; imagine redoing a roof because the boards shifted.

- Water Absorption: Moisture is the enemy. Top graphite EPS insulation boards absorb under 2% by volume. Higher absorption leads to mold or reduced R-value. In rainy areas, this parameter can save you from costly repairs down the line.

HUASHENG’s Graphite Polystyrene: Comparison of S-32 and S-33 Models

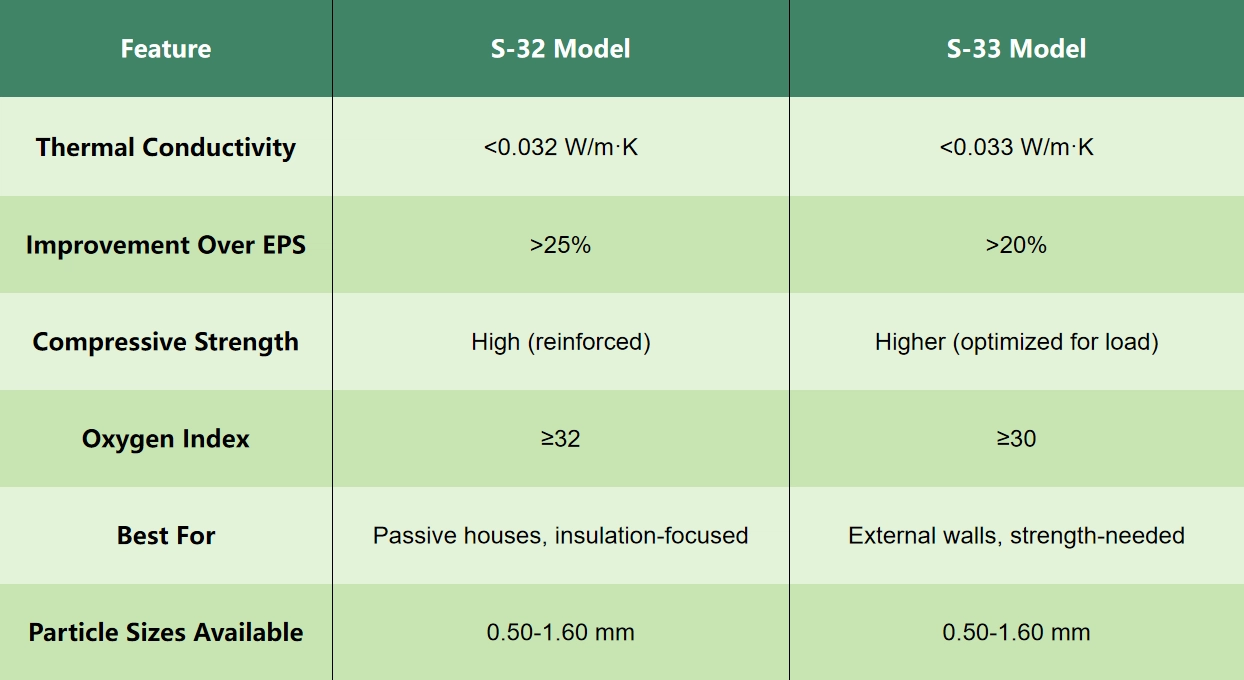

When it comes to reliable options, HUASHENG steps up as a top player in graphite EPS. Their S-32 and S-33 models, made via extrusion, incorporate natural flake graphite for that extra edge. Both are great for building insulation materials, but they cater to slightly different needs. Let’s compare them head-to-head.

The S-32 model edges out in thermal conductivity, clocking in at under 0.032 W/m·K. That’s a 25% bump over regular EPS, perfect for high-energy-saving builds like passive rooms. It uses graphite particles to reflect heat, and its higher molecular weight means better toughness. Builders love it for walls where insulation trumps everything.

On the flip side, the S-33 model shines for spots needing higher compressive strength—think floors or load-bearing areas. Its thermal conductivity is a tad higher at under 0.033 W/m·K, still 20% better than standard, but the real win is in durability. With an oxygen index of at least 30 and good stability, it’s suited for external walls in energy-efficient homes.

For a visual, check this chart breakdown:

Advantages of HUASHENG GPS: Highly Decentralized Technology

What sets HUASHENG apart in the crowded field of EPS manufacturers? It’s their advanced high dispersion technology. Instead of clumping graphite unevenly, they spread it uniformly through the polystyrene. This “decentralized” approach—think even distribution like salt in dough—leads to consistent performance across the board.

HUASHENG’s technology uses extrusion to mix natural flake graphite deeply into the polymer. The result is the boards that perform reliably with no weak spots. Advantages of this uniform graphite dispersion include:

- More stable performance:Every inch insulates the same, reducing hot or cold spots in your building. In tests, HUASHENG GPS shows less than 5% variance in thermal conductivity across samples—way better than patchy competitors.

- Higher strength:The even spread reinforces the structure, bumping compressive strength by 20-30%. I’ve heard from contractors using it in industrial settings; it holds up under heavy machinery without buckling.

- Better consistency:Batch to batch, you get the same quality. This matters for large projects where variability could delay timelines or hike costs.

In addition, their green angle—recycling over 95% of waste and cutting energy use by 30%—fits today’s eco-push. If sustainability is on your radar, HUASHENG’s graphite enhanced EPS delivers without skimping on results.

Buying Guide: You Can’t Go Wrong With This

Here’s a straightforward guide to picking graphite polystyrene insulation without regrets. Follow these steps, and you’ll end up with a board that lasts.

- Identify the Intended Use: Start here. For a home retrofit, prioritize thermal conductivity—go S-32. For commercial floors, S-33’s strength wins. Remember your must-haves: climate, load, and

- Verify Test Reports:Don’t take claims at face value. Ask for third-party certs on flame retardancy, conductivity. HUASHENG provides these upfront, and their oxygen index reports hit 32+ consistently.

- Investigate the Production Process: How’s it made? Extrusion, like HUASHENG’s,ensures even graphite mix. Tour a factory if possible—spot the difference from basic molding.

- Compare Overall Cost-Effectiveness:It’s not just upfront price. Factor in longevity, energy savings. Run the numbers; tools like energy calculators help.

Conclusion

Choosing the right graphite polystyrene (GPS) board is more than a decision—it’s a commitment to your building’s energy efficiency, safety, and long-term durability. The right pick can slash heating costs by up to 25% with better thermal conductivity, like HUASHENG’s S-32 or S-33 models, while ensuring walls and floors stand strong against time and pressure. A poorly chosen board, though, might leave you with gaps, fire risks, or crumbling insulation down the line—issues that hit your wallet and peace of mind hard.

The value of this choice can’t be overstated. A board tailored to your project—whether it’s a passive home or a commercial retrofit—locks in performance and sustainability. HUASHENG’s graphite enhanced EPS, with its uniform dispersion and eco-friendly production, offers that edge. They recycle over 95% of waste and cut energy use by 30%, proving quality doesn’t compromise the planet.

If graphite EPS insulation boards are what you need, reach out to HUASHENG today at info@r-eps.com. We will tailor solutions, maybe even custom specs. Your project deserves the best, so why settle for less?