Expanded polystyrene (EPS) recycle in factory uses centers on cutting waste size, saving resources, and backing round economy aims. The steps cover gathering, washing, pressing tight, and reworking into small balls or resins for reuse in protection, packing, and shaped items. Main problems like low thickness, dirt, and move issues get handled through press machines, good sorting, and nearby recycle setups. By mixing matching materials and tools, firms can cut costs, follow rules, and keep work strength while greatly lowering nature harm.

The Importance of Recycling Expanded Polystyrene in Industrial Settings

Environmental and Economic Drivers for EPS Recycling

Expanded polystyrene (EPS) foam, forms a useful material in many fields because of its light weight and strong protection traits. However, its nature downsides come from hard break-down and high size-to-weight share, putting huge pressure on landfills. Unlike break-down easy materials, EPS foam can stay in dumps for many years, releasing bad chemicals and takes useful room.

Recycle EPS in factory places brings two gains. It eases load on waste handle systems. It also saves new raw items like oil. By recycle EPS foam, pollution lowers. Natural items stay safe. Harm from throw away cuts. It also fits world carbon cut plans. For example, HUASHENG recycles 300,000 tons of EPS each year. This saves 1,500,000 tons of crude and 1,200,000 tons of carbon dioxide.

Firms taking EPS recycle not only cut work costs but also show nature care that matches ESG (Environmental, Social, Governance) needs. HUASHENG stays set on cutting its nature mark through green materials and making steps.

Regulatory and Industry Trends Influencing EPS Recovery

Governments push more bans or limits on one-use plastics, requiring recovery of after-factory polymers. Round economy rules in Europe and Asia push material reuse over throw away. EPS foam recycle plays big part in nature guard and waste control.

Factory workers get push to build closed-loop recycle systems, which is shown clearly in HUASHENG’s work. Through its own “three-circulation” making system, it reaches recycle rate over 95% for waste, allowing large recovery of EPS inside making lines.

Core Principles of Expanded Polystyrene Recycling

Overview of the EPS Recycling Lifecycle

The recycle life cycle for EPS starts with gather from packing waste, protection boards, or build left-overs. After-use and after-factory EPS gather through set plans or on-site recovery units.

Pre-handle covers wash and dry the material, which removes foreign items like glue or food bits. Clean white EPS foam brings highest worth in recycle.

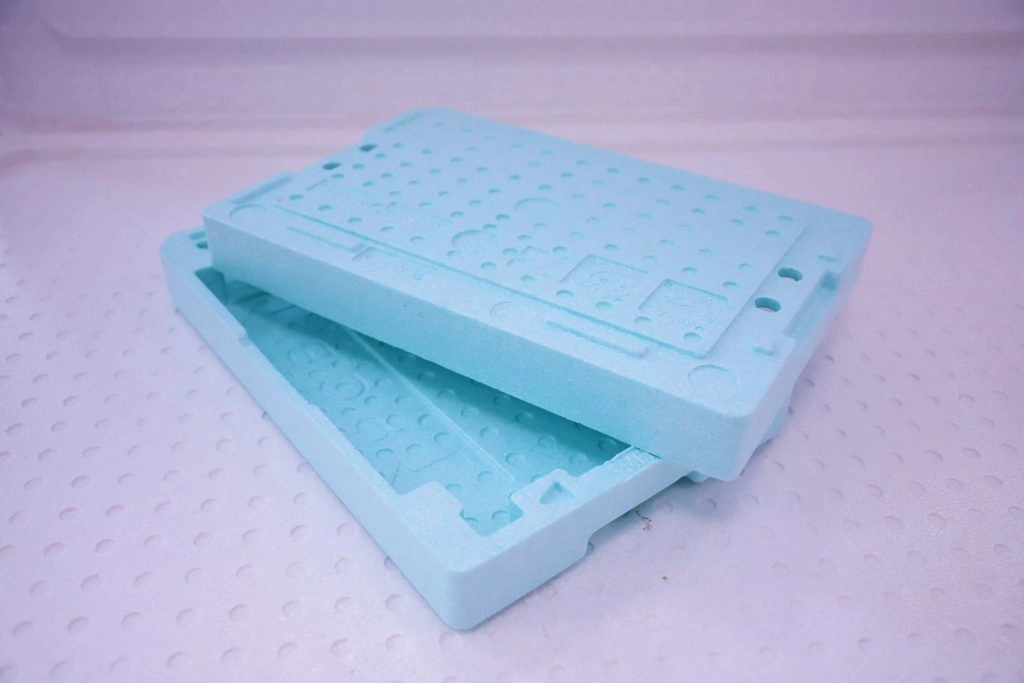

Next stage proves press tight—squeeze the foam to cut size up to 95%. This lowers store room and move costs. At last, the pressed material reworks through melt or ball making into raw items.

The pressed or cut EPS foam then melts with heat and force to form thick blocks or balls.

Transformation of Recycled EPS into New Materials

Once pressed tight and ball made, recycled EPS turns into resin small bits fit for push out or shot molding. These recycled materials repurpose into protection panels, safe packing inserts, plant trays, and other factory uses. By adding recycled EPS foam into new items, makers add to resource protection and waste reduction.

Detailed Breakdown of Mechanical Recycling Processes

Collection and Segregation Techniques in Industrial Environments

Common gather sources cover tool packing, build protection cuts, and factory cushion foams. Clean white EPS sorts for high-level reuse, and colored or dirty foam goes through extra handle steps. The gathered EPS foam sorts to remove any dirt or non-foam items like labels, tape, or soil.

Densification Technologies for Volume Reduction

Compression Equipment Options

Screw-type press machines use turn force to squeeze EPS into bricks. Water force balers serve high-output places where floor room limits but output stays high.

Advantages of Using HUASHENG’s Equipment-Compatible Materials

HUASHENG’s graphite flame retardant grade – FGH-N-HBCD builds for safe handle in press tight without harm release. These materials meet EU REACH and ROHS levels while keeping heat wholeness in squeeze and re-melt parts.

Processing Densified EPS into Reusable Forms

Melting and Pelletizing Methods

Heat rework covers heat pressed EPS into melt state. Then push out into balls follows. These balls use in down-stream uses like protection boards or shaped packing.

Integration with Custom Extrusion Systems

HUASHENG’s Extrusion Customized REPS tunes for re-push out use. It brings steady quality and better recycle in factory making lines. Its custom ball sizes (e.g., 0.65-0.8mm) back tailored push out results for certain field needs.

Challenges in Industrial EPS Recycling and Mitigation Strategies

Logistical Barriers Due to Low Material Density

EPS’s low thickness causes poor move money unless pressed. Polystyrene press machines squeeze large amounts of polystyrene, cutting the amount up to 95%. This greatly betters freight work per kilo moved.

Contamination Issues Affecting Material Quality

Unclean EPS with food waste or glue harms its reuse, ensuring recycled material stays high quality. Good pre-wash setup needs at gather spots.

Infrastructure Gaps in Regional Recycling Networks

Areas without reach to press tools or nearby recyclers often miss good closed-loop systems. On-site spend in press machines fixes this difference.

Strategic Solutions Leveraging HUASHENG Products and Partnerships

Equipment Integration Recommendations

Handle fire-safe EPS needs special tools. Use of press tight fit with HUASHENG fire-safe grades promises safe handle without harm fire safety levels.

Development of Localized Collection Hubs with Industrial Partners

HUASHENG builds shared move among makers using its REPS materials. This tunes gather paths and size money. Setting partnerships between makers using HUASHENG materials can make shared recycle net with tuned move paths.

Value Creation Through Recycled EPS Applications

Industrial Uses of Reprocessed Polystyrene Materials

Recycled polystyrene serves across fields. It goes from heat protection panels in build to decor shapes in build style and packing for electric items.

Uses cover build protection panels, decor shapes, plant trays, and safe packing parts.

Alignment with Circular Economy Goals in Manufacturing

Adding recycled content backs follow with green build proofs like LEED or ISO 14001. This built way meets exact needs of new cool chain delivery while backing round economy plans through recycled material mix.

Benefits of Using HUASHENG-Compatible Recycled Inputs

Enhanced Product Performance

Fire-safe traits keep when using recycled FGH-N-HBCD material in heat uses. This promises safety follow in protection materials without harm recycle power.

Customization Potential through Extrusion REPS

Extrusion Customized REPS allows tailored mixes using recycled content without harm body wholeness. These traits make it perfect for exact making cases.

Recommendations for Industry Stakeholders on Enhancing EPS Recovery Rates

Best Practices for Pre-Recycling Preparation

Gathered EPS should stay dry, clean, and sorted by kind before enter press tools. Make sure gathered foam stays dry, free from dirt, and sorted by polymer kind before press tight.

Steps Manufacturers Can Take to Facilitate In-House Recycling

Fields making large EPS waste should think install screw press machines tuned to their output levels. Train workers on source split betters material gain. Train staff on right split ways at source.

Collaborating with Specialized Material Suppliers like HUASHENG

Use recycle fire-safe grades pre-checked for machine recycle paths. HUASHENG also gives tech help for mix recycled feed into making lines—an key part for long-time green making systems.

FAQs

Q: Can flame-retardant expanded polystyrene be safely recycled?

A: Yes, flame-retardant grades like HUASHENG’s FGH-N-HBCD are designed to be processed safely through mechanical recycling methods such as densification and pelletizing without releasing hazardous substances.

Q: What are the benefits of using Extrusion Customized REPS from HUASHENG in recycled applications?

A: This product is engineered to accept recycled content while maintaining dimensional stability and extrusion performance, making it ideal for industrial reuse scenarios requiring consistent quality.

Q: How can manufacturers reduce costs associated with transporting bulky EPS waste?

A: Investing in onsite densifiers helps reduce the volume by up to 90%, significantly lowering transportation costs per unit weight while improving storage efficiency prior to recycling or resale.