High density polystyrene (HDPS) has emerged as a game-changer in modern construction, offering exceptional thermal insulation and structural resilience. This versatile material, known for its dense, robust foam structure, is engineered to withstand harsh environmental conditions while significantly improving energy efficiency. From foundations to roofs, HDPS enhances building envelopes by minimizing heat loss, resisting moisture, and providing long-lasting durability. In this article, we explore the core features of HDPS, its advantages over traditional insulation materials, and its role in creating sustainable, high-performance buildings.

What Are the Core Features of High Density Polystyrene?

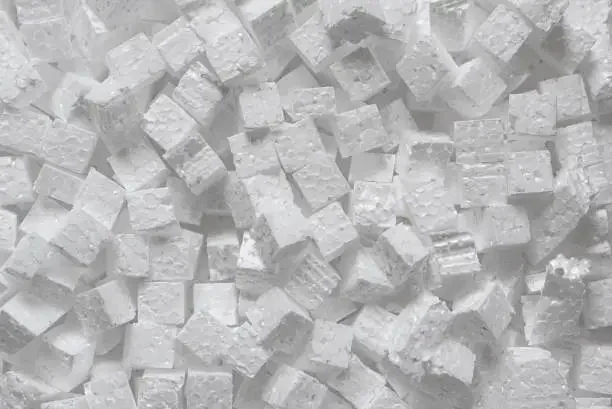

High density polystyrene (HDPS) is a sturdy, tightly packed foam crafted from expanded polystyrene beads. Its structure stands firm like a steadfast soldier. It boasts robust strength against heavy loads and shrugs off water like a duck’s feathers. These traits make HDPS a trusty ally for construction projects that must endure time and harsh weather.

Among its varieties, Black Polystyrene (Suspension)–FGE shines for keeping buildings cozy. During its creation, a method called suspension polymerization weaves in graphite. This special addition acts like a superpower, enhancing the foam’s ability to block heat and toughening it up like armor.

Why Is Heat Flow Resistance Vital for Insulation?

HDPS keeps heat in check thanks to its tightly sealed cells. These cells trap air like tiny balloons, slowing heat’s escape. Black Polystyrene (Suspension)–FGE excels at locking heat in or out of buildings. It slashes energy waste by guarding walls and roofs, paving the way for greener living.

How Does It Stack Up Against Other Insulation Options?

Compared to old-school materials like fiberglass or mineral wool, HDPS dances circles around water damage. It’s feather-light yet brawny when squeezed. Plus, some HDPS types, boosted with graphite or carbon black, reach B1 fire safety levels. This makes them a safer bet in spots where flames might lurk.

How Does High Density Polystyrene Strengthen Building Envelopes?

In walls, HDPS often joins Exterior Insulation Finishing Systems (EIFS). It forms a steady shield that stops heat from sneaking through cracks. Its knack for holding strong under pressure keeps it reliable for years, even in stormy weather.

The material sticks together like glue, sports a sleek surface, and stays true to its size. It’s tough and adaptable, refusing to shrink or twist out of shape. These qualities act like a backbone, keeping walls solid through wild temperature swings.

HDPS thrives on roofs, carrying heavy loads like a champion. It blocks water like a sturdy umbrella. Its rigid frame supports roof layers without buckling. The sealed-cell design stops water from creeping in, which could sap insulation strength over time.

After foaming, HDPS sets in just 4-8 hours. This quick hardening speeds up construction without weakening its heat-blocking magic.

Why Are High Density Polystyrene Blocks Perfect for Sub-Slab and Foundation Use?

Under the earth, HDPS blocks wrap foundations and slabs in a warm embrace. Their dense makeup stops heat from leaking into the soil. They also fend off groundwater like a fortress wall.

HDPS stands up to soggy soil and icy freeze-thaw cycles without losing its insulating spark. This guards buildings against damage from shifting soil or temperature changes, keeping structures solid as a rock.

Strength and steady shape matter underground. HDPS holds its ground like a seasoned warrior, even after years of wet or heavy soil. Its fixed size and mighty strength make it a reliable pick that won’t crumble or warp over decades.

How Can You Boost Energy Savings with HUASHENG Solutions?

If you’re hunting for top-tier insulation for modern buildings, especially eco-friendly homes, HUASHENG delivers. They offer a broad lineup of high density polystyrene products built for stellar performance.

HUASHENG has been harnessing cutting-edge European twin-screw extruder gear, adopted since 2015. They blaze trails in crafting materials for passive house projects. Their range spans standard EPS to graphite-boosted options with ultra-low heat flow. Black Polystyrene (Suspension) – FGE is ideal for electrical components, packaging, and unique black products. Adding carbon black spruces up its look, wards off static, and ramps up fire safety, making it a versatile star for construction needs.

What Should You Think About When Choosing High Density Polystyrene Products?

Choosing the best density hinges on your project’s demands. For instance, P-extra light material is a popular EPS type. It’s perfect for multiple foams to create super-light foam products. This suits jobs where keeping weight low trumps strength. Meanwhile, denser graphite-enhanced grades, like Black Polystyrene (Suspension) – FGE, shine in rugged structural tasks that need extra muscle.

HDPS plays nicely with building parts like concrete slabs, waterproof sheets, vapor barriers, or outer wall covers. Its steady nature and chemical resistance make it a breeze to fit into tricky designs. This teamwork lifts the performance of a building’s outer shell.

Why Is High Density Polystyrene Both Budget-Friendly and Eco-Conscious?

HDPS may cost a tad more upfront than older insulation types. But it pays off like a wise investment. It trims energy bills by blocking heat like a pro. Plus, it needs little care, cutting maintenance costs. Its durability means no frequent replacements, making it a savvy choice for big buildings.

HDPS can be recycled when a building’s life ends. Black Polystyrene (Suspension)-FGE reduces heat flow in insulation boards, slashing energy use over a building’s lifetime. This shrinks the carbon footprint, giving the environment a helping hand.

Where Is Thermal Insulation Headed with This Material Technology?

Smart buildings crave materials that adapt to weather shifts like a chameleon. HDPS’s reliable heat-blocking power makes it a natural fit for high-tech walls or systems that fine-tune energy use on the fly. It blends seamlessly into designs with sensors to save power.

New production tricks, like suspension polymerization, let makers sprinkle in special ingredients like graphite or carbon black. These boosts make HDPS perform better. For example, adding graphite during suspension polymerization gives polystyrene extra perks, like stronger heat resistance and toughness.

FAQ

Q: Can high density polystyrene be used safely near heat sources?

A: Yes. With fire-resistant versions, like those hitting B1 safety marks, HDPS is safe for most building jobs.

Q: Is HDPS good for updating older buildings?

A: Yes. Its light weight makes it simple to install in older structures without extra support.

Q: Does high density polystyrene break down underground over time?

A: No. Its sealed-cell design resists water and freeze-thaw cycles, keeping it strong underground for years.