The construction industry now favors Expanded Polystyrene (EPS) thermal insulation because it provides lightweight construction with affordable costs and superior thermal insulation capabilities. The article investigates EPS insulation durability through an analysis of its material structure and physical attributes and environmental resistance and performance comparison.

What is EPS Thermal Insulation?

EPS thermal insulation consists of rigid polystyrene beads which form a closed-cell structure through expansion and fusion. The construction industry employs EPS thermal insulation for wall insulation and roofing systems and underfloor heating applications because it provides excellent insulation performance at an affordable cost.

Composition and Manufacturing Process

HUASHENG implements international technology through its advanced intelligent production lines. The EPS material shows superior performance through its high density and strong compression resistance and effective thermal insulation capabilities. The REPS production process operates at full scale while using 100% recycled materials and achieves waste recycling rates above 95% and energy consumption reductions of 30% for EPS foam beads and packaging and insulation panels.

Types of EPS Insulation Products

EPS exists in multiple grades which serve distinct purposes in various industries.

Common Grade

The E-standard material functions as a standard EPS material which works well with automatic vacuum forming machines and electric drive forming machines and traditional hydraulic presses. The material serves multiple applications including electrical packaging and thermal insulation materials and fishing floats and handicrafts and decorative items and lost foam casting processes.

Flame Retardant Grade

The product meets the United States Safety Testing Laboratory (UL) certification requirements for F-flame retardant grade. The product demonstrates excellent flame retardant properties and fast pre-delivery speed and wide operating range and good dimensional stability and high strength.

Graphite Grade

The extrusion process at S-33 incorporated natural flake graphite as an infrared absorbing material into polystyrene polymer materials. The thermal conductivity of S-33 reaches below 0.033W/M.K while showing a 20% improvement over standard EPS which has 0.039W/M.K.

Environmental Protection Grade

The FHE-N-HBCD flame retardant grade contains non-HBCD flame retardants which meet EU REACH and ROHS standards. The product provides B1 level flame retardancy through its stable fine bubble structure and consistent size.

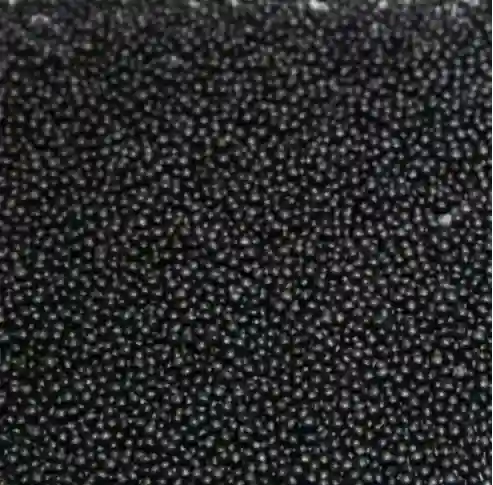

Carbon Black Grade

The construction and industrial sector can use Low thermal conductivity carbon polystyrene FGE material (suspension method) for thermal insulation applications. The material provides B1 fire safety compliance and static protection and soundproofing capabilities.

Key Properties of EPS That Influence Long-Term Performance

The performance of EPS depends on multiple physical elements which affect its long-term functionality.

Thermal Conductivity and Stability Over Time

EPS maintains its low thermal conductivity properties from the beginning until the end of its service life. The thermal conductivity of S-32 is less than 0.032W/M.K which represents a 25% improvement over standard EPS (0.039W/M.K). The values show minimal change when the material remains shielded from UV light.

Moisture Resistance and Water Absorption Behavior

EPS maintains a closed-cell structure which prevents water from penetrating its structure. The material maintains its insulation properties because it does not absorb water in humid conditions.

Compressive Strength and Dimensional Stability

The material maintains its shape under mechanical stress because of its high compressive strength. The EPS material provides superior performance in density and compression resistance which makes it suitable for long-term structural applications.

Factors Affecting the Longevity of EPS Insulation

EPS lifespan depends on both environmental factors and proper installation methods.

Environmental Exposure (UV, Temperature, Humidity)

EPS maintains good resistance to moisture but its surface will degrade when exposed to UV light for extended periods. The use of protective facings or coatings becomes necessary for outdoor installations.

Installation Quality and Building Design Integration

The installation process of EPS can result in gaps or compression that decrease its operational performance. The correct integration of EPS into well-designed building envelopes leads to better energy efficiency and longer product durability.

Mechanical Stress and Load-Bearing Conditions

The compressive strength of EPS materials used under heavy structures and slabs needs to follow particular standards to prevent permanent deformation.

Comparative Lifespan of EPS vs. Other Insulation Materials

The comparison between EPS values enables investors to determine the long-term worth of the company.

EPS vs. XPS (Extruded Polystyrene)

XPS materials absorb less water but their production costs remain higher than those of HUASHENG. The company HUASHENG provides EPS materials with high performance for different sectors including recycled EPS foam that supports circular economic systems.

EPS vs. Mineral Wool and Fiberglass

Mineral wool provides better fire protection than EPS but it does not share the same light weight properties. The R-value of fiberglass decreases when it gets wet whereas EPS maintains its R-value because of its closed-cell structure.

Cost-Effectiveness Over the Product Lifecycle

EPS provides the most economical solution because it requires low upfront costs and needs minimal upkeep during its extended lifespan of decades.

Performance Degradation: What to Expect Over Decades

The product remains durable yet it might experience small changes during its lifespan.

Changes in R-Value Over Time

EPS maintains more than 90% of its initial R-value for decades when it receives protection from UV exposure and water penetration according to research findings.

Structural Integrity After Long-Term Use

EPS maintains its shape in typical situations yet it can experience minor compression when subjected to prolonged heavy loads unless appropriate installation support exists.

Risk of Biological Growth or Chemical Breakdown

EPS provides lightweight energy-efficient solutions that maintain durability because of its inert properties. The material remains resistant to mold growth and chemical degradation when exposed to typical environmental conditions.

Maintenance and Inspection for Extended Service Life

Regular inspections serve as a method to extend the operational life of your insulation system.

Recommended Practices for Long-Term Durability

The panels need to stay away from sunlight and mechanical harm while construction work continues. The storage area needs to maintain temperatures lower than 25 degrees Celsius according to multiple product specifications.

Signs of Deterioration to Watch For

The signs of UV damage and compression and waterlogging will appear as yellowing and sagging of the material which requires inspection or replacement.

Sustainability and Environmental Impact Over Time

EPS serves as a beneficial material for sustainable construction when handled in a sustainable manner.

Recyclability and End-of-Life Disposal

The REPS system operates with 100% recycled materials while achieving 95% waste recycling rates which shows excellent circular economy capabilities. The HUASHENG system provides lightweight energy-efficient solutions that maintain durability standards which align with green building requirements.

EPS in Green Building Certifications (LEED, BREEAM)

HUASHENG delivers high-quality EPS foam products and creates an energy-efficient sustainable environment which supports LEED/BREEAM sustainability targets when integrated into certified systems.

HUASHENG: A Trusted Supplier of High-Quality EPS Solutions

Huasheng Qihang (Tianjin) International Trade Co., Ltd. operates as a research and development and production and distribution company for EPS materials which serves both Chinese domestic markets and worldwide international customers.

Product Range Offered by HUASHENG

HUASHENG’s portfolio includes:

Common Grade

The E-standard material works well for products that have foam levels exceeding 13 g/l and it is commonly used in electrical packaging applications.

Flame Retardant Grade

The F-flame retardant grade meets UL certification requirements for B2 standard building materials.

Graphite Grade

The S-32 series products function as passive room components which deliver substantial improvements to adiabatic performance.

Environmental Protection Grade

The FHE-N-HBCD system employs non-HBCD flame retardants which fulfill both REACH and ROHS regulatory requirements.

Carbon Black Grade

Black polystyrene FGE material provides sound insulation and anti-aging properties which make it suitable for extended periods of use.

Customized REPS Solutions

The company provides individualized service to create special EPS products according to customer requirements while delivering fast responses to their needs.

Commitment to Quality, Innovation, and Environmental Responsibility

The company bases its development strategy on “innovation-driven green intelligent manufacturing” principles. HUASHENG operates with ISO-certified processes which have enabled it to decrease energy usage by more than 30% while establishing new worldwide standards for environmentally friendly manufacturing practices.

Summary of Long-Term Performance Insights

EPS thermal insulation provides a unique combination of cost-effective operation with long-lasting performance.

Overview of Key Takeaways on Durability and Efficiency

EPS maintains its structural integrity for more than 50 years when properly installed because it resists moisture absorption while maintaining consistent R-values. The material maintains its structural integrity for more than 50 years because it resists moisture absorption while keeping its R-values stable.

Suitability of EPS for Long-Term Insulation Needs

EPS provides excellent performance in various climates so it remains a suitable material for residential buildings and industrial facilities that want to achieve long-term energy efficiency with reduced operational expenses.

FAQs:

Q1: How long does expanded polystyrene (EPS) insulation last as an insulator?

A: EPS insulation lasts over 50 years when correctly installed away from UV exposure and mechanical stress. Its closed-cell structure prevents moisture ingress, preserving its R-value and insulating properties.

Q2: Does using recycled EPS affect product quality standards?

A: No, recycled EPS (REPS) maintains equivalent performance to virgin material-based products, achieving over 95% waste recycling rates while upholding high-quality standards.

Q3: Does EPS insulation require upkeep after installation?

A: EPS insulation requires only basic upkeep, ensuring long-term performance with minimal maintenance.