Think about the last time you opened a package. That satisfying rip of tape, the reveal of your new gadget or gift. But then comes the pile of bubble wrap, foam peanuts, and cardboard that heads straight to the trash. It’s a common scene, yet it’s fueling a massive problem. Globally, we generate over 300 million tons of plastic packaging waste each year, with just 9% getting recycled. This linear way of handling things – make it, use it once, toss it – is under fire. Recent changes, like the EU’s Packaging and Packaging Waste Regulation that started in February 2025, call for real shifts. It sets goals to cut packaging by 5% by 2030, 10% by 2035, and 15% by 2040, while making all packaging easy to recycle. In addition, companies all over the globe are making promises to reach net-zero – covering 92% of global GDP and 88% of emissions as of 2025. About 60% of Forbes 2000 firms have joined in, and they push for stuff that keeps products safe without hurting the earth.

EPS foam was developed to address this need. This material mixes good product safety with care for the environment. It comes from EPS polystyrene particles, and 98% of it is air, so it’s both light and tough. As businesses and buyers look for better paths ahead, lightweight EPS stands out as a main helper in creating a circular economy – one where trash turns back into useful things.

The Linear Packaging Problem

The old model of packaging has served us for decades, but its flaws are showing. We produce, ship, and discard without much thought to what happens next. This setup creates mountains of waste and drains resources. To grasp why change is urgent, let’s break it down step by step.

Take-Make-Dispose Model

In this traditional approach, raw materials get turned into packaging, used briefly, then dumped. Plastic production alone hit 408 million tons in 2025, much of it for single-use items. Think of the expanded polystyrene packaging around your new TV – it protects during transit, but often ends up in landfills. The process starts with extracting oil for EPS polystyrene beads, expands them into foam, and shapes them into custom EPS foam pieces. Once delivered, that’s it. No reuse, no recycle in many cases. This cycle ignores the full life of materials. It leads to over 4.4 million tons of plastic waste traded each year globally, shifting problems from one country to another. As demand grows, especially in e-commerce, this model strains supply chains. Lightweight EPS could help, but in a linear system, its potential gets wasted.

Shifting gears, we see how this model hits harder than just the environment. It affects bottom lines and reputations too. Businesses face rising costs from raw materials and disposal fees, while ignoring these issues risks losing customers.

Environmental and Business Costs

The cost is high. Landfills overflow with expanded polystyrene foam, which breaks down slowly if not recycled. In the EU, packaging waste regulations now force companies to rethink, with fines looming for non-compliance. Globally, plastic pollution from packaging adds up – over 300 million tons annually, fueling ocean debris and microplastics. For businesses, it’s also not cheap. Shipping heavy packaging bumps up fuel costs; lightweight EPS cuts that by being mostly air. Yet, without circular thinking, companies miss savings. Take electronics firms: damage rates drop with custom EPS foam, but disposal costs rise if not recycled. In North America, EPS recycling hovers around 40%, saving energy compared to new production.

Ignoring this means higher expenses – one study shows recycling EPS uses far less energy, potentially cutting bills by 50% for manufacturers. Plus, with 1,935 entities pledging net-zero by 2025, staying linear risks falling behind competitors. Beyond costs, there’s a human element. People are demanding better, and that’s reshaping the market.

The Consumer Pressure

Shoppers today check labels for sustainability. Surveys show 78% of global consumers want eco-friendly packaging, influencing buys. In e-commerce, where packages arrive daily, frustration builds over excess waste. Lightweight EPS foam boxes appeal because they’re effective yet light, reducing carbon footprints. But if not recyclable, they turn off eco-conscious buyers. Brands like those in fashion have switched to reusable systems, cutting waste by tons. Consumers push for change through social media and choices, favoring companies with net-zero goals. This pressure isn’t fading; with EU rules mandating recyclability by 2030, ignoring it could mean lost sales. As awareness grows, demand for expanded polystyrene packaging that’s part of a loop rises.

A Circular Vision with Smart Design

Moving away from linear pitfalls opens doors to a system where packaging lives on. Circular design rethinks every step, from creation to end-of-life. It focuses on keeping materials in use, cutting waste, and regenerating resources. This vision aligns with global trends, like the 145 countries eyeing net-zero targets. Lightweight EPS fits here, enabling designs that are smart and sustainable.

- Design for Circularity: Start with the end in mind. Packaging should be easy to collect, sort, and remake. Expanded polystyrene foam, being 100% recyclable, shines here. Use EPS polystyrene beads from recycled sources to close the loop. In practice, this means shaping custom eps foam for reuse in multiple cycles. One case: a company recycled cigarette butts into plastic pallets, showing how waste becomes a resource. For lightweight EPS, grinding old foam into new beads cuts virgin material needs by up to 30%. This design reduces environmental hits and meets EU targets for recycling at scale by 2035. It’s about systems, not just materials.

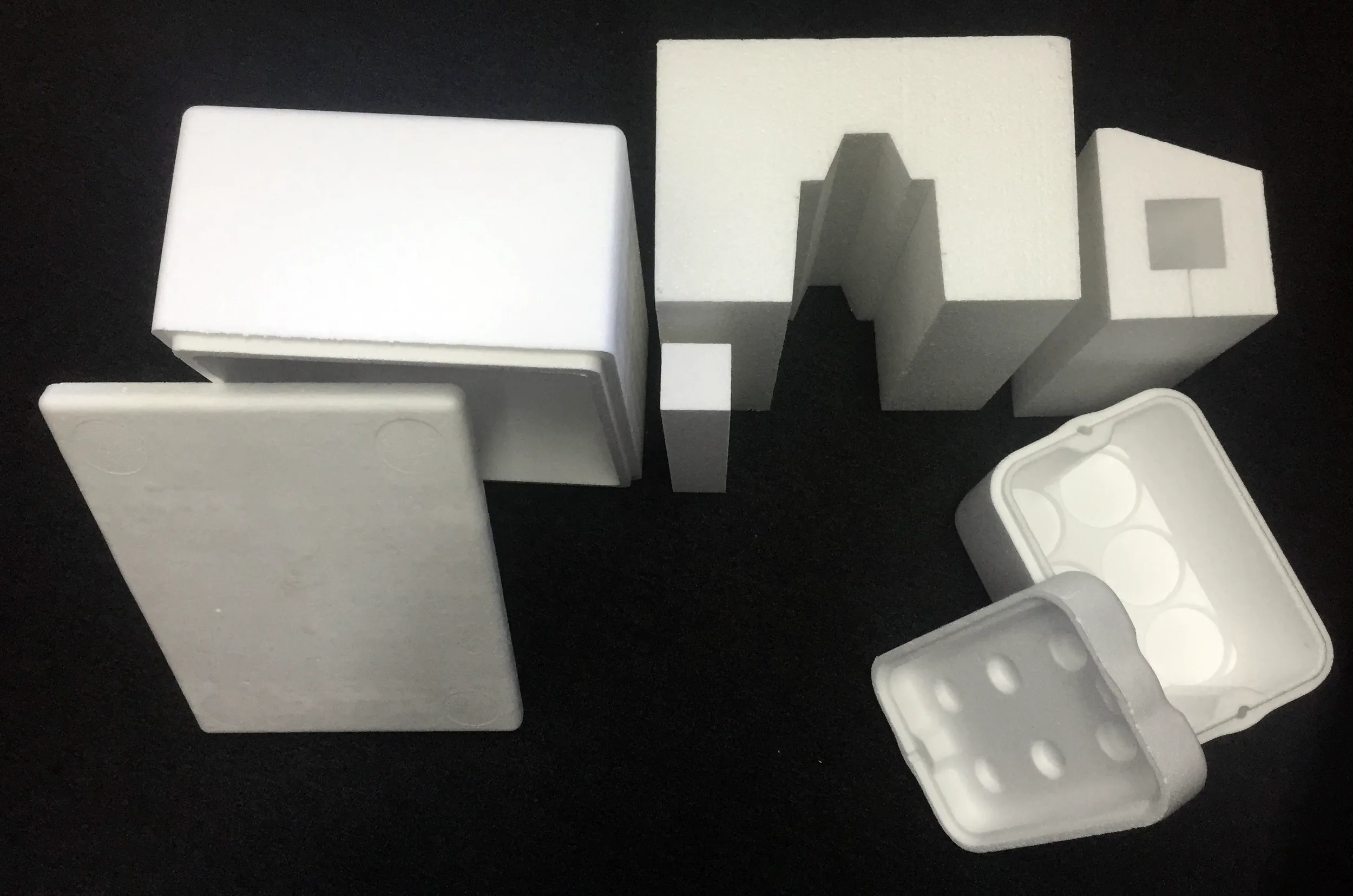

- Design for Less: Why use more when less works? Lightweight EPS excels, weighing little but protecting well. In e-commerce, switching to lightweight EPS foam boxes can slash shipping weights by 20-30%, lowering fuel use. Global plastic trade grew 48% from 2005-2023, but circular designs curb that. EPS foam manufacturers like HUASHENG offer extra-light grades that save resources from the start.

- Design for Function: Packaging has to work first. Lightweight EPS provides cushioning that guards against shocks, ideal for electronics. Its expanded polystyrene structure absorbs impacts, reducing returns by 15% in some cases. Custom EPS foam molds fit products snugly, minimizing voids and waste. In a circular setup, this means designs that disassemble easily for recycling. For instance, refill schemes in stores reuse containers, cutting new production by 25%. Lightweight EPS enables this, being durable yet recyclable.

Lightweight EPS as an Enabler

With these design principles, materials like lightweight EPS step up. From EPS polystyrene beads to finished expanded polystyrene packaging, it supports circular flows. Its low density – 98% air – makes it efficient, and recycling turns it back into usable forms.

Material Efficiency from the Start

Efficiency begins with production. EPS foam manufacturers expand beads with steam, using minimal energy. Recycled content can hit 50%, saving oil. Lightweight EPS foam boxes weigh a fraction of alternatives, cutting transport emissions by up to 90% over their lifecycle. In numbers: producing 1 ton of EPS uses 50% less energy than cardboard equivalents. This front-end savings boosts circularity. And recovery follows. Clean processes make recycling straightforward.

Enabling Cleaner Recovery

At the end of life, lightweight EPS recycles well. In Europe, rates reach 40%, with innovations like pelletizers turning waste into new beads. Expanded polystyrene packaging breaks down without contaminants, unlike mixed plastics. Case studies show chemical recycling of EPS yields high-quality outputs, with life cycle assessments proving lower impacts. This enables closed loops, where old custom EPS foam becomes new.

Case in Point: E-commerce and Electronics

E-commerce booms, with packages needing protection. Lightweight EPS cushions devices, reducing damage. One power equipment firm eliminated 760 tons of waste yearly using reusables. For electronics, expanded polystyrene foam prevents breaks during drops, with custom fits. HUASHENG’s extra-light grade suits this demand. In e-commerce, it cuts costs – lightweight means lower shipping fees. Bullet points on benefits:

- Protects fragile screens and circuits.

- Reduces returns by 10-15%.

- Recycles into new packaging, supporting net-zero.

Building Your Circular Packaging Strategy

Theory is important, but action is key. Businesses can start today. Assess needs, partner up, and share the story.

- Assess and Redesign: Review current setups. Measure waste – perhaps 6 million tons of EPS globally, but only 10% recycled due to logistics. Redesign with lightweight EPS for efficiency. Use tools to simulate impacts.

- Partner for Closed-Loop Solutions: Work with EPS foam manufacturers like HUASHENG for custom EPS foam. And they also handle recycling, turning waste into beads. Investments in circular plastics prove profitable, as case studies show.

- Communicate the Change: Share how expanded polystyrene packaging cuts waste. Use labels, social media. Consumers respond – 78% prefer sustainable brands. Highlight real wins, like energy savings.

Conclusion

The path ahead for packaging isn’t pinned to one wonder material. It’s about crafting systems that think ahead, reuse wisely, and waste little. Lightweight EPS, when designed with circular ideas, acts as a strong tool to lessen harm to the earth and strengthen brands against shifting rules and expectations. It protects goods, lightens loads, and recycles cleanly.

For businesses preparing to take this step, choosing HUASHENG‘s lightweight EPS packaging will open the door to efficiency and sustainable development. Contact us today at info@r-eps.com to begin your environmental journey!