REPS: A Revolution in Recycled Polystyrene

What Makes EPS So Widely Used and Its Drawbacks?

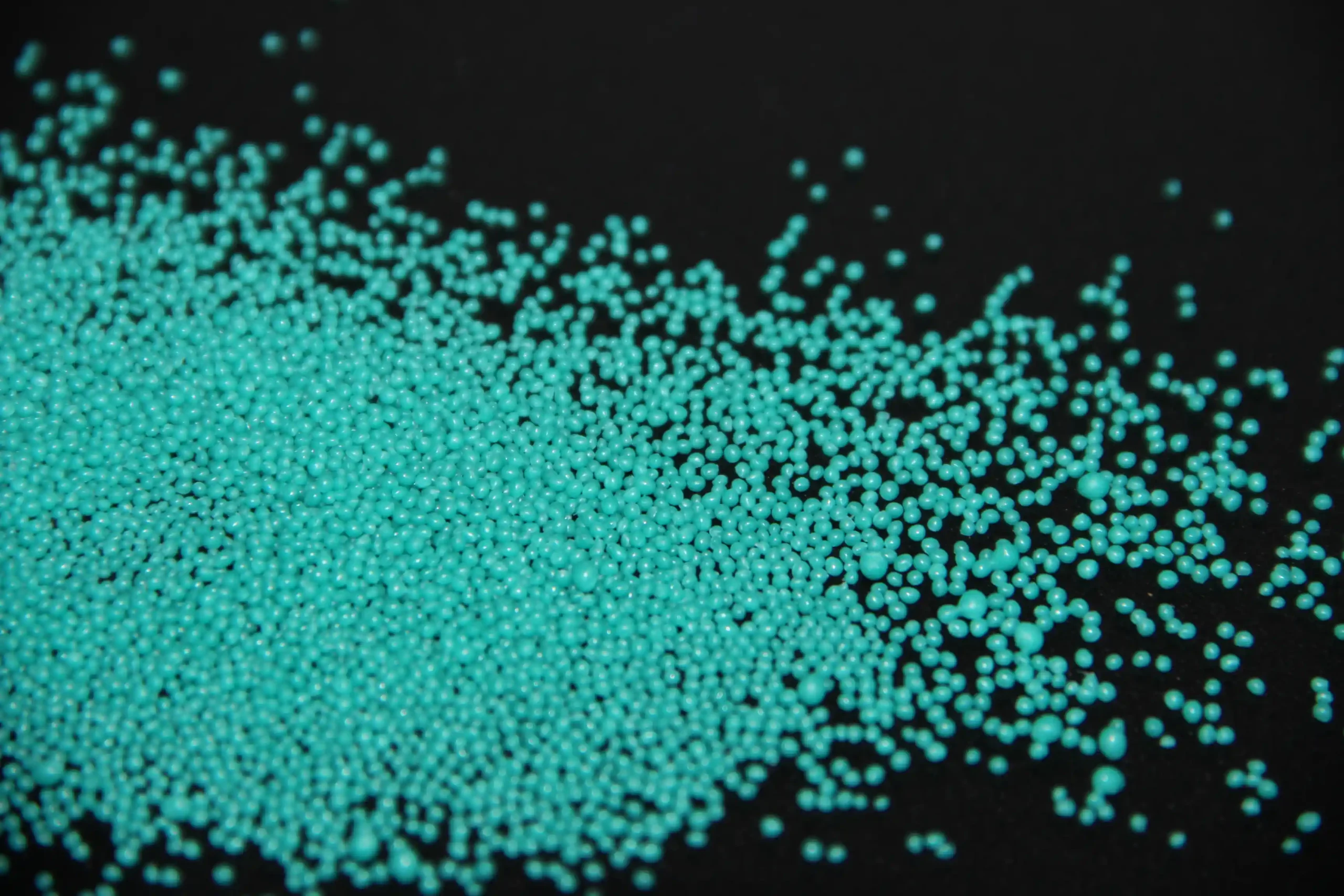

Expanded Polystyrene (EPS) is a rigid, lightweight, and closed-cell foam made from Expanded Polystyrene Beads, usually applied for packaging for its low weight, and ease of molding into different shapes. In addition, due to its excellent thermal insulation properties, EPS is also widely used and welcomed in construction, and its applications go far beyond this.

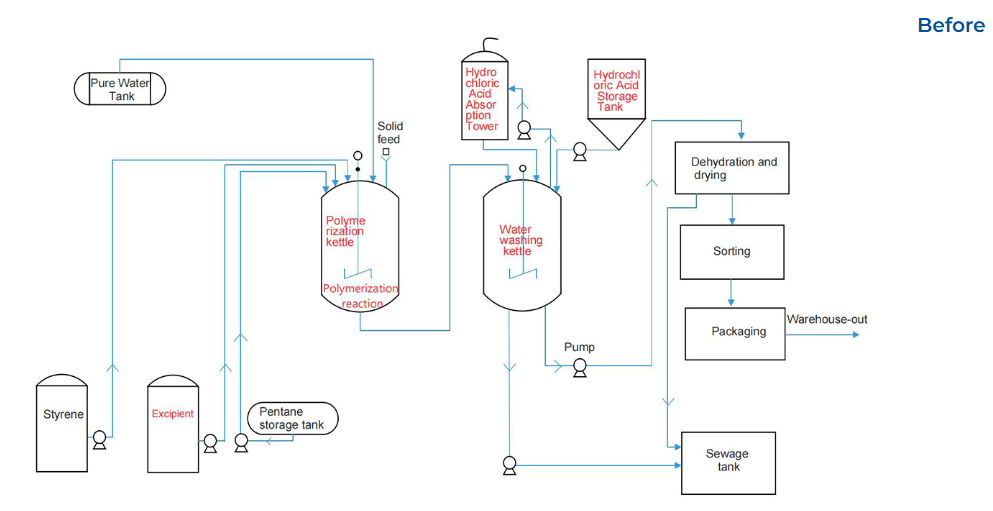

Although polystyrene foam (EPS) has a wide range of applications, its production process places a heavy burden on the environment. As a chemical synthetic material, the manufacture of EPS relies on steam and heat energy to expand the polystyrene insulation beads, which consumes a huge amount of energy; the supply of these energies often relies on the combustion of fossil fuels, which not only directly aggravates air pollution, but also significantly increases carbon emissions, which is obviously contrary to the low-carbon and environmentally friendly trend strongly advocated by the world.

What is more noteworthy is that EPS has the characteristics of being non-degradable, and most of its waste products are sent to landfills for treatment, which not only occupies limited land resources but also poses long-term environmental risks. In addition, the material itself is light in texture and can be easily carried by wind to surrounding areas, causing the pollution to spread. If not handled properly, discarded polystyrene foam plastic fragments may also invade rivers, oceans, and other water ecosystems, causing continuous damage to the aquatic environment and further amplifying its environmental hazards. These problems are obviously in conflict with the environmental protection principles we adhere to.

REPS: an Eco-friendly Alternative to Conventional EPS

While EPS, as polystyrene foam is widely used in packaging, construction, and other industries, recycled expandable polystyrene (REPS) has emerged as a more sustainable alternative.

REPS refers to a new foam material that is derived from recycling wasted EPS materials, and after the process of modifying polystyrene, its properties are more diversified. This innovative material exhibits extremely balanced physical properties – its toughness is enough to cope with frequent collisions during packaging and transportation, and its strength can meet the basic requirements of building structures for load-bearing capacity. This “hard and soft” characteristic enables it to perform well in multiple scenarios. In the field of food-grade packaging, it can be made into a cushioning lining that fits the contour of the food to protect fresh food from extrusion damage, and it can also be formed into a sealed container through precision processing to ensure food safety with its stable chemical properties; in the construction industry, it can not only be used as a filling material for lightweight partitions to improve the seismic resistance of the overall structure, but can also be processed into insulation boards to optimize the energy-saving indicators of the building while maintaining structural strength.

Compared with traditional EPS materials, the performance advantages of this new material are particularly significant: under the same conditions, its impact resistance and lightweight performance are both better, which means that energy consumption can be reduced in the transportation link; at the same time, its temperature resistance range is wider, and the structure can be kept stable in a larger temperature range, far exceeding the limitation of EPS being easily deformed at high temperatures.

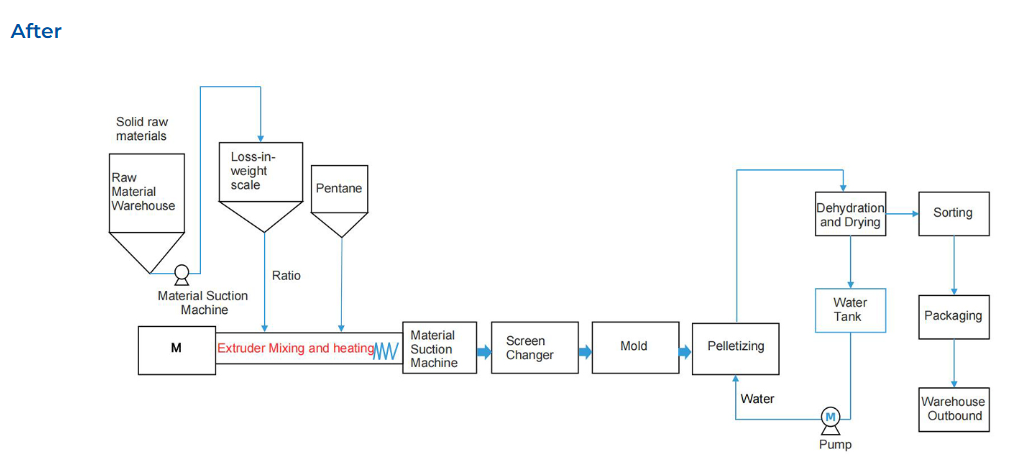

What is more noteworthy is its sustainable nature: the raw materials of this material are completely recycled polystyrene waste, including a large number of discarded EPS foam lunch boxes, home appliance packaging pads, and industrial scraps. During the production process, through advanced melt reshaping technology, these wastes that may have been stored in landfills for a long time are converted into high-value recycled raw materials, which not only greatly reduce the use of virgin plastics but also reduce carbon emissions during transportation through the localized waste recycling system. This “waste to treasure” recycling model not only provides a practical solution to white pollution, but also provides a valuable reference model for the green transformation of the manufacturing industry.

Comparison between EPS and REPS

Impact Resistance:

REPS not only continues the excellent impact resistance of EPS, but also achieves performance upgrades with its unique processing technology. Through the optimization and improvement of the production process, its impact resistance is further enhanced, which enables REPS to provide more reliable protection for fragile items in the transportation of goods and effectively reduce the risk of damage during transportation.

Toughness:

Compared with EPS, REPS exhibits higher toughness, which comes from the mixing process of recycled materials, which gives the material better elasticity and makes it less likely to break when under pressure. This trait makes REPS more competitive and attractive in the construction industry, which has strict requirements on product durability and structural stability.

Application Flexibility:

REPS material perfectly continues the high versatility of EPS and can seamlessly adapt to the existing production system in multiple industrial scenarios. In the field of packaging, it can be molded into various special-shaped buffer structures, whether it is shockproof packaging for precision electronic components or transportation corner guards for large furniture, it can accurately meet the protection needs; when used as a thermal insulation material, its closed-cell structure can effectively block heat transfer, which is suitable for the production of insulation layers for refrigerators and cold storage, and can also be used as thermal insulation filling for building exterior walls, taking into account energy saving and practicality; and in the product manufacturing process, it can be composited with other materials to make various terminal products from children’s toys to industrial accessories, showing strong process adaptability.

Recycling and Low Cost:

REPS is manufactured using a sustainable recycling process, which gives it significant environmental value and economic advantages: the pollution and waste generated during the production process are greatly reduced, which is in line with the concept of green development; at the same time, its manufacturing cost is lower, making recycled EPS beads an economical and sustainable alternative to traditional EPS particles. This eco-friendly and cost-effective feature can bring double benefits to manufacturers, builders, and end users: it reduces economic investment and environmental burden, thereby providing strong support for the development of a circular economy.

REPS Applications Across Key Industries

Packaging

Recycled expanded polystyrene (REPS) occupies an irreplaceable core position in the packaging industry. Its excellent comprehensive performance makes it a reliable guarantee for the safe storage and transportation of various products. From the perspective of micro-structure, the dense independent bubbles inside REPS form a natural buffer matrix. When impacted by external forces, these bubbles absorb energy through orderly compression and gradually attenuate the impact force. This shock absorption performance is particularly prominent in the field of precision electronics. For delicate components such as chips and sensors, even a small displacement may cause functional failure. The customized REPS lining can place each component in an independent “floating protection cabin” through precise cavity design, providing stable protection for the components in scenarios such as bumps in transport vehicles and collisions during loading and unloading.

In terms of thermal insulation, due to expanded polystyrene beads insulation, the closed-cell structure of REPS is like countless miniature thermos bottles, which can effectively block the convection and conduction of heat. For medicines that require strict temperature control, cold chain packaging boxes made of REPS can form a stable low-temperature environment with ice blocks to ensure that the activity of special medicines such as biological agents and vaccines is not affected; in the field of fresh food, it can be used as a transport packaging for tropical fruits to delay the ripening speed through the insulation layer, and it can also build a “mobile cold storage” for ice cream and quick-frozen foods, which can maintain the frozen state of the products even in the high-temperature logistics chain in summer.

The plasticity of REPS provides unlimited possibilities for packaging design. With the help of advanced molding technology, it can be molded into a form that fits the contour of the product perfectly: the packaging pad customized for curved screen mobile phones will reserve a suitable buffer gap at the edge of the screen, which not only avoids the risk of broken screens caused by extrusion, but also allows consumers to experience the precision of “fitting out of the box”; the set packaging designed for glassware adopts a honeycomb partition structure, each cup body is wrapped in a hexagonal REPS groove, and adjacent utensils are completely isolated by elastic inter-layers, even if they accidentally fall, they can effectively avoid collision damage.

This customization capability enables REPS to accurately match the protection needs of different categories: for vulnerable parts such as display screens and control panels of household appliances, REPS can be processed into a three-dimensional frame with reinforcing ribs, taking into account both lightweight and anti-deformation capabilities; for glass-packaged medicines such as oral liquids and injections, it can be made into a grid tray with elastic buckles to ensure that the bottle body is upright and fixed to avoid leakage of liquid medicine caused by tipping during transportation; and for large and valuable items such as pianos and precision instruments, REPS can be combined with wooden pallets to form a composite packaging system with “rigid outside and soft inside”, which absorbs ground impact through the bottom buffer layer and resists lateral extrusion through the side protective plate, fully ensuring the safety of the entire chain from the production workshop to the hands of end customers.

In addition to the protective function at the appearance level, REPS also has excellent thermal insulation performance. For those products that are more sensitive to the storage and transportation environment temperature, such as fresh food and medicine, REPS has become an ideal choice for transportation packaging of such products due to good expanded polystyrene beads insulation properties.

Main Products

- precision instrument packaging

- ceramic lamp boxes

- electronic component containers

- cold-chain insulated packaging

Construction

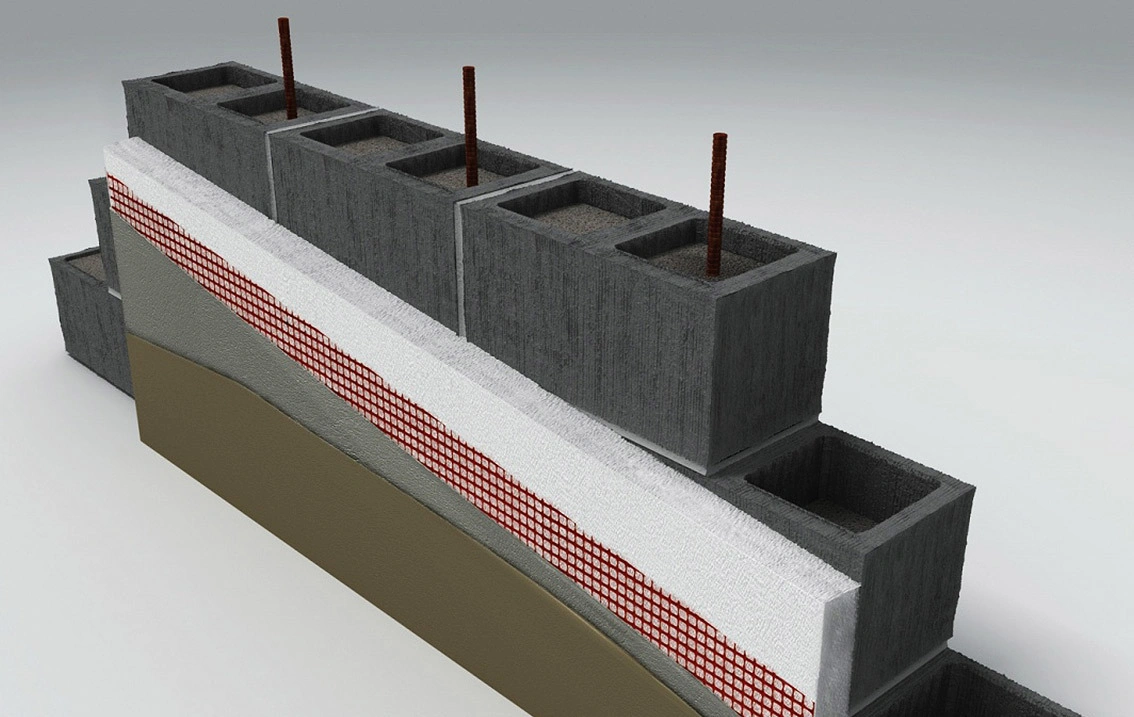

REPS is highly regarded in the construction industry for its reliable insulation performance, moisture resistance, and dimensional stability. It is usually used in the form of expanded polystyrene pellets. REPS materials can reduce heat transfer between walls, roofs, and floors, playing a vital role in improving the energy efficiency of buildings. Its lightweight and strong material are particularly suitable for under-slab insulation, void filling, and infrastructure projects such as highways and embankments.

One of the core advantages of REPS is its stable R-value performance, which means that its thermal insulation performance can maintain high efficiency for a long time without obvious attenuation. Even in scenes with complex and changing environmental conditions, this feature can ensure that it continues to play a stable thermal insulation role, thus providing long-term energy efficiency protection and a comfortable indoor environment experience for the space. In addition, REPS has excellent dimensional stability and can maintain its size and shape under certain loads or special environments, which helps to maintain the structural integrity of building components for a long time. Although REPS has a low density, it has strong compressive resistance and can withstand large weights without deformation, making it ideal for use as a support material for insulation and lightweight structures. In addition, its excellent insulation performance and light weight make REPS materials often used as core materials in precast concrete panels in the construction field. Whether insulating building envelopes or stabilizing soil in road construction, REPS is a versatile and affordable material for both residential and commercial projects.

Main Products

- Flame-retardant insulation panels

- Thermal barrier boards for walls and roofs

- Lightweight formwork and filler blocks

Automotive & Transportation

The lightweight structure and strong impact resistance of REPS materials have also made it widely recognized and applied in the automotive and transportation industries. Fuel efficiency and passenger safety are two key issues in modern vehicle design, and these characteristics of REPS can meet these two needs. In the field of vehicle manufacturing, REPS is often used to fill interior parts, including headrests, door panels, and energy-absorbing plugs, which require both cushioning and structural support. REPS material has excellent energy absorption performance, which is ideal for reducing the risk of collision injuries. At the same time, its lightweight properties can effectively reduce the overall weight of the vehicle, thereby improving fuel efficiency and reducing exhaust emissions, which perfectly fits the green development trend of the automotive industry.

In the automotive manufacturing industry, REPS is also often used in protective packaging during the transportation of parts. With excellent shock absorption performance and good fit, it can ensure that fragile or high-value parts arrive at their destination intact in a complex and changing logistics chain, providing reliable protection for the efficient operation of the supply chain.

At a time when the automotive industry is transforming towards electrification and light-weighting, the application scenarios of REPS have been further expanded, and it is being widely used in structural fillers and some body parts. This application can help manufacturers achieve weight reduction goals without sacrificing vehicle durability and safety, making it one of the key materials to promote the sustainable development of the automotive industry.

Main products

- Interior padding components

- Lightweight fillers and insulation in vehicles

- Protective inserts for parts logistics

With the popularization of the concept of sustainable development, REPS has become the best environmentally friendly material choice for enterprises. It can help enterprises optimize production processes and transportation efficiency while achieving environmental goals. In today’s society, people are increasingly inclined to choose materials with excellent performance and environmental performance.

REPS material cleverly combines excellent durability with flexible versatility, precisely matching the current market’s growing demand for economical and environmentally friendly materials. Whether in the field of precision packaging, building a solid protective barrier for delicate components such as electronic chips and optical instruments; or in building energy-saving scenarios, as a thermal insulation layer to improve the energy efficiency of buildings; or in the manufacture of lightweight automotive parts, while reducing the weight of the vehicle body to ensure structural strength, REPS can easily adapt to a variety of usage needs. This combination of durability, cost advantages, and environmental responsibility makes it a well-deserved future-friendly material, providing a reliable material solution for the sustainable development of various industries.

Bespoke REPS Solutions: Maximizing Efficiency for Your Unique Needs

Recyclable expanded polystyrene has become an ideal material across multiple industries with its triple advantages of lightweight, excellent cushioning capacity, and efficient thermal insulation performance. In the field of packaging, it is a “bodyguard” for fragile and high-value goods. Through the precise fitting structural design, it can form a solid protective barrier during transportation, and its impact resistance far exceeds that of traditional packaging materials, minimizing the risk of damage to goods. For the automotive and transportation industries, the lightweight advantage of REPS directly helps improve fuel efficiency, while its stable physical properties can enhance vehicle safety protection, finding the perfect fulcrum in the balance between cost reduction and safety. In the field of construction, it is an all-round player that combines “strength” and “cost-effectiveness”: it can not only provide reliable structural strength for building structures, but its excellent thermal insulation performance can also significantly reduce building energy consumption, helping construction parties to easily meet strict energy and safety standards, while controlling costs and injecting sustainable development genes into the project. Please contact HUASHENG to make your products with environmentally friendly and affordable materials for the future.

Conclusion:

REPS has become a representative of future materials with its excellent performance and persistent pursuit of environmental responsibility. HUASHENG has always been adhering to advanced environmental protection concepts and is committed to the development of green intelligent manufacturing. In the production and manufacturing process of REPS materials, it insists on sustainable recycling methods, providing companies with a way to reduce their carbon footprint while improving product quality.

Seeking the Best REPS Products? Look Here!

Contact HUASHENG at info@r-eps.com for customized REPS solutions! We’ll help your business succeed in today’s environmentally conscious world and work together to create a more sustainable future.