Les panneaux en polystyrène expansé (EPS) sont maintenant un choix solide et efficace par rapport aux matériaux d'isolation rigides standard. Avec la pénurie de matières premières perturbant les chaînes d'approvisionnement, les constructeurs et les entrepreneurs choisissent l'EPS pour son excellent pouvoir de blocage thermique, son faible coût et ses nombreuses utilisations. EPS est approuvé par l'usine mutuelle, détient des certifications UL et suit les codes de construction en tant que produit fiable qui fonctionne bien pendant des années. Cet article examine le maquillage, les avantages, les inconvénients et les aspects écologiques de Panneaux EPSIl les compare également à d'autres types d'isolation rigide courants.

Qu'est-ce que les cartes EPS et comment elles fonctionnent comme isolation

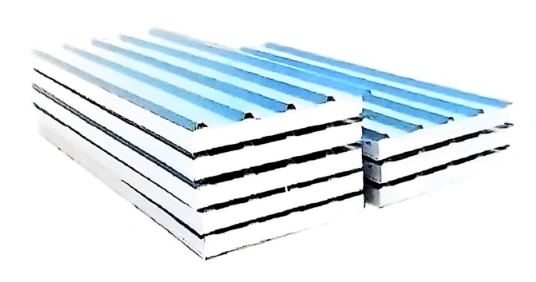

Les panneaux EPS sont créés en chauffant les perles de polystyrène à la vapeur et en les formant en panneaux plats. Leur capacité à maintenir la chaleur à l'intérieur ou à l'extérieur provient de l'air piégé à l'intérieur de leur structure.

Composition et structure des cartes EPS

L'EPS est composé à 98% d'air et à 2% de polystyrène. Cela forme une configuration à cellule fermée qui empêche la chaleur de se déplacer. Le matériau P-extra léger, un type d'EPS de qualité commune, fonctionne bien avec les machines de formage sous vide automatiques, les presses hydrauliques standard et différents grands outils de moulage.

Caractéristiques thermiques de l'EPS

L'air piégé dans l'EPS réduit considérablement le flux de chaleur. EPS donne la meilleure valeur R pour l'argent et maintient cette valeur stable au fil du temps. Les types spéciaux, comme le Graphite Grade EPS, réduisent encore plus le débit thermique. Par exemple, le grade S-33 a un débit thermique inférieur à 0,033 W/m·K. L'EPS standard est de 0,039 W/m·K. Cela rend le S-33 environ 15% mieux à bloquer la chaleur.

Comparaison avec d'autres matériaux d'isolation rigides

Contrairement au XPS (polystyrène extrudé) ou au Polyiso (polyisocyanurate), qui peuvent nécessiter plusieurs couches pour l'épaisseur ou perdre la valeur R au fil du temps, les panneaux EPS peuvent être plus épais que quatre pouces en une seule pièce. Ils maintiennent également leur valeur R de manière fiable.

Évaluer les avantages des cartes EPS

Au fur et à mesure que le besoin d'options de bâtiment à économie d'énergie augmente, les panneaux EPS présentent des points forts clairs.

Efficacité énergétique et résistance thermique (valeur R)

La valeur R mesure à quel point un matériau bloque la chaleur. EPS offre la meilleure valeur R pour son prix, ce qui en fait une option adaptée au portefeuille. Le Graphite Grade EPS augmente encore cette efficacité.

Léger et facile à installer

En raison de son faible poids, EPS est super léger. Le matériau standard E, un EPS de qualité commune, utilise une méthode de moussage simple pour obtenir une structure légère en un seul coup. Cela rend EPS facile à transporter et à installer, ce qui permet d'économiser des coûts de travail.

Économie pour usage résidentiel et commercial

Par rapport à XPS ou Polyiso, EPS donne des résultats similaires à un prix moins cher par pouce d'épaisseur. Sa variété de grades permet aux constructeurs de choisir des options qui correspondent à leurs budgets. Cela fonctionne pour les maisons et les entreprises.

Limites potentielles de l'EPS comme matériau d'isolation

Bien que l'EPS soit excellent dans de nombreuses situations, il y a quelques défis à considérer lors de son choix.

Concerns d'absorption d'humidité

Certaines idées plus anciennes disent que l'EPS absorbe facilement l'eau. Mais l'EPS moderne absorbe très peu d'eau, généralement moins de 2% en volume. Il sèche rapidement s'il est mouillé. Toutefois, une longue exposition à l'eau sans un bon étanchéité peut diminuer ses performances.

Résistance au feu et considérations de sécurité

La sécurité incendie est très importante pour les matériaux de construction. La qualité retardante de flamme F de HUASHENG a la certification UL. Il répond à la norme de sécurité incendie B2, assurant une forte capacité de blocage des incendies.

Durabilité sous charge et stress environnemental

L'EPS régulier peut se plier sous un poids lourd ou une chaleur ou un froid extrêmes. Pour des paramètres difficiles, des options plus fortes comme FSH-European standard Flame Retardant Grade offrent plus de 20% de résistance que d'autres grades.

Comparaison de l'EPS avec les alternatives d'isolation rigide courantes

Pour choisir la bonne isolation, il est utile de comparer l'EPS à d'autres types populaires, tels que XPS et Polyiso.

EPS vs XPS (polystyrène extrudé)

XPS est souvent utilisé pour sa résistance à l'eau dans les projets souterrains.

Différences dans la résistance à l'eau et la résistance à la compression

XPS peut résister un peu mieux à l'eau au début. Mais l'EPS absorbe très peu d'eau et sèche rapidement avec des barrières appropriées. Cela en fait un bon rival.

Performance dans les applications de qualité inférieure

L'EPS enrichi de graphite, comme la série S-32, convient aux maisons passives et aux bâtiments à haut rendement. Il présente un débit thermique faible, inférieur à 0,032 W/m·K, et une forte résistance à la pression. Cela le rend idéal pour les murs de fondation ou les sous-sols.

EPS vs. Polyiso (Polyisocyanurate)

Polyiso commence avec des valeurs R élevées mais peut perdre de la résistance au fil du temps en raison de fuites de gaz.

Stabilité de la valeur R au fil du temps

EPS donne la meilleure valeur R pour son coût et reste stable. La valeur R de Polyiso chute souvent beaucoup après avoir été installée.

Convient aux applications à haute température

Polyiso gère mieux la chaleur élevée. Mais la qualité de graphite ou de noir de carbone de HUASHENG, comme le polystyrène de carbone à faible conductivité thermique FGE (méthode de suspension), améliore la résistance à la chaleur et la sécurité incendie.

Impact environnemental de l'utilisation de cartes EPS

À mesure que la construction écologique devient de plus en plus importante, il est essentiel de connaître les effets environnementaux de l’EPS.

Recyclabilité et élimination en fin de vie

HUASHENG offre un EPS léger et économe d'énergie qui reste fort. Leur qualité de protection environnementale, fabriquée à partir de mousse EPS 100% recyclée, aide à réutiliser les matériaux. Cela soutient les objectifs écologiques.

Émissions manufacturières par rapport à d'autres matériaux

La production intelligente de HUASHENG et la mousse EPS recyclée réduisent la consommation d'énergie de plus de 30% par rapport à la fabrication d'isolation traditionnelle. Cela réduit l'empreinte environnementale.

Innovations dans la production écologique EPS

Le REPS personnalisé de HUASHENG utilise 100% de matériaux recyclés et réutilise plus de 95% des déchets. Cela correspond aux règles mondiales de construction verte et montre des méthodes de production respectueuses de l'environnement.

Scénarios d'application où l'EPS peut être un choix approprié

La gamme de densités et de types d'EPS le rend parfait pour de nombreuses utilisations.

Isolation murale, toit et sol dans les bâtiments résidentiels

Les panneaux EPS offrent une isolation constante pour les murs, les toits et les planchers. Ils évitent les fuites de chaleur courantes dans le cadre de stud. La qualité retardante de flamme FS de HUASHENG atteint rapidement les niveaux de sécurité incendie B1. Il répond à des codes de construction à domicile rigoureux.

Utilisation dans EIFS (Exterior Insulation Finishing Systems)

Parce qu'ils sont légers et faciles à façonner, les matériaux de qualité retardante à la flamme FB-light fonctionnent bien pour les panneaux à faible densité. Ils sont idéaux pour les systèmes EIFS nécessitant une isolation qui s’adapte au stuc ou à d’autres finitions.

Emballage, stockage à froid et utilisations industrielles spécialisées

La qualité de prototypage B-Rapid est idéale pour l'emballage d'articles électriques et fonctionne avec des machines de formage automatiques. Il est également parfait pour le stockage à froid, où il est essentiel de maintenir une température constante. Cela montre l’utilisation de l’EPS au-delà des projets de construction.

Facteurs clés à considérer lors du choix de l'EPS pour les projets d'isolation

Avant de choisir des cartes EPS, réfléchissez à ces points importants.

Conformité aux zones climatiques et aux codes de construction

Les règles de sécurité incendie et de valeur R diffèrent selon la zone. La qualité retardante de flamme F de HUASHENG, fabriquée avec un taux de mousse de 35 à 75 fois, répond aux normes B2. Cela permet d'économiser de l'énergie dans différents climats.

Compatibilité avec d'autres matériaux de construction

L'EPS s'adapte à la plupart des systèmes de toiture, y compris les colles et les membranes. Choisir le bon type assure qu'il fonctionne bien avec d'autres matériaux.

Attentes de performance à long terme

Choisissez des grades EPS qui gèrent les changements de température. Le grade retardant à la flamme standard FSH-européen a une forte liaison et atteint la sécurité incendie B1 plus rapidement que FS. Cela assure une performance durable.

Introduction à HUASHENG en tant que fournisseur EPS de confiance

HUASHENG est leader dans les solutions polymères avancées. Ils fournissent une isolation EPS de haute qualité pour les besoins du bâtiment.

Aperçu de la gamme de produits de HUASHENG

HUASHENG propose une gamme de grades EPS pour des projets spécifiques:

Grade commun, Grade retardant à la flamme, Grade de graphite

- Classe communeInclut un matériau P-extra léger pour une isolation intérieure abordable.

- Grade retardant à la flamme: comprend le grade retardant à la flamme F, répondant aux normes B2.

- Graphite Grade: comprend le polystyrène FGE-Graphite (méthode de suspension) et le polystyrène graphite S-33 (méthode d'extrusion) pour l'isolation supérieure.

Qualité de protection de l'environnement, qualité de noir de carbone, solutions REPS personnalisées

- Grade de protection de l'environnement: comprend le grade retardant à la flamme FHE-N-HBCD, fabriqué à partir de matériaux 100% recyclables.

- Catégorie noir de carbone: comprend le polystyrène noir FGE (méthode de suspension) pour la résistance aux UV.

- REPS personnalisés : solutions personnalisées avec densité spécifique et renforts pour les besoins du client.

Engagement envers la qualité, l’innovation et la durabilité

HUASHENG met l'accent sur la "fabrication intelligente et écologique axée sur l'innovation". Leurs méthodes certifiées ISO et leurs lignes de production modernes fournissent des solutions EPS personnalisées dans le monde entier. Ils équilibrent les performances et les pratiques écologiques.

Conclusion

Les panneaux EPS sont une alternative robuste et économique à l'isolation rigide traditionnelle. Ils offrent une grande résistance à la chaleur, un faible coût et de nombreuses utilisations, ce qui les rend idéaux pour les constructeurs confrontés à des pénuries de matériaux. Les qualités de HUASHENG - qualité commune, qualité retardante à la flamme, qualité de graphite, qualité de protection de l'environnement, qualité de noir de carbone et REPS personnalisé - répondent à divers besoins de projet avec efficacité énergétique et durabilité. Bien que l'humidité et la sécurité incendie nécessitent une attention, une utilisation correcte assure la fiabilité. Leur production écologique et leur recyclabilité favorisent la construction verte. Pour les maisons, les entreprises ou les entrepôts froids, les panneaux EPS offrent une valeur durable, ce qui en fait un choix intelligent pour la construction d'aujourd'hui.

Questions fréquentes

Q1: Le polystyrène expansé est-il sûr pour les maisons?

R : Oui. La qualité retardante de flamme F de HUASHENG a la certification UL. Il répond aux règles de sécurité strictes pour les maisons lorsqu'il est installé correctement.

Q2: Est-ce que l'eau endommage les performances de la carte EPS?

R: Pas beaucoup, si bien géré. L'EPS absorbe peu d'eau, moins de 2% en volume, et sèche rapidement. Un bon étanchéité le permet de fonctionner bien dans les endroits humides.

Q3: L'EPS recyclé peut-il être aussi bon que le nouvel EPS?

R : Oui. La qualité de protection de l'environnement de HUASHENG, fabriquée à partir de matériaux 100% recyclés, réduit la consommation d'énergie d'environ 30%. Il fonctionne tout aussi bien que le nouvel EPS.