Les panneaux d'isolation en polystyrène expansé (EPS) sont populaires dans de nombreux domaines en raison de leur poids léger, de leur résistance et de leur capacité à maintenir la chaleur à l'intérieur ou à l'extérieur. Mais avec le monde se concentrant davantage sur le respect de l'environnement et la réduction des ordures, trouver comment manipuler et réutiliser l'EPS est devenu une grande affaire. Cette pièce plonge dans les effets environnementaux des déchets EPS, les moyens de les recycler et comment les entreprises aiment HUASHENG nous ouvrons la voie à de nouvelles idées pour des solutions EPS recyclées (REPS).

Vue d'ensemble du polystyrène expansé et de son impact sur l'environnement

Qu'est-ce que le polystyrène expansé (EPS)?

Le polystyrène expansé est une mousse dure à cellules fermées faite de minuscules perles de polystyrène. C'est principalement de l'air - environ 98% - et seulement 2% de polystyrène réel, ce qui le rend super léger et excellent pour l'isolation.

Utilisations courantes des panneaux d'isolation EPS dans la construction et l'emballage

Les panneaux d'isolation EPS sont souvent utilisés dans les bâtiments pour maintenir la chaleur à l'intérieur ou à l'extérieur. En ce qui concerne cela, les produits en mousse EPS de HUASHENG se démarquent vraiment. Ils font un travail incroyable pour économiser de l'énergie dans les structures. De plus, pour l'emballage et l'expédition, HUASHENG offre des options de mousse EPS légères mais fortes. Ceux-ci maintiennent les objets en sécurité pendant qu'ils sont déplacés.

Défis posés par les déchets EPS dans les décharges et les environnements naturels

Même si l'EPS est pratique, il cause de grands problèmes pour l'environnement. Il ne se décompose pas naturellement, il peut donc rester dans les décharges pendant des centaines d’années. En outre, comme il est si léger, le vent ou l’eau peuvent facilement l’emporter. Cela contribue à la pollution dans des endroits comme les forêts et les rivières.

L’importance du recyclage des panneaux d’isolation EPS

Le recyclage de l’EPS ne se limite pas à réduire les ordures. Il contribue également à économiser des ressources et soutient les objectifs d’un avenir plus vert.

Réduire le volume de déchets non biodégradables

L’EPS occupe beaucoup d’espace dans les décharges parce qu’il est encombrant par rapport à son poids. Le recyclage réduit considérablement ce volume, parfois dans un rapport de 50:1 avec des machines spéciales. Cela libère de l'espace nécessaire dans les décharges.

Conservation des ressources grâce à la récupération des matériaux

Le recyclage nous permet de récupérer des matières premières comme des morceaux de polystyrène par des méthodes telles que le chauffage ou l'utilisation de solvants. Par exemple, l'utilisation d'un solvant comme le d-limonène peut créer un EPS de toute nouvelle qualité. Une autre méthode, appelée pyrolyse, le transforme en morceaux de polystyrène très purs - environ 99,7% purs. Ceux-ci montrent comment nous pouvons réutiliser les choses bien et maintenir la qualité élevée.

Soutenir les initiatives d'économie circulaire

Le recyclage aide à construire un système où les matériaux sont utilisés encore et encore. Certaines usines modernes réutilisent plus de 95 % de leurs déchets. Cela prouve que l'industrie est sérieuse à faire des choses de manière à ce qu'elles puissent être réutilisées du début à la fin.

Méthodes utilisées dans le recyclage EPS

Il existe plusieurs façons à travers le monde de recycler le polystyrène expansé de manière efficace.

Techniques de recyclage mécanique

Le recyclage mécanique utilise des étapes physiques sans changer de quoi le matériau est fait à son cœur.

Procédés de trituration et de compactage

Tout d'abord, l'EPS est découpé en petits morceaux. Ensuite, les machines l'écrasent en blocs serrés, ce qui le rend beaucoup plus petit. Cela aide à le stocker et à le déplacer facilement.

Le retraitement en nouveaux produits

Après écrasement, le matériau peut être fondu et transformé en petites perles. Ces perles sont ensuite utilisées pour faire de nouvelles choses comme des cadres photo, des articles de bureau, ou même des panneaux d'isolation frais.

Approches de recyclage chimique

Le recyclage chimique réduit l’EPS à ses éléments de base pour obtenir des matières premières ou fabriquer de nouvelles choses.

Dépolymérisation et méthodes à base de solvant

La dépolymérisation signifie diviser le polystyrène en petits morceaux d'origine sous des réglages prudents. Les méthodes solvantes utilisent des choses comme le d-limonène pour transformer l'EPS en goo réutilisable. Ces astuces de solvant peuvent rendre l’EPS aussi bon que nouveau, montrant qu’ils sont excellents pour la réutilisation encore et encore.

Innovations dans les technologies de gestion des déchets EPS

Les nouvelles idées comprennent des programmes numériques pour suivre les emballages avec des systèmes RAID et des projets qui transforment les déchets océaniques en matières premières. Il existe également des outils blockchain pour suivre les matériaux du début à la fin. Par exemple, les programmes qui tirent des plastiques de la mer et les transforment en matières premières EPS aident à lutter contre le désordre océanique tout en se nourrissant pour créer de nouvelles choses.

Applications des matériaux EPS recyclés

Le polystyrène expansé recyclé est utile dans de nombreux domaines, pas seulement pour les feuilles d'isolation.

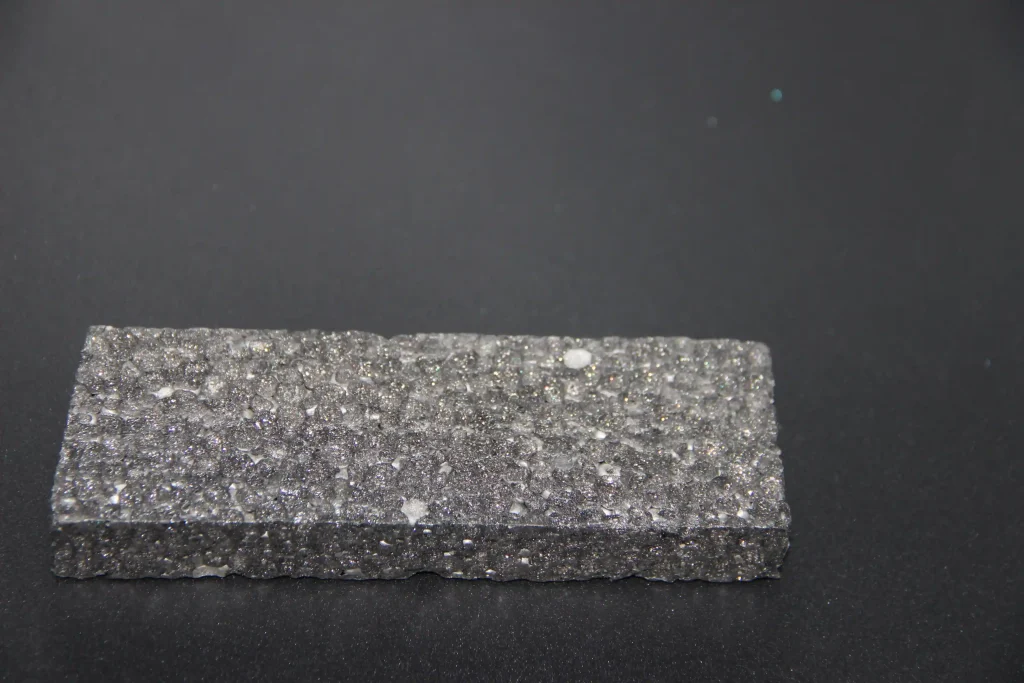

Matériaux de construction et produits d'isolation

Les REPS peuvent être utilisés dans des mélanges de construction légers avec un contenu réutilisé pouvant aller jusqu'à 30 %. Il est également utilisé dans des panneaux mixtes avec aérogel pour un blocage thermique de haut niveau. Ces mélanges de lumière pour la construction sont une façon cool de réutiliser les choses intelligentement.

Solutions d'emballage et biens de consommation

Dans l'emballage, comme EcoPack pour l'électronique, REPS est à la fois bon marché et bon pour la planète. Pensez à un emballage à l'épreuve des chocs pour les gadgets. La solution ? Bits EPS entièrement réutilisables, recyclés jusqu'à cinq fois.

Cas d'utilisation industrielle pour EPS recyclé

Les industries utilisent REPS pour les pièces automobiles, les intérieurs des équipements de sécurité ou même les bases artistiques pour les sculptures où la stabilité est plus importante que l'apparence. Pour les bases d'art, le correctif est des bits EPS personnalisés, de taille 2-4mm.

Défis et limites du recyclage EPS

Même avec la nouvelle technologie, il y a toujours des problèmes difficiles qui ralentissent l'utilisation large des options REPS.

Problèmes de contamination lors de la collecte et du traitement

Des morceaux de nourriture ou des ordures mélangées peuvent gâcher le recyclage. Les outils de tri doivent être meilleurs pour traiter les objets usagés des maisons sans perdre de qualité.

Viabilité économique et demande du marché pour les EPS recyclés

Le nouveau polystyrène est souvent moins cher que les types recyclés parce qu’il est fabriqué en grandes quantités. Nous avons besoin de règles ou d’habitudes d’achat vertes pour pousser les gens à vouloir plus de produits recyclés.

Logistique de collecte, de tri et de transport

Puisque l'EPS est si grand avant qu'il ne soit écrasé, le déplacer n'est pas intelligent à moins qu'il ne soit rétréci immédiatement. C'est difficile pour les petits utilisateurs qui n'ont pas de machines d'écrasement.

Politiques réglementaires et normes industrielles favorisant le recyclage des EPS

Les gouvernements du monde entier établissent des règles pour promouvoir une meilleure gestion des déchets plastiques, y compris le polystyrène expansé.

Règlement gouvernemental sur la gestion des déchets plastiques

Des règles telles que la directive européenne 94/62/CE sur les emballages fixent des objectifs pour le recyclage. En Chine, la GB/T 40006-2021 donne des lignes directrices claires pour les plastiques réutilisés, y compris les REPS, qui aident à atteindre des objectifs comme ceux de la directive de l'UE.

Initiatives menées par l'industrie pour des pratiques durables

Certaines entreprises choisissent d'obtenir des timbres tels que la validation des revendications environnementales UL 2809 ou la certification GRS. Cela montre qu’ils sont sérieux à propos d’obtenir des matériaux d’une manière verte. Ils sont certifiés selon les normes UL 2809.

Le rôle de la sensibilisation et de la participation du public aux programmes de recyclage EPS

L’implication des gens ordinaires est la clé pour s’assurer que les systèmes de collecte fonctionnent bien à grande échelle.

Systèmes de collecte communautaires

La mise en place de points de dépôt locaux ou de services de ramassage sur le trottoir facilite la participation des familles, sinon elles pourraient simplement jeter de la mousse usagée dans la poubelle.

Campagnes éducatives pour promouvoir une élimination appropriée

Enseigner aux gens quelles mousses peuvent être réutilisées et où les prendre peut vraiment aider. Il augmente la quantité qui est collectée et réduit les ordures qui gâchent les endroits de tri.

HUASHENG: Un fournisseur fiable de produits REPS de haute qualité

HUASHENG est un nom de premier plan non seulement dans la fabrication de choses, mais aussi dans le soin de la planète en réutilisant le polystyrène expansé intelligemment.

Profil de l'entreprise et capacités

Lanzhou Huasheng New Materials Co., Ltd. est une société de pointe axée sur la création, la fabrication et la vente de mousse de polystyrène expansible (EPS). Ils visent à offrir des options EPS respectueuses de la planète pour de nombreux domaines. Ils utilisent des idées nouvelles et des installations de haute technologie comme des laboratoires jumeaux numériques. Actuellement, HUASHENG gère un laboratoire jumeau numérique avec des banques de matériaux et des systèmes de test de processus.

REPS de qualité commune pour les applications générales

Bon pour les besoins de base où la force simple est suffisante, sans ajustements supplémentaires ou add-ons.

Grade retardant à la flamme pour une sécurité accrue

Fix: Bits EPS retardants à la flamme B1 (densité 22kg/m³). Les bâtiments qui utilisent cela économisent 14% d'énergie en plus dans l'ensemble.

Graphite de qualité pour des performances thermiques supérieures

Mélanger avec des bits de graphite qui rebondissent les rayons de chaleur, il est parfait pour les bâtiments nécessitant un excellent blocage thermique.

Protection de l'environnement pour des projets écologiques

Fait à partir de matériaux réutilisés après que les gens l'utilisent, répondant à des règles écologiques rigoureuses. Il est idéal pour les bâtiments certifiés LEED et a obtenu la certification LEED Green Building Gold.

qualité noir carbone pour la résistance aux UV

Conçu pour durer longtemps sous la lumière du soleil, il est idéal pour des utilisations extérieures où le soleil frappe dur.

Solutions REPS personnalisées adaptées aux besoins du client

Des bases d'art montrées lors d'événements mondiaux à l'emballage de gadget qui gagne des prix, HUASHENG fait des ajustements personnalisés pour les problèmes des clients avec des tailles et des poids exacts. Leurs œuvres ont été présentées à la Biennale de Venise et ont remporté le German iF Design Award 2024.

Questions fréquentes :

Q1: Quels sont les avantages du recyclage des panneaux d'isolation EPS?

R: Le recyclage réduit une tonne d'espace d'enfouissement et économise des ressources en tirant les matériaux à travers des étapes telles que le chauffage ou la dissolution. Il aide également à construire un système où les choses sont réutilisées dans des domaines tels que la construction ou l'emballage de gadgets.

Q2: Tous les types de polystyrène expansé peuvent-ils être recyclés?

R: La plupart des types propres, blancs et durs de l'emballage ou de la construction peuvent être réutilisés physiquement ou avec des produits chimiques. Mais les mousses alimentaires sales peuvent nécessiter une manipulation spéciale en fonction de ce que les endroits locaux peuvent faire.

Q3 : Comment les individus peuvent-ils contribuer à une meilleure gestion des déchets EPS ?

R: Les gens peuvent aider en lavant la mousse usée avant de la jeter, en rejoignant des programmes locaux de ramassage, en la gardant séparée des autres ordures et en ramassant des articles faits de matériaux réutilisés certifiés quand ils le peuvent.