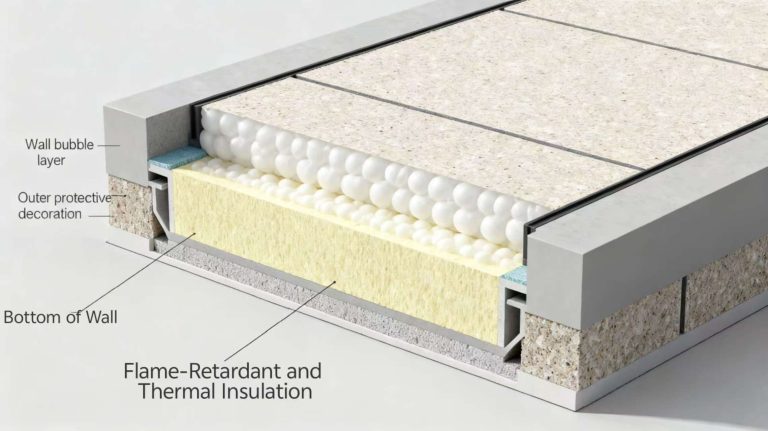

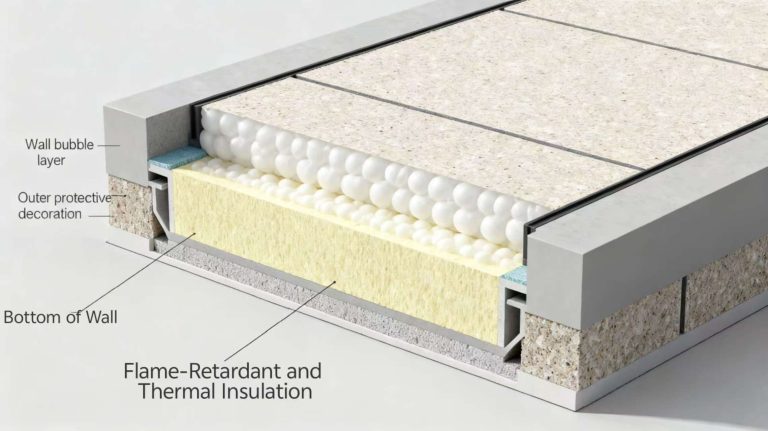

Fb-light flame retardant grade material can be foamed multiple times, the apparent density of bubbles can be less than 10KG/M³, for the production of low density sheet. Fb-flame retardant grade in the processing process to avoid mixing non-flame retardant substances, especially pay attention to must not be mixed with ordinary EPS, these improper processing methods will reduce the flame retardant performance.

Product introduction

Fb-light flame retardant grade material can be foamed multiple times, the apparent density of bubbles can be less than 10KG/M³, for the production of low density sheet.

Fb-flame retardant grade in the processing process to avoid mixing non-flame retardant substances, especially pay attention to must not be mixed with ordinary EPS, these improper processing methods will reduce the flame retardant performance. In order to obtain good flame retardancy, a certain aging time is given to the molded product to let the residual foaming agent escape from the foam body, and the aging period is mainly determined by the foaming agent content, apparent density, product size and other conditions. Recommended aging period of more than 2 weeks.

Product characteristics

1, the pre-delivery speed is fast, saving energy;

2, light products and good flame retardant performance;

3. Good bonding and toughness;

4. Uniform particle size of raw materials, good fluidity of foamed beads;

5, the bead bubble hole is fine and uniform, the product appearance is smooth and smooth;

6, wide operating range, suitable for all kinds of automatic and manual plate making machines;

7, it is recommended that FB-301 do more than 6KG/M plate, can obtain good comprehensive performance products.

| Specification | Particle size | First expansion ratio | |

| Material FB | FB-101 | 1.30-1.60 | 80-110 |

| FB-201 | 1.00-1.40 | 70-100 | |

| FB-301 | 0.75-1.10 | 65-100 | |

| FB-401 | 0.50-0.80 | 45-70 | |

| FB-501 | 0.30-0.55 | 35-50 |

Mainly used for low density plate, small particle size can also be used for general packaging

Copyright © Huasheng Qihang (Tianjin) International Trade Co., Ltd. All Rights Reserved