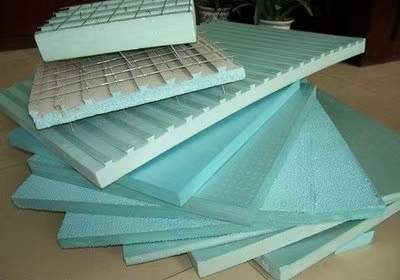

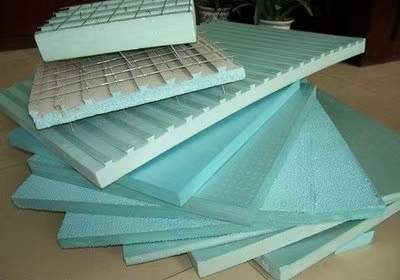

F-flame retardant grade is widely used in EPS foam insulation and EPS wall insulation, offering both thermal efficiency and fire safety. Made from expanded polystyrene beads, F-flame retardant grade EPS insulation material keeps panels lightweight yet durable, unlike ordinary boards that lose strength over time. HUASHENG fire retardant polystyrene flame retardant grade-F stands out as a reliable EPS insulation material trusted by builders.

Product Features:

Product introduction

The F-flame retardant grade EPS is not just another insulation board. It’s a fire retardant polystyrene material that has passed UL certification (no. E360952). In the production line, mixing with ordinary EPS is a big no-go—once you do that, the flame resistance of the EPS insulation material will drop fast. This grade follows GB/T10801.1-2002 and GB8624-2012, both key national standards for EPS foam insulation. To achieve reliable B2 performance, the material needs proper aging. Residual blowing agents must escape from the foam body. It’s the same principle whether you’re dealing with expanded polystyrene bead insulation, EPS wall insulation, or even larger polystyrene blocks for construction.

Typical numbers from real production:

15 KG/M³: 20 mm thick, at least one week aging period 20 mm thick, at least two weeks aging period

30 KG/M³: 50 mm thick, at least two weeks of aging 50 mm thick, at least three weeks of aging

Product characteristics

| Specification | Particle size | First expansion ratio | |

| Material F | 301 | 1.0-1.8 | 50-70 |

| 302 | 0.8-1.3 | 45-65 | |

| 303 | 0.6-1.0 | 40-60 | |

| 401 | 0.3-0.8 | 30-50 |

Product Advantages

Application Field

Copyright © Huasheng Qihang (Tianjin) International Trade Co., Ltd. All Rights Reserved