Si ha pedido una cámara de gama alta o una delicada pieza de decoración del hogar recientemente, es probable que haya experimentado ese momento de ansiedad al abrir la caja. Espera que el producto sobreviviera a los golpes y caídas del largo viaje desde el almacén hasta su porche. Para las empresas de comercio electrónico, esto es’ t solo un problema de servicio al cliente; Es una enorme financiera. Las devoluciones debido a daños de envío cuestan a los minoristas miles de millones cada año. Esta es la razón por la que la industria está cambiando rápidamente hacia la espuma REPS, un material de alto rendimiento que está cambiando el juego para el envasado para el express. A diferencia de los materiales tradicionales, REPS La espuma ofrece una combinación única de extrema dureza y increíble ligereza. En este artículo, exploraremos cómo este material innovador, a menudo obtenido de proveedores especializados en perlas REPS, está ayudando a las marcas a proteger sus productos más sensibles al tiempo que reduce sus costos logísticos.

Evolución de los materiales protectores en la era del envío rápido

El negocio de entrega ha cambiado más en los últimos cinco años que en los veinte anteriores. El servicio del mismo día y las ventas en línea en todo el mundo han crecido mucho. Como resultado, una caja podría pasar a través de diez trabajadores’ manos y tres sistemas de cinturón antes de llegar al comprador. La espuma de poliestireno expandido regular (EPS) ha servido bien durante muchos años. Sin embargo, a menudo se pierde la potencia de retención de la forma necesaria para múltiples golpes.

Hoy’ La entrega necesita una sustancia que tome un golpe y se recupera sin romperse. Aquí es donde la espuma REPS personalizada encaja. Los fabricantes han mejorado la perla’ La construcción interna. Hicieron una espuma que resiste mucho mejor que los tipos básicos. Cuando comprobas las necesidades de empaque ocupado para el express, ves que la calidad media ya no funcionará. Las empresas necesitan un material que coincida con los cambios en las rutas de los envíos.

Por qué la resiliencia es el nuevo estándar para los bienes frágiles

En el pasado, si quería más protección, simplemente agregaba más material. Esto resultó en cajas masivas llenas de montañas de plástico, que los clientes odiaban y las compañías de envío cobraban una fortuna. La espuma REPS resuelve esto ofreciendo una absorción de energía superior en un perfil mucho más delgado. No’ t simplemente bloquear un impacto; lo difunde.

Para las empresas que envían artículos tecnológicos, el envasado de espuma de instrumentos de precisión tiene que golpear ciertos “ G-fuerza” niveles. Supongamos que un paquete cae de un metro de altura. Luego, la espuma debe mantener las partes interiores bajo 40G de presión. Dado que la espuma REPS ofrece una construcción más fuerte que la espuma de poliestireno expandido habitual, los diseñadores pueden crear piezas más limpias y más ajustadas. Esto proporciona un 30% más de seguridad. Sin embargo, ocupan un 20% menos de espacio.

La ventaja térmica en la logística global

No se trata solo de caídas. Las condiciones dentro de la caja de transporte también importan. Un envío esperando en una pista en un lugar caliente como Dubai podría alcanzar más de 60 ° C (140 ° F) dentro. Mientras tanto, un avión a 30.000 pies puede sentirse muy frío. Las espumas básicas pueden rigidirse o cambiar de forma en cambios de temperatura tan amplios.

Expertos fabricantes de espuma REPS como HUASHENG han construido sus perlas para mantenerse estables en un amplio rango de calor. Esta característica resulta vital para el envasado de espuma de instrumentos de precisión, como monitores de salud o lentes de vidrio. Incluso una pequeña hinchazón o contracción en el relleno podría conducir a un error de configuración. Al mantener un espacio constante en el interior, la espuma REPS se asegura de que el artículo llegue a usted justo cuando dejó la planta. No importa el clima en el camino.

Reducir costos a través de la ligereza y la ingeniería de precisión

Cada gramo cuenta en el mundo del comercio electrónico. Servicios como FedEx y UPS ahora usan “ Peso dimensional” (DIM) tasas. Le facturan por el espacio que ocupa su caja, no solo su peso real. Si su envoltura agrega demasiado tamaño, termina pagando para mover el espacio vacío.

La belleza de Espuma REPS es su alta relación resistencia-peso. Debido a que el material es tan fuerte, puede usar menos de él para lograr la misma calificación de seguridad. Esto permite a las empresas utilizar cajas externas más pequeñas. En una operación de alto volumen, reducir el tamaño de una caja en solo 2 cm en cada dirección puede ahorrar a una empresa $ 50,000 o más en gastos de envío anuales. Es un caso raro en el que el mejor material realmente termina siendo la opción más barata a largo plazo.

Maximizar el espacio de los contenedores con diseños personalizados

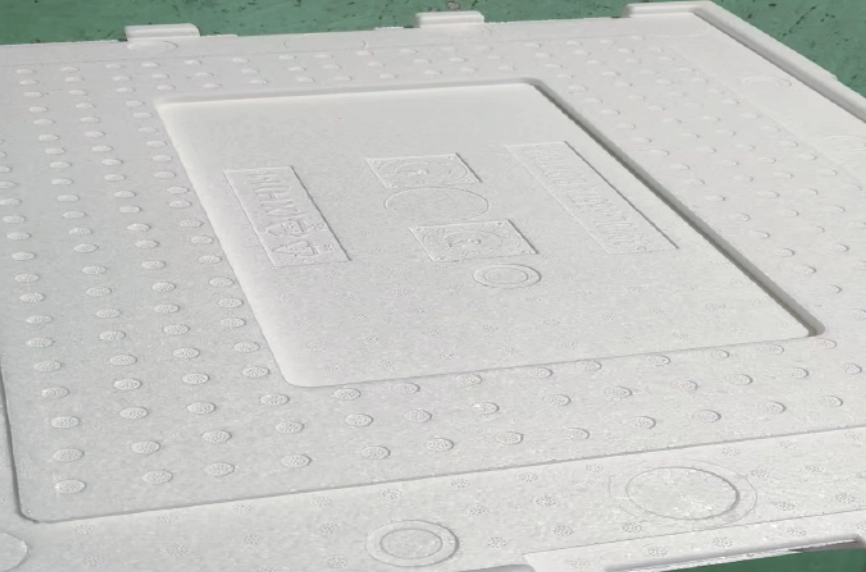

Cuando utiliza espuma REPS personalizada¿Estás’ t simplemente comprar un bloque de plástico; Estás comprando una herramienta de ingeniería de precisión. Los diseñadores profesionales pueden moldear la espuma para ajustarse a los contornos exactos de un producto, eliminando la necesidad de “ rellenos vacíos” como envoltura de burbujas o envasado de cacahuetes.

- Eliminación de residuos: No más materiales de relleno suelto que arruinan al cliente’ Sala de estar.

- Reducción del trabajo: Embalaje se convierte en 5 segundos “ soltar y hacer clic” proceso en lugar de una tarea de envoltura de 2 minutos.

- Peso DIM más bajoPaquetes más pequeños y densos que cuestan menos volar y transportar por todo el país.

- RepetibilidadCada caja está empaquetada exactamente de la misma manera, reduciendo el error humano que conduce a daños.

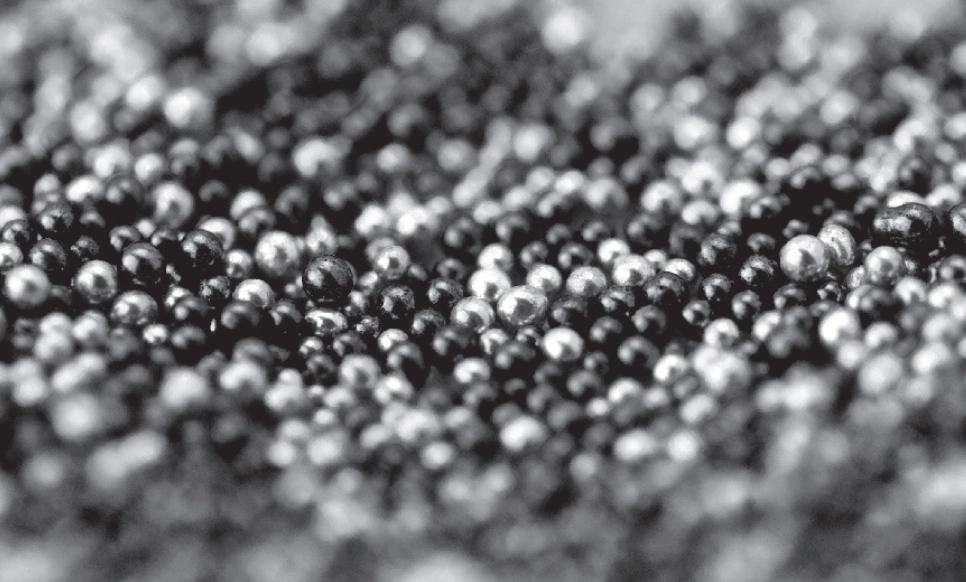

El papel de los proveedores de perlas REPS en la consistencia del material

La calidad de la pieza de espuma final está dictada por las materias primas. Si las perlas tienen una densidad o un contenido de humedad inconsistentes, la espuma resultante tendrá puntos débiles. Es por eso que elegir los proveedores de perlas REPS adecuados es la base de una cadena de suministro fiable. Las perlas de alta calidad aseguran que el “ fusión” durante el proceso de moldeo es perfecto.

En HUASHENGNos tomamos en serio esta coherencia. Entendemos que para el envasado para el express, una tasa de fallo del 1% en la espuma es un 1% demasiado. Controlando el proceso de preexpansión y el tiempo de envejecimiento de las perlas, producimos espuma REPS que tiene una estructura celular uniforme. Esta uniformidad es lo que permite la amortiguación predecible y de alto rendimiento en la que confían las marcas electrónicas de primer nivel.

El cambio de sostenibilidad: por qué REPS es la opción más verde

Existe un malentendido común de que toda la espuma plástica es una pesadilla ambiental. Si bien es cierto que las espumas antiguas eran difíciles de reciclar, la espuma de poliestireno expandido moderna y sus derivados como REPS son en realidad 100% reciclables. Debido a que están hechos de 98% aire, tienen una huella de carbono sorprendentemente baja cuando se considera la energía necesaria para producirlos y transportarlos en comparación con el cartón pesado o la pasta moldeada.

Además, “ resistencia” de espuma REPS significa que a menudo puede reutilizarse múltiples veces. En un sistema logístico de bucle cerrado, como el envío de piezas entre una fábrica y una planta de montaje, un único inserto de espuma REPS personalizado puede sobrevivir a 50 o más viajes. Esta longevidad reduce significativamente la cantidad total de residuos generados por el sector manufacturero.

El reciclaje y la economía circular

Muchos fabricantes de espuma REPS ahora están integrando “ post-industrial” contenido reciclado de nuevo en su producción de perlas. Esto significa que la chatarra del piso de la fábrica es’ t desechado; se molió, fundió y volvió a convertirse en nuevas perlas de espuma REPS.

Para el consumidor final, el proceso también se hace más fácil. Muchas ciudades ahora tienen centros dedicados al reciclaje de plásticos #6. Debido a que la espuma REPS es tan ligera, no’ t tomar mucho combustible para transportarlo a una instalación de reciclaje donde puede ser densificado y convertido en nuevos productos como marcos de imágenes o moldeo de corona. Al elegir un socio ecológico como HUASHENG, las marcas pueden cumplir sus objetivos ESG (Medioambiental, Social y Gobernanza) sin sacrificar la seguridad de sus productos.

Reducir el costo del carbono de los daños

El más “ no sostenible” Lo que una empresa puede hacer es enviar un producto que se rompe. Si una computadora portátil de 1.000 dólares es destruida en tránsito debido a un embalaje deficiente, el costo del carbono de ese incidente es masivo. Tienes el carbono de la fabricación original, el envío de la unidad rota, el envío de la devolución y la fabricación del reemplazo.

Al usar espuma REPS de alto rendimiento, las empresas evitan esto “ doble envío” ciclo. Un embalaje fiable para la estrategia express es, en sí mismo, una estrategia de sostenibilidad. Cuando lo consigues bien la primera vez, ahorras energía, combustible y materiales. Es por eso que muchos proveedores de perlas REPS ahora se centran en “ tamaño derecho” soluciones de envasado que priorizan la protección como la forma principal de reducir una empresa de comercio electrónico; Impacto ambiental general.

Por qué HUASHENG es la elección profesional para las soluciones REPS

Con tantos fabricantes de espuma REPS en el mercado, ¿por qué las marcas globales eligen HUASHENG? Se reduce a nuestra profunda comprensión del material’ Física S. No’ t sólo vender espuma; Ofrecemos una asociación de ingeniería de servicio completo. Ya sea que necesite el envasado de espuma de instrumentos de precisión o insertos de comercio electrónico de alto volumen, tenemos la maquinaria y la experiencia para entregar.

Nuestra instalación está equipada con máquinas de moldeo de forma de última generación que permiten geometrías complejas que otras tiendas simplemente pueden ’ t manija. Trabajamos estrechamente con nuestros clientes para probar prototipos y asegurarnos de que la densidad de la espuma REPS se ajuste perfectamente al peso y la fragilidad de su producto específico. Creemos que cada paquete es un punto de contacto de la marca, y queremos que ese punto de contacto sea perfecto.

En el mundo de rápido movimiento del comercio electrónico, usted puede’ t esperar seis meses para un nuevo diseño de embalaje. Nos enorgullecemos de nuestra capacidad de pasar de un dibujo CAD a un prototipo físico personalizado de espuma REPS en un tiempo récord. Nuestro equipo de ingeniería puede simular pruebas de caída y tensiones de vibración incluso antes de cortar el primer molde.

Este enfoque basado en datos es lo que nos separa de los proveedores estándar de espuma de poliestireno expandido. Damos a nuestros clientes los números que necesitan para tener confianza. Cuando sepa exactamente cómo funcionará su espuma REPS a -20 ° C o después de una caída de 2 metros, puede dormir mejor por la noche. Te invitamos a explorar nuestro soluciones REPS personalizadas y vea cómo podemos ayudarlo a agilizar su proceso de cumplimiento.

Conclusión

El mundo de las ventas en línea se hará cada vez más difícil y apremiante. A medida que los precios de entrega suben y los compradores quieren que los artículos lleguen sin defectos, las cosas que usamos para proteger los productos se vuelven aún más clave. Espuma REPS destaca por las empresas que equilibran la guardia, el ahorro de dinero y el cuidado de la tierra. Pasar a una solución de espuma REPS superior hace más que ahorrar una caja. Protege su marca’ Nombre y ganancias. Si está listo para ver la diferencia que la ingeniería profesional puede hacer, póngase en contacto con HUASHENG hoy en info@r-eps.comDeje que nuestro equipo de expertos le mostre por qué somos los principales fabricantes de espuma REPS para la era moderna del comercio global.