The path of Expanded Polystyrene (EPS) has undergone a profound change. Previously regarded as only an ordinary plastic designed for simple safeguarding, it has evolved into a sophisticated substance guided by precise molecular control and a broad range of practical uses. EPS is no longer defined simply by its whiteness or volume, but by its capacity to solve complex industrial paradoxes.

We are currently witnessing a dual-sector transformation where this material is simultaneously resolving the “lightweight versus protection” conflict in global logistics and the “energy efficiency versus fire safety” challenge in modern green building. This article examines the technical evolution of EPS, analyzing how density modification, graphite integration, and the emerging circular economy of Recycled EPS (REPS) are rewriting the standards of performance.

Why is Precision Engineering Crucial for Modern Packaging?

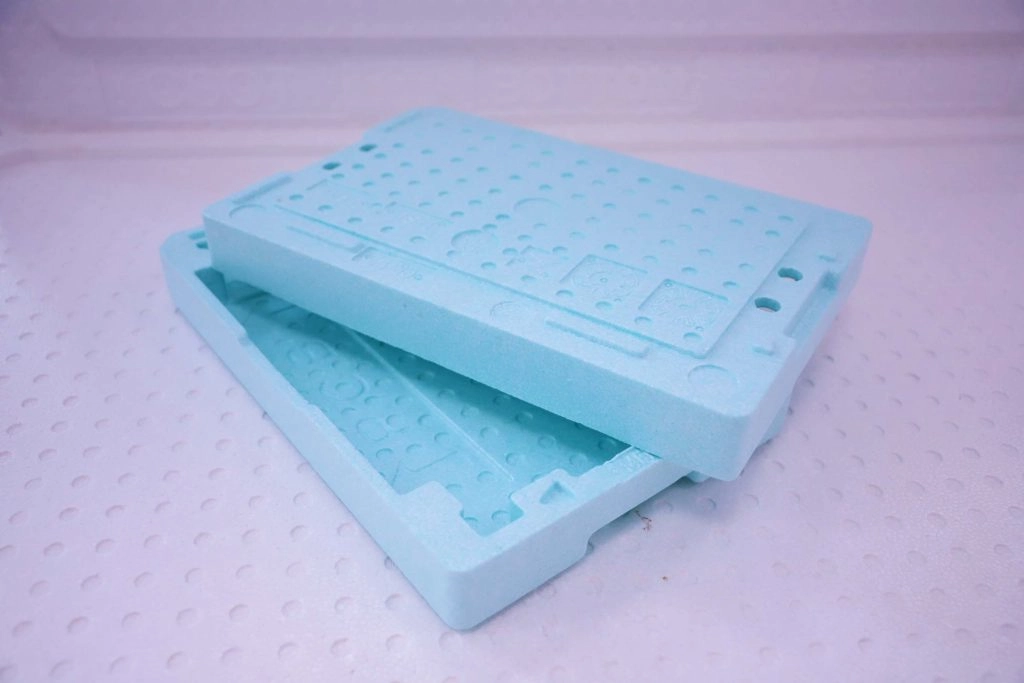

With supply networks stretching farther and the worth of transported goods rising steadily, the packaging material needs to function as an active load-bearing element instead of mere padding, which calls for a shift from ordinary molding methods to detailed design.

Can Low Density Achieve High Impact Resistance?

The core engineering challenge in packaging is maximizing shock absorption while minimizing tare weight. The answer lies in the manipulation of bead geometry and expansion ratios. Through tight control of bead sizes between 0.3 mm and 1.6 mm and adjusting the expansion ratios between 35 and 100 times, specialists can adjust the compressive strength of the finished structure accurately.

Consider the requirements of high-throughput manufacturing. “Rapid Prototyping” materials are engineered specifically for automatic molding machines. These materials are characterized by short curing times and fast demolding capabilities, which can increase comprehensive molding efficiency by over 50% while maintaining the structural integrity required for precision instruments.

Conversely, for large-scale applications such as ceramic transport or paneling, “Ultra-Light” solutions (P-Material) challenge the assumption that density equates to toughness. Through advanced polymerization, these materials achieve high foaming rates (up to 100 times expansion) while retaining sufficient mechanical fusion to prevent fragmentation under vibration. This capability allows you to significantly reduce logistics weight without compromising the safety factor of the cargo.

How Do Customized Formulations Adapt to Complex Geometries?

As product designs become more intricate, the dimensional stability of the packaging medium becomes paramount. A common failure point in standard EPS is post-molding shrinkage, which compromises the fit between the packaging and the product, leading to vibration damage. Advanced formulations address this by optimizing the curing cycle and steam penetration rates.

For special applications such as liquid crystal panels or health equipment, uniform bead sizes no longer work. The selection of particular bead measurements ensures complete filling of the mold cavity along with uniform fusion of particles. Such tailored selection makes the packaging serve as an effective exterior framework, dissipating motion energy via controlled bending instead of passing that force onward to vulnerable contents.

How Are Advanced Formulations Revolutionizing Building Insulation?

Packaging emphasizes the management of kinetic energy, but construction requires strong control over thermal energy. The current building envelope requires materials that provide maximum insulation with minimal thickness, while following strict fire safety regulations.

Can Graphite Infusion Boost Thermal Resistance?

Standard EPS is a formidable insulator, but it has physical limits regarding radiant heat transfer. The industry has surmounted this barrier through the introduction of infrared absorbers, specifically natural flake graphite, into the polymer matrix via extrusion processes. These graphite particles act as microscopic mirrors, absorbing and reflecting radiant energy within the foam beads.

The thermodynamic impact is quantifiable and significant. Advanced graphite grade–S EPS foam achieves a thermal conductivity of less than 0.033 W/(m·K). Relative to the usual 0.039 W/(m·K) found in ordinary EPS, such advancement yields over 20% better resistance to heat transfer. In low-energy house designs and efficiency-saving structures, thinner layers meet required U-values, thereby increasing interior living area while preserving overall thermal savings. Moreover, these advanced materials maintain strong load-bearing capacity together with B1-level fire resistance, combining lasting structural reliability with superior heat management.

Is It Possible to Balance Flame Retardancy with Eco-Safety?

Serious conflict arises between requirements for the feature of fire resistance and the avoidance of lasting ecological harm. In earlier times, HBCD served as the typical additive for slowing flames, but concerns over its long-term harm to nature prompted a worldwide phase-out. Current accepted practice across the sector relies on alternatives lacking HBCD that satisfy strict European chemical regulations, including REACH and ROHS.

However, chemical compliance must not degrade performance. To meet construction requirements, these eco-friendly formulations must still achieve an Oxygen Index (OI) of more than 30 or 32. Achieving this requires a disciplined manufacturing process, specifically regarding the “aging period.” You cannot rush the post-molding phase, as molded products require a specific duration (often weeks, depending on density) to allow residual blowing agents to escape. Only then does the material achieve its full B1 or B2 fire-retardant potential and dimensional stability.

Who is HUASHENG, and what is its role in the EPS manufacturing?

HUASHENG is not merely a manufacturer, but a pioneer driving a global material revolution. By leveraging a digital twin laboratory and a massive 300,000-ton recycling capacity, we turn basic polystyrene particles into strong tools for lasting practices.

HUASHENG has moved beyond the simple production of foam and is engineering the future of “technology for good.” Our facility includes the world’s first smart production line for polystyrene using 100% recycled raw materials, achieving a waste recycling rate of over 95%. Whether you require high-performance insulation or shock-resistant packaging, our commitment ensures every solution meets rigorous global standards while actively reducing the environmental burden.

Can the Industry Achieve a True Circular Economy with EPS?

The final frontier for EPS is the transition from a linear “make-use-dispose” model to a circular ecosystem. This is no longer aspirational, but a technical reality driven by advancements in recycling technologies that restore polymer integrity.

Does Recycled Content Compromise Strength?

A prevailing misconception is that recycled material inherently suffers from performance degradation. This is largely true for chemical recycling methods, but modern physical modification processes have changed the equation. By utilizing physical masterbatch processes, manufacturers can reduce waste emissions and energy consumption by over 20% compared to traditional chemical methods.

The result is Extrusión REPS personalizado that retain exceptional toughness and impact resistance. Through innovations like molecular chain directional weaving technology, the compressive strength of REPS can be increased by 40%, allowing it to rival virgin materials. These materials comply with international PS recycling category 6 standards and are qualified for high-end export projects, including protective packaging for electronics, liquid crystal panels, and new energy automotive parts.

What Are the Economic Implications of Closed-Loop Systems?

Sustainability is increasingly becoming a competitive economic advantage. Lasting practices now provide clear business gains. Producing reused substances closer to use points cuts reliance on imported fresh supplies, protecting against sharp changes in raw material costs.

Furthermore, the environmental ROI is substantial. Implementing a closed-loop system can reduce the carbon footprint of EPS production by up to 72% compared to virgin material. As regulations tighten, the ability to provide “Material Passports” via blockchain-enabled tracking ensures that green claims are verifiable, safeguarding your projects against compliance risks and enhancing Environmental, Social, and Governance (ESG) scores.

Conclusión

EPS has transcended its origins to become a cornerstone of modern material science. It is no longer just about insulation or packaging, but about the precise application of molecular engineering to solve systemic industrial challenges. From heat management in graphite-enhanced foam to strong reuse in high-strength REPS, the material offers a synergy of performance and sustainability. For specialists in the field, selecting this material becomes a planned technical choice—one that shapes project efficiency, safety, and environmental legacy.

Preguntas frecuentes

Q: How does the thermal conductivity of graphite-modified EPS compare to standard EPS?

A: Graphite-modified EPS includes infrared blockers and natural flake graphite to handle radiated heat, reaching thermal conductivity below 0.033 W/(m·K). This shows more than 20% better performance than standard EPS, offering clear advantages for low-energy houses and efficiency-driven structures.

Q: Can recycled EPS (REPS) be used for high-precision packaging without sacrificing quality?

A: Yes, modern REPS derived from physical modification processes retain moderate toughness and strength, making them suitable for demanding packaging projects. Through technologies like molecular chain directional weaving, the compressive strength is comparable to virgin materials, allowing its use in packaging for electronics, liquid crystal panels, and automotive parts.

Q: What is the significance of the “aging period” in the production of flame-retardant EPS?

A: The aging period is critical for allowing residual foaming agents to escape from the molded product, which ensures the material achieves its optimal B2 or B1 flame-retardant performance. Based on density and thickness, this stage usually lasts one to three weeks—rushing it risks weaker shape stability and lower fire safety ratings.