Los materiales de espuma personalizados proporcionan rasgos mecánicos exactos, capacidades de bloqueo térmico y soporte estructural que las espumas ordinarias simplemente no pueden lograr. Estas características son vitales para sectores desafiantes como la automoción, la electrónica, la atención médica y la construcción de edificios. Al ajustar la densidad, la resistencia, los niveles de aislamiento y los aditivos especiales, los productos de espuma a medida mejoran el ajuste, la vida útil, los estándares de seguridad y los resultados ecológicos. Trabajar estrechamente con un productor cualificado trae una creación precisa de muestras, una producción constante a gran escala, menos chatarra y flujos de suministro más suaves. Los tipos de espuma de alta calidad y especializados ayudan a proyectos exigentes, características únicas del producto y exigencias legales, al tiempo que cumplen los objetivos de rendimiento con el cuidado del medio ambiente.

¿Qué hace que los materiales de espuma personalizados sean críticos para el rendimiento de su producto?

Por qué la espuma disponible a menudo no satisface las demandas específicas de la industria

Los productos de espuma regulares comprados directamente de stock rara vez proporcionan la resistencia precisa y las cualidades relacionadas con el calor que requieren campos particulares. Las espumas comunes carecen del peso necesario por volumen, capacidad de rebote o firmeza para ciertas tareas. Por ejemplo, en la fabricación de automóviles o envases médicos, la falta de rebote adecuado puede causar flexión o daño cuando aparece presión. Además, los materiales habituales pueden no seguir reglas estrictas o límites verdes en algunos mercados. Áreas controladas como electrónica y hospitales exigen el pleno respeto de normas como RoHS, REACH o aprobaciones de la FDA.

Los peligros asociados a piezas de espuma mal emparejadas o débiles siguen siendo graves. El mal ajuste o los resultados bajos pueden desencadenar la avaría del producto, gastos más altos o problemas de seguridad. Por otro lado, la espuma hecha a medida garantiza que los límites de diseño reciban un respeto exacto, evitando retrasos, devoluciones o daños a la empresa. su reputación.

Cómo las soluciones de espuma a medida abordan los desafíos funcionales y estructurales

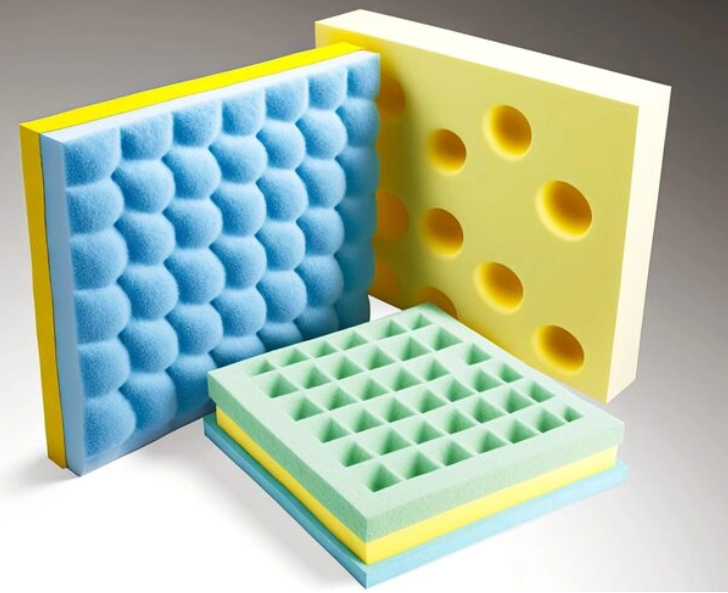

La producción de espuma personalizada permite a los ingenieros ajustar los valores de resistencia a necesidades muy estrictas. Dicho ajuste permite elecciones claras para la resistencia a la presión, la protección contra el calor y la flexibilidad. Ya sea que el objetivo implique soportes ligeros para baterías de automóviles eléctricos o cajas de temperatura constante para medicamentos biológicos, la espuma a medida ofrece funcionalidad específica.

Los productos pueden recibir ingeniería para la reducción del sonido, la absorción de golpes o la resistencia a los productos químicos. Como ejemplo, Lanzhou HUASHENG Materiales REPS encuentran un amplio uso en el empaquetado de pantallas LCD, artículos médicos y dispositivos 3C debido a su protección contra golpes mejorada y estructura estable. Las mediciones exactas aseguran un ajuste suave en las líneas de montaje. Esta precisión es muy importante en sistemas automáticos donde incluso pequeñas diferencias pueden conducir a tiempo de inactividad.

¿Cómo seleccionar el material de espuma personalizado adecuado para su aplicación?

¿Qué parámetros técnicos clave debe evaluar primero?

La elección de espuma personalizada comienza identificando los parámetros técnicos principales. La densidad y la estructura celular determinan cuánta carga soporta el material y lo bien que bloquea el calor. En proyectos de construcción que ahorran calor como las casas pasivas, materiales como el poliestireno grafito S-32 proporcionan valores de transferencia de calor a o por debajo de 0,032 W/m·K, mejorando el aislamiento en más de un 25% en comparación con el EPS tradicional.

Las tasas de transferencia de calor afectan al rendimiento en entornos sensibles a los cambios de temperatura, lo que es especialmente importante para la logística de la cadena de frío o las envolturas de edificios. La resistencia al fuego y las emisiones de COV son importantes para campos controlados como los vehículos o la construcción. HUASHENG suministra tipos de EPS ignífugos clasificados B1, incluidos FS y FSH que cumplen con los estándares GB8624 y funcionan bien para placas de aislamiento de nivel superior.

Por qué la colaboración con un fabricante experto mejora la optimización de materiales

Trabajo en equipo estrecho con un fabricante como Lanzhou HUASHENG convierte las ideas de diseño en productos reales y listos para la fábrica. El personal cualificado ayuda a cambiar los dibujos CAD en muestras de espuma con límites estrictos. Sus capacidades incluyen ingeniería de tamaño de partícula personalizada, donde el tamaño de partícula estándar varía de aproximadamente 0,8 a 1,2 mm, y la producción personalizada también se puede llevar a cabo de acuerdo con proyectos específicos que permiten el ajuste fino estructural.

Además, los expertos en materiales guían la elección de aditivos o capas superficiales para una vida útil más larga. Es evidente en las formulaciones REPS desarrolladas utilizando tecnología de estructura de poros nanocerrados que aumentaron la resistencia a la compresión de los materiales REPS en un 40%, superando con mucho los niveles avanzados internacionales. Un socio como HUASHENG ofrece no solo capacidad de producción, sino también un profundo soporte técnico adaptado a sus especificaciones.

¿Pueden los materiales de espuma personalizados cumplir con los objetivos de sostenibilidad y cumplimiento?

Cómo las regulaciones ambientales influyen en las elecciones de composición de materiales

Los mandatos ambientales ahora guían fuertemente la elección de materiales en muchos campos. El cumplimiento de las normas RoHS, REACH y similares requiere una selección cuidadosa de ingredientes. Los artículos REPS de HUASHENG contienen informes de prueba REACH y RoHS, lo que indica que se adaptan al comercio mundial.

Las espumas sostenibles reducen las cantidades totales de emisiones mientras mantienen sólidas métricas de rendimiento. El uso de materias primas reutilizadas por HUASHENG en la producción de REPS crea una huella de carbono de solo 719,14 kg de CO ₂ eq por tonelada, proporcionando beneficios tanto ambientales como económicos.

¿Qué papel desempeñan las alternativas ecológicas en la ingeniería moderna de espuma?

Elecciones como Extrusión REPS personalizado traer respuestas reciclables y de baja emisión. A diferencia del EPS tradicional, que es difícil de reciclar, el REPS cumple con la categoría 6 internacional de reciclaje de PS, se puede usar para proyectos de exportación y reciclarse internamente para re-granulación o tratamiento degradado.

Estas opciones se integran en usos difíciles como el transporte médico en frío y el embalaje de dispositivos. Los materiales mantienen la integridad mecánica mientras coinciden con las etiquetas verdes. La aprobación GRS de HUASHENG destaca su promesa de producción de ciclo completo.

¿Cómo la personalización mejora la eficiencia en toda su cadena de suministro?

¿De qué manera la fabricación de precisión reduce los residuos y los sobrecostes?

Las dimensiones de la espuma personalizadas eliminan el recorte excesivo durante el montaje final. Las dimensiones personalizadas minimizan el recorte durante el montaje, reduciendo el tiempo de trabajo y la pérdida de material, y logrando operaciones más delgadas con tasas de defectos más bajas.

La calidad del lote constante corta rechazos y retornos de compradores posteriores. Gracias a los sistemas de planta inteligentes de HUASHENG, las perlas de espuma muestran una alta uniformidad y patrones de crecimiento esperados, que son críticos en las líneas de moldeo automático en electrónica o fabricación de automóviles.

Por qué es importante la escalabilidad al integrar espuma personalizada en líneas de producción

Las soluciones de espuma personalizadas diseñadas para la modularidad aceleran los nuevos ciclos de desarrollo de productos. Las piezas modulares de espuma apoyan los principios de fabricación magra. Por ejemplo, las piezas en forma de EPS de fuerte impacto en algunos proyectos reducen el peso de la batería en un 37% y ahorran $ 230,000 al año por vehículo, lo que demuestra claras ganancias a gran escala.

Las estrategias de entrega justo a tiempo se vuelven viables con socios confiables de fabricación personalizada. A través de los servicios colaborativos de proceso completo de Huasheng, que abarcan diseño, muestreo, producción, logística, la cadena de suministro de espuma se sincroniza con los horarios de producción OEM.

¿Dónde encajan los grados avanzados de espuma en aplicaciones de alta especificación?

¿Cuándo Debería Considerar Formulaciones Especiales Sobre Espumas Convencionales?

Cuando las aplicaciones exigen alta resistencia al calor, retardancia al fuego o disipación estática, los grados especializados son esenciales. Las aplicaciones que requieren blindaje térmico o disipación estática se benefician de grados de ingeniería como Grado especial (material de llenado) – GLa serie G incluye variantes antiestáticas con impedancia superficial de 10 ⁹–10 Ω, crítico para envases electrónicos.

Para aislamiento aeroespacial o paneles de casa pasiva, las espumas de grafito S-32 proporcionan un borde térmico significativo con una conductividad térmica inferior a 0,032W/M.K, superando el EPS estándar en más del 25%.

¿Cómo pueden los grados especializados mejorar la diferenciación de productos en mercados competitivos?

Los grados avanzados permiten a los fabricantes ofrecer características de rendimiento que diferencian a los productos. Las propiedades únicas del material le permiten crear productos más ligeros, seguros o duraderos que los competidores. Por ejemplo, los sustratos de escultura ArtFrame utilizan partículas de EPS teñidas personalizadas (tamaño de partícula 2-4 mm), lo que permite ganancias de estabilidad estructural del 70% al tiempo que reduce el tiempo de instalación de la exposición a la mitad.

Los tratamientos en relieve o superficiales personalizados agregan valor a la marca mientras mantienen la función técnica. Estos elementos visuales y táctiles son particularmente valiosos en electrónica de consumo y envases minoristas donde la apariencia influye en la compra.

Preguntas frecuentes

P: ¿Puedo solicitar una pequeña producción de espuma personalizada antes de la fabricación a escala completa?

R: Sí, casi todos los fabricantes de espuma personalizados ofrecen ejecuciones de muestra para que los rasgos de ajuste y trabajo reciban pruebas antes de que comiencen los grandes pedidos.

P: ¿Son las espumas personalizadas adecuadas para aplicaciones al aire libre con exposición a los rayos UV y la humedad?

R: Ciertamente, las mezclas especiales pueden agregar bloqueadores UV y capas impermeables construidas exactamente para una potencia duradera externa.

P: ¿Cuánto tiempo suele tomar desarrollar una solución de espuma personalizada desde el concepto hasta la entrega?

R: Los plazos difieren según la profundidad del proyecto pero generalmente caen entre 2-6 semanas. Este período cubre las conversaciones de diseño, la fabricación de muestras, los controles y la preparación de la producción final.