El embalaje de poliestireno expandido (EPS) es un material de espuma muy ligero pero fuerte. A la gente le encanta porque da un gran amortiguamiento, mantiene las cosas calientes o frías y cuesta poco dinero. Lo ves mucho cuando envías alimentos que pueden deteriorarse rápidamente, electrónica y artículos rompibles. Se puede moldear fácilmente en formas personalizadas. Lo mejor de todo, el EPS se puede reciclar, por lo que ayuda a las empresas a ser más verdes.

Comprender el poliestireno expandido (EPS) y su proceso de fabricación

¿Qué es el embalaje de poliestireno expandido?

El embalaje de poliestireno expandido es súper común en fábricas y tiendas. Tiene características especiales y ahorra dinero. El poliestireno expandido (EPS) es una espuma ligera y dura. Los trabajadores lo hacen de pequeñas perlas redondas de poliestireno. Esas perlas provienen de unir partes de estireno.

Dentro de EPS, casi todo es aire. Aproximadamente el 98% es solo aire atrapado en minúsculas células cerradas. Esto lo hace ligero pero todavía duro. Muchas industrias lo eligen porque es barato y funciona bien. En el embalaje, protege las cosas que se agitan fácilmente. Toma en choques tan bien que los teléfonos, televisores y herramientas médicas llegan a salvo.

Cómo se fabrica el EPS

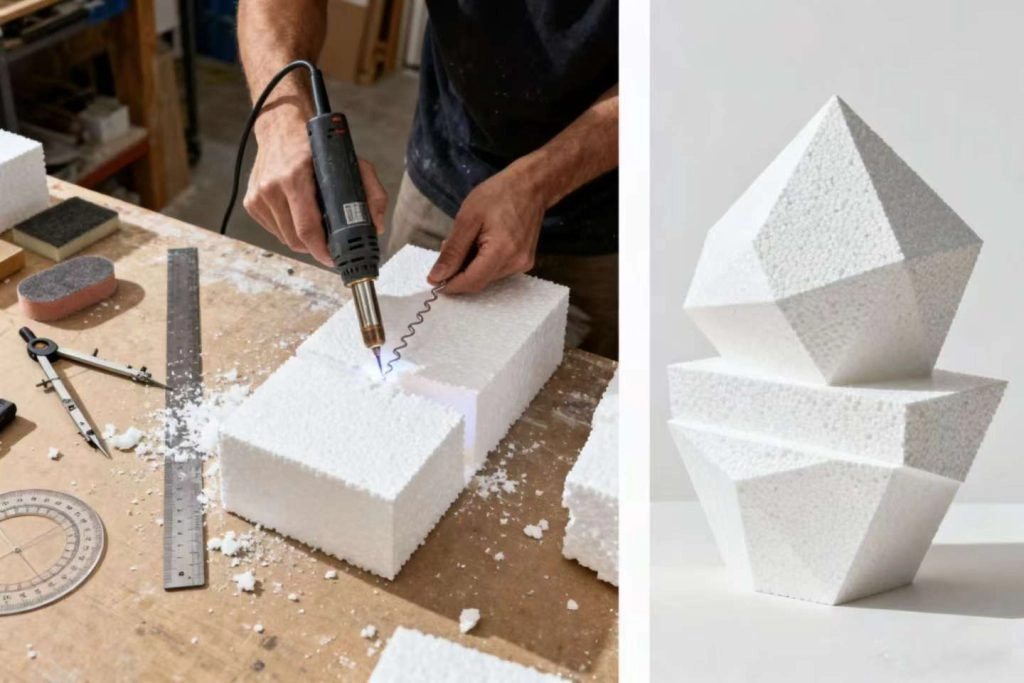

Hacer EPS requiere varios pasos claros. En primer lugar, los trabajadores colocaron las pequeñas perlas en una máquina grande llamada pre-expandidor. El vapor y la presión hacen que las perlas crezcan. ¡Pueden ser 50 veces más grandes! Las perlas se vuelven suaves, se pegan juntas y atrapan el aire dentro.

Después de eso, la gente deja que las grandes perlas descansen por un tiempo. Este tiempo de descanso, llamado envejecimiento, los ayuda a ser estables y uniformes.

A continuación viene la parte de moldeo. Los trabajadores pusieron las perlas descansadas en formas metálicas. El vapor caliente entra de nuevo. Las perlas se derriten un poco y se pegan perfectamente. Cuando se enfría, obtiene un bloque fuerte o una forma especial. Por último, los trabajadores lo cortan y limpian para que esté listo para usar.

Cada paso tiene controles. La gente prueba la densidad, la fuerza y el tamaño. De esta manera, cada pieza de EPS funciona muy bien.

Características de rendimiento clave de EPS Packaging

Estructura ligera reduce los costos logísticos

El EPS no pesa casi nada. Sin embargo, se mantiene fuerte. Debido a que es tan ligero, el envío se vuelve más barato. Los camiones usan menos combustible. Los trabajadores levantan las cajas más fácilmente. Las empresas ahorran dinero real todos los días.

Capacidades de aislamiento térmico superiores

El EPS mantiene el calor o el frío en el interior muy bien. Los pequeños bolsillos de aire detienen los cambios de temperatura. Es por eso que el pescado, la fruta y la medicina permanecen frescos más tiempo. Incluso en días calientes o congelados, la temperatura interna apenas se mueve.

Excelentes propiedades de amortiguación y amortiguación

Cuando algo golpea una caja de EPS, la espuma toma el golpe. Se dobla un poco y luego vuelve a su forma normal. Las piezas frágiles de vidrio, cerámica o computadora casi nunca se rompen. Es por eso que las tiendas confian tanto en el empaquetado de poliestireno expandido.

Alta flexibilidad de diseño para soluciones de embalaje personalizadas

Puedes transformar EPS en casi cualquier cosa. ¿Necesitas un ajuste perfecto para una lámpara de forma extraña? No hay problema. ¿Necesitas ranuras pequeñas para muchas piezas pequeñas? Fácil. Las empresas aman esta libertad. Obtienen exactamente lo que su producto necesita.

Eficiencia de costes en la producción en masa

Cuando necesitas miles de paquetes, EPS gana en el precio. Las perlas crudas cuestan poco. Las máquinas utilizan poca energía. En comparación con la pasta de papel u otras espumas, EPS es generalmente la opción más barata para grandes pedidos.

Reciclabilidad y eficiencia de los materiales

EPS no tiene que terminar en la basura. La gente puede limpiarlo, romperlo en pedazos pequeños y hacer cosas nuevas. Algunas empresas convierten el viejo EPS en bancos de parque o cajas nuevas. Usarlo una y otra vez reduce mucho los residuos.

Aplicaciones principales de EPS en la industria del envasado

Existe una amplia gama de aplicaciones para EPS, como la logística de la cadena de frío, el campo de la construcción, la industria alimentaria, los materiales de construcción decorativos, la protección del instrumento preciso, etc.

Embalaje controlado por temperatura para bienes perecederos

El pescado, la carne y las verduras frescas permanecen bien más tiempo dentro de las cajas de EPS. Las paredes gruesas mantienen el frío dentro. La humedad no puede entrar fácilmente. Los agricultores y supermercados recogen EPS todos los días por esta razón.

Embalaje protector para electrónica e instrumentos de precisión

Teléfonos, computadoras portátiles y grandes televisores viajan por el mundo dentro de EPS. La espuma mantiene todo apretado para que nada se mueva. También detiene el daño de la electricidad estática.

HUASHENG producto destacado: El Caja de embalaje de instrumentos de precisión ofrece una protección perfecta contra choques. Se adapta perfectamente a la electrónica delicada.

Protección de artículos frágiles en electrodomésticos y logística de cerámica

Placas, jarrones y hermosas lámparas se rompen fácilmente. Las esquinas de EPS y las paredes interiores suaves detienen las grietas. Incluso si la caja cae, el artículo generalmente permanece seguro.

Destacados del producto HUASHENG: Grado extra ligero - P (Caja de embalaje de lámpara de cerámica) Es súper ligero. Protege las lámparas perfectamente mientras mantiene el peso del envío bajo.

Necesidades de transporte médico y farmacéutico

Las vacunas y la sangre necesitan temperaturas exactas. Las cajas médicas de EPS mantienen todo estable durante muchas horas o incluso días. Los médicos y las empresas farmacéuticas confían en el empaquetado de poliestireno expandido para los artículos que salvan vidas.

Consideraciones ambientales en el uso de EPS

Reutilizabilidad y potencial de reciclaje en ciclo cerrado

El viejo EPS puede tener una segunda vida. La gente lo recoge, lo lava y lo mole. Entonces nuevas cajas o aislamiento del edificio vienen del mismo material. Este círculo ahorra árboles, aceite y espacio en vertederos.

Reducción de la huella de carbono de las emisiones de transporte

Debido a que el EPS es ligero, los camiones queman menos diésel. Se necesitan menos camiones. Esto significa menos humo en el aire. Durante todo el año, los ahorros son enormes.

Eficiencia de recursos en comparación con materiales alternativos

EPS utiliza muy poco plástico para hacer un gran trabajo. Algunos paquetes de papel necesitan muchos árboles y mucha agua para hacer. El EPS necesita mucho menos material de la naturaleza para proteger el mismo producto.

Ventajas estratégicas del uso de las soluciones EPS de HUASHENG en envases industriales

Soporte de ingeniería específico del producto

HUASHENG ayuda a los clientes desde la primera idea hasta la caja final. Hacen muestras rápidas. Cambian el diseño hasta que sea perfecto. Menos material se desperdicia y el precio se mantiene bajo.

Cumplimiento de la industria y garantía de calidad

Cada producto HUASHENG cumple con reglas mundiales estrictas. Los trabajadores revisan cada lote. La densidad, la fuerza y el tamaño siempre son exactamente correctos. Los clientes nunca se preocupan por la seguridad o la calidad.

Preguntas frecuentes

P: ¿Es el embalaje de poliestireno expandido adecuado para electrónica de alto valor?

R: ¡Sí! Su gran absorción de golpes mantiene las costosas placas de circuitos y herramientas médicas seguras en viajes largos.

P: ¿Cómo garantiza HUASHENG la sostenibilidad de sus productos EPS?

R: HUASHENG utiliza grados totalmente reciclables. Las cajas antiguas se vuelven nuevas una y otra vez. Esto ayuda a las empresas a mantenerse verdes y ahorrar dinero.

P: ¿Se pueden personalizar las soluciones de envasado EPS de HUASHENG para artículos de forma irregular?

R: Por supuesto. HUASHENG hace moldes perfectos para formas extrañas como lámparas de cerámica o piezas de máquina extrañas. Todo se mantiene firme y seguro dentro.