En el esfuerzo por crear edificios verdes y de ahorro energético, HVAC Los sistemas (calefacción, ventilación y aire acondicionado) desempeñan un papel importante. Los conductos, una parte clave de estos sistemas, influyen en lo bien que se utiliza la energía. El uso de moldeo EPS (Poliestireno Expandido) para conductos HVAC es una solución inteligente. Ahorra energía y resuelve problemas comunes con el aislamiento y la instalación.

El papel de los sistemas de conductos HVAC en el uso de energía de edificios

Los conductos de HVAC actúan como el sistema de suministro de aire de un edificio. Lleva aire caliente o enfriado a cada habitación. Pero los conductos mal construidos pueden desperdiciar mucha energía.

Por qué el aislamiento térmico es importante en los sistemas HVAC

El aislamiento impide que el calor escape o entre en los conductos. Sin ella, se pierde energía, especialmente en lugares como atados o sótanos. Un buen aislamiento mantiene el aire a la temperatura adecuada. Esto ayuda a que los sistemas HVAC funcionen sin problemas. Evita el trabajo adicional para corregir los cambios de temperatura.

Causas comunes del desperdicio de energía en los conductos tradicionales

Los conductos metálicos a menudo tienen sellos sueltos o fugas térmicas. Estos problemas causan condensación o pérdida de calor. Esto hace que los sistemas HVAC trabajen más duro. El aislamiento tradicional, como la fibra de vidrio, puede desgastarse. Puede absorber agua, lo que reduce su eficacia. Esto aumenta los costos energéticos con el tiempo.

¿Qué es el moldeo EPS y cómo funciona en sistemas HVAC?

El moldeo de EPS está ganando popularidad para la fabricación de piezas de conductos aislados. Sus excelentes propiedades térmicas y su diseño flexible lo convierten en la mejor opción.

Características de Poliestireno Expandido (EPS)

EPS es una espuma ligera hecha de perlas de poliestireno expandidas con vapor. Tiene pequeñas células cerradas que bloquean bien el calor. Es fuerte, resistente al agua y fácil de manejar. Estas cualidades lo hacen ideal para aislamiento y construcción de conductos.

Métodos de moldeo EPS para piezas de conducto HVAC

El moldeo de EPS forma perlas de espuma en piezas utilizando moldes personalizados. El calor y la presión forman piezas como codos, reductores o conductos rectos. Estas partes tienen aislamiento incorporado. Esto elimina la necesidad de envoltura o recubrimiento adicional.

Comparación con los materiales aislantes tradicionales

En comparación con la fibra de vidrio o la lana mineral, el EPS mantiene mejor su forma. Es más fácil de instalar. A diferencia de los materiales fibrosos, el EPS no necesita protección contra el agua o los insectos. Resiste naturalmente a estos problemas, durando más tiempo con menos cuidado.

Ventajas clave del moldeo EPS en sistemas de conductos HVAC

Los conductos moldeados en EPS ofrecen muchos beneficios. Esto mejora la eficiencia del edificio y facilita los proyectos.

Mejor rendimiento térmico y menos pérdida de calor

El EPS tiene una baja conductividad térmica, alrededor de 0,032 W/m·K. Esto reduce el intercambio de calor entre el aire del conducto y el exterior. En el transporte biofarmacéutico, las cajas de EPS con esta conductividad mantuvieron las temperaturas estables durante 96 horas. Es una mejora del 40%. Lo mismo se aplica a los conductos HVAC, manteniendo el aire estable a largas distancias.

Diseño ligero y instalación sencilla

Las piezas de EPS son mucho más ligeras que los conductos metálicos con aislamiento añadido. Esto los hace más fáciles de llevar e instalar. Reduce la tensión en los techos o paredes. En usos automotrices, las piezas de EPS de alto impacto (resistencia a la compresión 5,2 MPa) reducen el peso en un 37%. Esto ahorró costos. Del mismo modo, las piezas ligeras de HVAC aceleran los proyectos de construcción.

Resistencia al agua y sellos apretados

El EPS no absorbe agua, lo que evita el moho en los conductos. Sus juntas moldeadas encajan bien, a diferencia de los conductos metálicos con aislamiento envuelto. En el control de inundaciones, los módulos EPS hidrófobos (tasa de absorción de agua < 0,5%) se reutilizaron el 99% del tiempo. Esto muestra cómo la resistencia al agua prolonga la vida útil del conducto.

Larga duración y bajo mantenimiento

A diferencia de la fibra de vidrio, que puede caer o romperse, el EPS se mantiene fuerte. Resiste al desgaste por vibraciones o exposición. Necesita poco mantenimiento o reemplazo.

Tipos de grados de EPS utilizados en sistemas HVAC

Los diferentes grados de EPS satisfacen las necesidades específicas de HVAC.

Grado común para usos estándar

El EPS de grado común es asequible y funciona bien para conductos interiores. Es ideal para proyectos con bajo riesgo de incendio. Proporciona aislamiento constante con el tiempo.

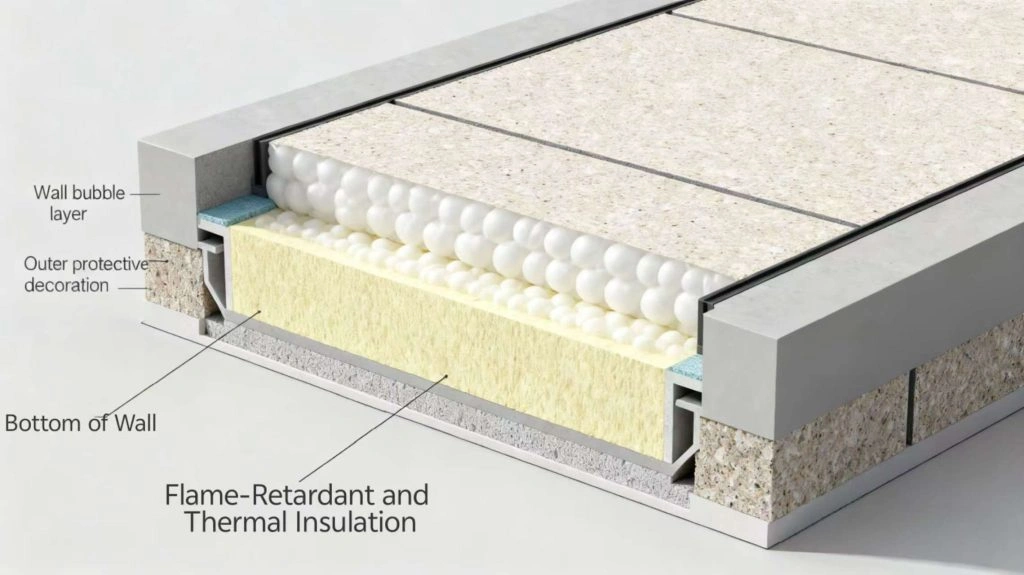

Grado retardante de llama para la seguridad contra incendios

El grado retardante de llama B1 de HUASHENG EPS (densidad 22kg / m³) cumple con los estrictos códigos de incendio. Es seguro para edificios comerciales o concurridos. Mantiene un fuerte aislamiento al tiempo que garantiza la seguridad.

Grado de grafito para el aislamiento térmico superior

Grafito Grado EPS tiene partículas de carbono que reflejan el calor. Esto reduce aún más la conductividad térmica. Es perfecto para espacios que necesitan aislamiento delgado pero fuerte.

Grado de protección ambiental para proyectos verdes

Para edificios respetuosos con el medio ambiente, el grado de protección ambiental EPS de HUASHENG es 100% reciclable. En el embalaje EcoPack, aumentó las puntuaciones ESG en 22 puntos. Apoya los objetivos verdes mientras cumple con los estándares.

Grado de negro de carbono para la durabilidad al aire libre

Carbon Black Grade EPS es resistente a los daños UV. Es ideal para conductos o ventilaciones al aire libre. Se mantiene fuerte bajo la luz del sol.

REPS personalizados para necesidades únicas del proyecto

HUASHENG ofrece REPS (Poliestireno Expandido Reforzado) personalizado. Estos se adaptan a densidades, formas o recubrimientos específicos. Cumple con las exigencias únicas de la construcción.

Ahorro de energía por conductos HVAC moldeados con EPS

Los conductos EPS mejoran el rendimiento energético de manera clara.

Menores necesidades de calefacción y refrigeración

Los conductos de EPS, especialmente el grado de grafito o el grado retardante de llama, reducen la pérdida de calor. Esto reduce la energía necesaria para calentar o enfriar. Mejora la eficiencia del sistema durante todo el año.

Reducción de las facturas de energía con el tiempo

Menos esfuerzo en los sistemas HVAC significa un menor uso de electricidad. Esto ahorra dinero en facturas para hogares y empresas. En el proyecto GreenBuild Eco-city, el EPS de grado retardante de llama B1 ahorró un 14% en energía.

Apoyo para certificaciones de edificios verdes (por ejemplo, LEED)

El uso de EPS de grado retardante de llama B1 de HUASHENG ayudó a los proyectos a obtener la certificación LEED Gold. Los conductos EPS cumplen con los estándares energéticos para la sostenibilidad global.

Retos y consideraciones para EPS en sistemas HVAC

El EPS tiene grandes beneficios, pero algunos factores necesitan atención para grandes proyectos.

Fuerza bajo alta presión

El EPS es fuerte pero puede necesitar soporte adicional para la ventilación a alta presión. Los ingenieros deben comprobar la capacidad de carga. REPS personalizados pueden ayudar si es necesario.

Normas y normas de seguridad contra incendios

Algunos códigos de construcción limitan los materiales inflamables, incluso con retardantes de llama. Los productos de EPS deben cumplir con las normas de incendio EN / ASTM para su aprobación.

Trabajar con otros sistemas de construcción

Los conductos de EPS deben conectarse bien con sistemas mecánicos, eléctricos o de plomería. El diseño cuidadoso asegura que las articulaciones manejen la vibración o la expansión.

HUASHENG: Un proveedor confiable de soluciones EPS de alta calidad para HVAC

HUASHENG, con sede en Lanzhou, se especializa en soluciones de polímeros avanzados. Proporcionan moldeo de EPS a medida para la construcción, incluyendo conductos de HVAC aislados para hogares y empresas.

Visión general de los productos y la experiencia de HUASHENG

HUASHENG ofrece varios grados de EPS para necesidades específicas:

Productos EPS de grado común

Estas opciones económicas funcionan para conductos interiores con bajo riesgo de incendio. Proporcionan aislamiento fiable durante años.

Grado retardante de llama para proyectos críticos a la seguridad

El EPS de grado retardante de llama B1 de HUASHENG, utilizado en GreenBuild Eco-city, ahorró un 14% en energía. También redujo el tiempo del proyecto en 18 días en comparación con la lana de roca.

Grado de grafito para necesidades de alta eficiencia

Graphite Grade EPS es ideal para espacios que necesitan aislamiento fuerte en diseños delgados. Cumple con las exigencias de la construcción moderna.

Grado de protección ambiental para la construcción ecológica

El 100% reciclable Grado de Protección Ambiental EPS de HUASHENG ganó el Premio de Diseño iF alemán de 2024 para envases electrónicos. Apoya la construcción verde sin perder calidad.

Grado de negro de carbono para la fuerza al aire libre

Negro de carbono grado EPS resistente a los rayos UV. Es perfecto para conductos de techo o ventilaciones al aire libre.

REPS personalizados para las necesidades específicas del cliente

HUASHENG proporciona REPS personalizados con densidad a medida (por ejemplo, 22kg / m³) y refuerzos. Cumple con las normas ISO/EN. Visite www.r-eps.com para obtener soporte con diseños complejos.

Resumen de los beneficios del moldeo EPS en sistemas HVAC

El moldeo EPS mejora los conductos para la eficiencia y la sostenibilidad:

- Ahorra hasta un 14% en energía.

- Las piezas ligeras son fáciles de manejar.

- La resistencia al agua evita el moho.

- Los materiales duraderos reducen los costos a largo plazo.

- Los grados flexibles cumplen con varias reglas y necesidades.

Desde hogares hasta fábricas, los conductos EPS reducen los costos y mejoran la comodidad durante todo el año.

Preguntas frecuentes

Q1: ¿Puede el EPS moldeado usarse de forma segura en edificios comerciales?

R: Sí. Grado retardante de llama B1 de HUASHENG cumple con estrictas normas de seguridad contra incendios. Es seguro para espacios comerciales y bien aisla.

Q2: ¿Cómo mejora el EPS de grado de grafito el ahorro de energía?

R: Las partículas de grafito reflejan el calor, disminuyendo la conductividad térmica. Esto mantiene el aire del conducto estable.

Q3: ¿Hay una opción EPS ecológica?

R: Sí. El grado de protección ambiental de HUASHENG es 100% reciclable. Apoya edificios verdes sin perder calidad.