El poliestireno expandido (EPS) es conocido por ser económico y útil en muchos campos, desde la construcción de casas hasta el empaquetado de mercancías. Pero es EPS realmente “ barato”? Para responder a esto, necesitamos ver lo que afecta su precio, como materias primas, grosor, envío y diseños personalizados. Esta guía desglosa estos factores para mostrar por qué el EPS es asequible.

Descripción general del poliestireno expandido

¿Qué es el poliestireno expandido (EPS)?

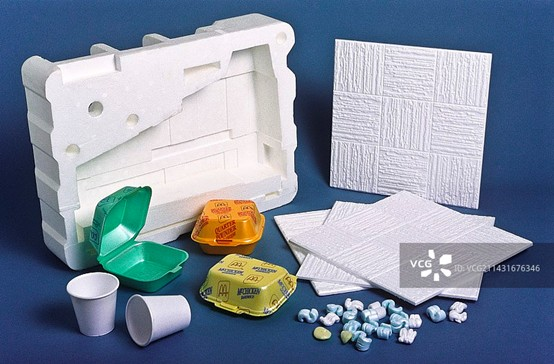

El poliestireno expandido, o EPS, es una espuma ligera y fuerte llena de pequeñas burbujas de aire. Comienza como pequeñas perlas de poliestireno. Estas perlas se expanden con vapor y un gas especial, luego se moldean en bloques o formas. A todo el mundo le gusta el EPS porque mantiene las cosas calientes o frías, protege contra golpes y se mantiene seco.

Aplicaciones comunes de EPS en diversas industrias

El poliestireno expandido se utiliza en muchas áreas. En la construcción, los productos de poliestireno expandido de HUASHENG son de primera clase. Ayudan a los edificios a mantenerse calientes y ahorrar energía. Para el embalaje y el envío, HUASHENG hace espuma EPS ligera pero resistente. Esto mantiene los artículos delicados, como la electrónica, seguros durante el transporte.

Propiedades clave que influyen en el costo

Características como lo bien que los productos de poliestireno expandido resisten al calor, su tenacidad, protección contra incendios y capacidad de reciclarse cambian su precio. El tipo y el grosor elegido para una tarea también importa mucho en el establecimiento del costo.

Factores que afectan el costo del poliestireno expandido

Comprender lo que aumenta o disminuye el precio de EPS muestra si es realmente asequible.

Materias primas y gastos de fabricación

Hacer EPS implica pasos que pueden ser costosos.

Requisitos de vapor y energía

El proceso utiliza vapor y calor para expandir las perlas. Las fábricas con sistemas de energía inteligentes, como las que utilizan energía solar o eólica, pueden ahorrar dinero en comparación con las que no lo hacen.

Pentano y Cuentas de Pre-expansión

El pentano es un gas que ayuda a las perlas a crecer. Su precio puede cambiar, afectando los costos de EPS. Además, las máquinas utilizadas para la pre-expansión se suman a los gastos de puesta en marcha.

Variaciones de densidad y grado

Lo grueso o especial que es el EPS cambia su precio.

Impacto de la densidad en el precio por unidad de volumen

El EPS más grueso utiliza más material, por lo que cuesta más. El EPS más ligero es más barato por metro cúbico, pero puede que no sea lo suficientemente fuerte para algunos trabajos.

Diferencias entre los grados: EPS estándar vs. especializado

Tipos especiales, como Grado retardante de llama o Grado de grafito, se hacen para necesidades específicas. Costan más que el grado común. Por ejemplo, las partículas de EPS retardantes de llama B1 en el proyecto GreenBuild Eco-city aumentaron el ahorro de energía en un 14% y redujeron el tiempo del proyecto en 18 días. Su precio más alto vale la pena por los beneficios.

Consideraciones de transporte y almacenamiento

El envío y almacenamiento de EPS también afectan su costo total.

Naturaleza ligera vs. costos de volumen

El EPS es súper ligero, lo que reduce los gastos de envío en función del peso. Pero ocupa mucho espacio. Esto puede aumentar los costos de transporte a menos que esté empaquetado bien.

Implicaciones del envasado y la manipulación

El EPS necesita ser manejado con cuidado porque es voluminoso. Sin embargo, ahorra dinero al no necesitar materiales de embalaje adicionales. Los productos de poliestireno expandido de HUASHENG reducen el desperdicio de materiales no respetuosos con el medio ambiente, reduciendo los costos de embalaje con el tiempo.

Comparación del poliestireno expandido con materiales alternativos

Para ver si el EPS es asequible, debemos compararlo con otras opciones de aislamiento.

EPS vs. espuma de poliuretano

La espuma de poliuretano aisla mejor por pulgada, pero es mucho más cara que el EPS. Para proyectos en los que ahorrar dinero es más importante que pequeñas diferencias de aislamiento, EPS es la mejor opción.

EPS vs. Poliestireno Extrudido (XPS)

XPS es más fuerte y resistente al agua mejor, pero es más caro debido a su complejo proceso de fabricación. El poliestireno expandido funciona lo suficientemente bien para la mayoría de los trabajos a un costo más bajo.

EPS vs. opciones de aislamiento ecológicas

Las opciones verdes como la lana mineral o la celulosa son más amigables con el planeta, pero cuestan más porque son más difíciles de instalar o hacer. Las partículas EPS 100% reciclables de HUASHENG, utilizadas en el envasado EcoPack, redujeron los costos en un 28%. Esto hace que EPS sea respetuoso con el medio ambiente y con el presupuesto.

Ventajas económicas del uso de productos de poliestireno expandido

EPS no solo es barato de comprar, sino que ahorra dinero con el tiempo.

Valor a largo plazo en la construcción y el empaquetado

EPS mantiene los edificios calientes o frescos durante todo el año, reduciendo las facturas de energía. En el embalaje, evita daños durante el envío, por lo que hay menos necesidad de reemplazar artículos rotos.

Durabilidad y costos de mantenimiento a lo largo del tiempo

El EPS dura mucho tiempo sin romperse. Resiste al moho y se mantiene fuerte durante años. Esto significa menos costos de reparación en comparación con materiales que se desgastan más rápido.

Gama de precios para diferentes tipos de productos EPS

El mercado tiene muchos productos de poliestireno expandido para diferentes usos.

Tendencias de precios de EPS de grado común

Los bloques EPS blancos estándar, utilizados para aislamiento básico o embalaje, son los más baratos. Se fabrican en grandes cantidades con un proceso sencillo.

Comparación de costos de grados de retardante de llama y grafito

Los grados especiales como el grado retardante de llama o el grado de grafito cuestan más. Incluyen tratamientos adicionales para la seguridad contra incendios o un mejor aislamiento. Estos se utilizan en la cadena de frío o edificios prefabricados donde la seguridad es una necesidad.

Protección Ambiental y Precios de Negro de Carbono

Opciones ecológicas, como Negro de carbono Grado o contenido reciclado EPS, tienen precios más altos. Pero merecen la pena por su menor impacto ambiental. La huella de carbono de 1 tonelada de masterbatch de poliestireno expandible regenerado (R-EPS) es de 719,14 kilogramos de CO. ₂ equivalente, mostrando beneficios verdes claros.

Cómo la personalización influye en los precios del producto EPS

Los diseños personalizados agregan flexibilidad, pero pueden cambiar los costos dependiendo del proyecto.

Formas, tamaños y densidades a medida

El EPS de forma personalizada necesita herramientas especiales, lo que aumenta los costos iniciales. Pero es ideal para diseños únicos, como piezas decorativas de edificios o esculturas de arte. Estos agregan estilo sin romper el banco cuando se planifica bien.

Impacto del volumen de pedidos en los precios unitarios

Los grandes pedidos ahorran dinero debido a la producción a granel. Los pequeños lotes personalizados cuestan más debido a las tarifas de instalación repetidas.

Breve introducción a HUASHENG como proveedor confiable de EPS

Lanzhou Huasheng New Materials Co., Ltd es un primer nombre en la fabricación ecológica de EPS en el noroeste de China. Con el objetivo de "aliviar la carga de la tierra", HUASHENG lidera el camino en materiales sostenibles con solo una perla de poliestireno.

Resumen de la oferta de productos de HUASHENG

HUASHENG ofrece una amplia gama de productos:

- Grado comúnIdeal para las necesidades diarias.

- Grado retardante de llamaConstruido para seguridad contra incendios.

- Grado de grafito: Aumenta el aislamiento.

- Grado de protección ambientalUtiliza materiales reciclados.

- Negro de carbono GradoResiste a los rayos UV.

- Soluciones REPS personalizadasEmbalajes impresos en 3D hechos de EPS 100% reciclado, a medida para industrias como electrónica o edificios ecológicos.

Compromiso con la calidad, la sostenibilidad y la satisfacción del cliente

HUASHENG se centra en nuevas ideas y tecnología de primera clase. Su certificación de huella de carbono ISO 14067: 2018 demuestra que sus productos son de alta calidad y respetuosos con el medio ambiente. Premios como el iF Design Award 2024 de Alemania demuestran su éxito global.

Resumen de información clave sobre la asequibilidad de EPS

El poliestireno expandido es una de las opciones más amigables con la cartera cuando equilibra su rendimiento y el ahorro a largo plazo. Los grados especializados cuestan más debido a características adicionales o beneficios verdes. Pero ayudan a reducir el uso de energía y las emisiones de gases de efecto invernadero, haciendo que el EPS sea inteligente para los presupuestos y bueno para el planeta.

Preguntas frecuentes

Q1: ¿Es el poliestireno expandido más asequible que otros materiales de aislamiento? R: Sí. En comparación con la espuma de poliuretano o el poliestireno extruido (XPS), EPS ofrece beneficios similares a un precio más bajo. Su ahorro de energía con el tiempo lo hace aún más rentable.

Q2: ¿El grado de EPS afecta significativamente su precio?

R: Definitivamente. El grado común es más barato que los tipos especializados como el grado retardante de llama o el grado de grafito. Estos requieren pasos o aditivos adicionales, pero funcionan mejor donde cuenta.

Q3: ¿Se puede personalizar el poliestireno expandido sin aumentar drásticamente el costo? R: Sí. Con los métodos modernos de HUASHENG, los diseños personalizados que utilizan EPS reciclado pueden reducir los costos de envasado en hasta un 28%. Los grandes pedidos también reducen los costos a través de ahorros masivos.