Stellen Sie sich das vor: Sie haben gerade eine zarte Keramikviase online gekauft und sind gespannt darauf, dass sie auftaucht. Aber wenn die Box an Ihrer Tür landet, fangen Sie ein weiches Klappern von innen. Sie öffnen es und finden überall gebrochene Stücke. Alles aufgrund schwacher Verpackungssachen, die bei einem kleinen Schock im Versand fehlgeschlagen sind. Ärgerlich, ist’ T es? So etwas passiert täglich in der Liefer- und Lagerarbeit und zeigt, warum die Wahl des richtigen expandierten Polystyrol-Schaumstoffs – oder EPS-Schaumstoffs, wie es die Leute oft nennen – sehr wichtig ist. Als Top-EPS-Lieferant steht HUASHENG diesen Problemen gegenüber. In diesem Artikel werden wir uns anschauen, wie die Wahl der richtigen EPS-Klasse Ihre Waren schützen und Kosten senken kann. Am Ende werden Sie erkennen, warum die Zusammenarbeit mit einem soliden EPS-Anbieter die Dinge zum Besseren ändern kann.

Zwei Schlüsselfaktoren: Dichte und Stärke

Wenn es um expandierte Polystyrol-Verpackungen geht, wird nicht jeder EPS-Schaum gleich geschaffen. Dichte und Festigkeit zeichnen sich als die wichtigsten Elemente aus, die beeinflussen, wie gut Ihre Verpackung funktioniert. Machen Sie diese falsch, und Sie könnten am Ende mit zerkleinerten Kästen oder höheren Versandkosten. Bringen wir sie ein für ein ab.

- Dichte: Ausgleich zwischen Polsterung und Gewicht

Dichte in EPS-Schaum bedeutet, wie viel Sache in einen festgelegten Raum verstopft wird, oft in Pfund pro Kubikfuß oder Gramm pro Liter überprüft. Leichterer Dichte EPS Schaum wiegt in der Regel weniger und kostet billiger pro Stück, aber es kann nicht genügend Polsterung für schwere Dinge geben. Auf der anderen Seite bringt dichteres Material eine bessere Beutelung, obwohl es die EPS-Schaumstoffkosten erhöht.

Doch es geht nicht nur darum, hoch oder niedrig zu gehen. Sie müssen über das Gewicht des Artikels nachdenken und wie leicht es bricht. Zu dick, und Sie werfen Geld auf unnötige Bits weg. Zu dünn, und deine Sachen erscheinen verletzt. Als EPS-Lieferant empfehlen wir, Proben auszuprobieren, um diesen guten Punkt zu erreichen. Seltsamerweise überspringen einige Leute, wie Dichte das Stapeln trifft - dünnere EPS-Schaumstoffkosten können zu schwankenden Stapeln führen, wenn sie nicht gut eingerichtet sind.

- Druckfestigkeit: Unterstützung von Lasten und Stabilität

Die Druckfestigkeit misst, wie viel Gewicht EPS-Schaum verarbeiten kann, bevor er sich verformt oder zerkleinert. Es ist entscheidend für expandierte Polystyrol-Verpackungen, die in Lagern oder LKW gestapelt werden. Stärkeres Material bedeutet bessere Unterstützung, aber nochmals erhöht es die EPS-Schaumstoffkosten ohne Mehrwert.

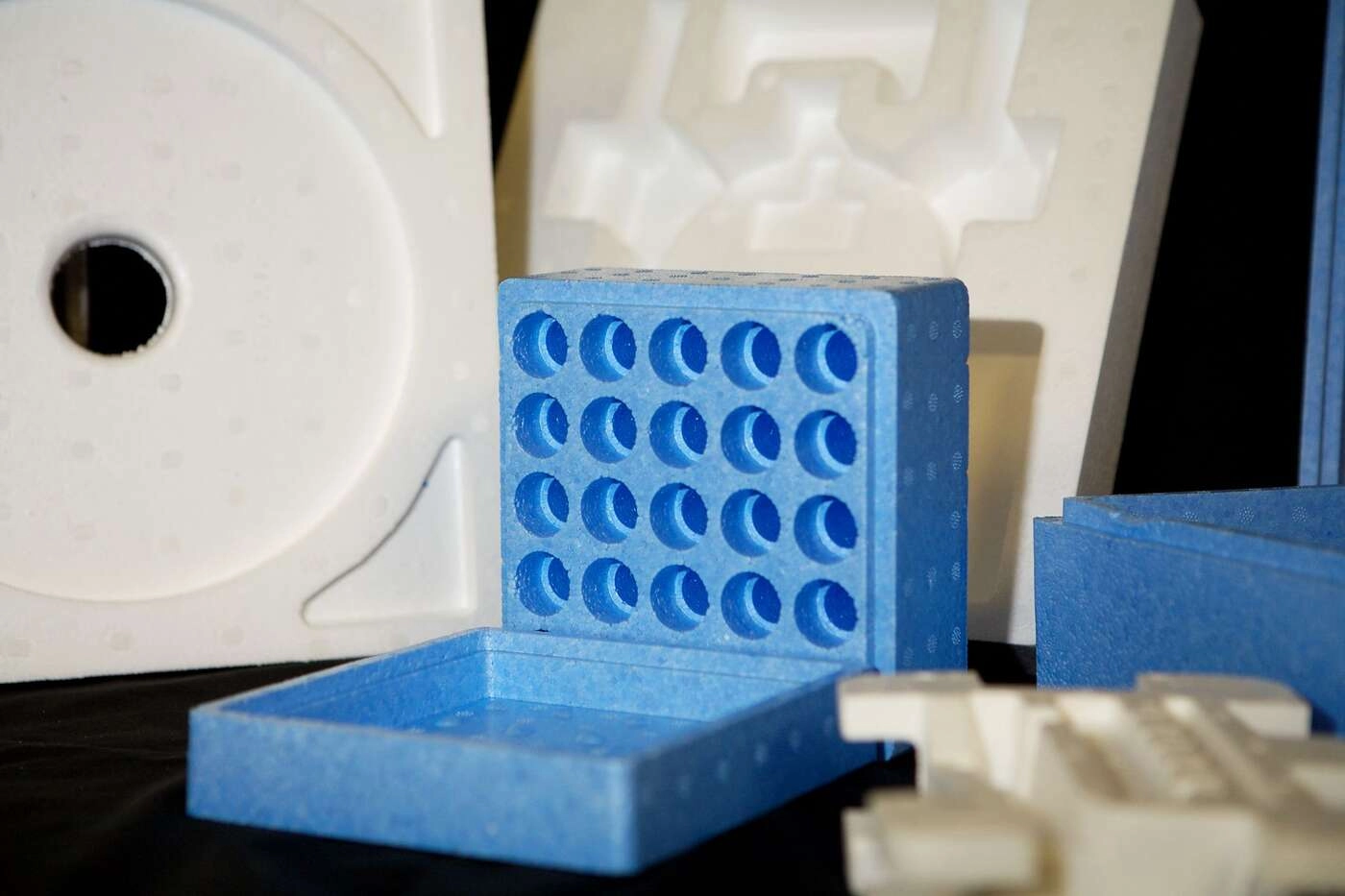

Praktisch gesehen benötigen Sie für Gegenstände wie Geräte möglicherweise EPS-Schaum mit einer Druckfestigkeit von über 10 psi, um einen Zusammenbruch während des Transports zu verhindern. Wir’ Wir haben Fälle gesehen, in denen Kunden niedrige Festigkeit EPS-Schaumstoffkosten für schwere Elektronik verwendet haben, nur um Ansprüche von zertrennten Produkten zu stellen. HUASHENGs Qualitäten, wie auch unsere Rapid Prototyping B-Klasse, zeichnen sich hier durch eine starke Perlenfusion aus, die die gesamte Haltbarkeit verbessert. Dies ist’ t nur sprechen; Labortests zeigen, dass unser expandierter Polystyrol-Schaumstoff die Integrität unter Lasten behält, die 15-20% höher sind als grundlegende Alternativen.

Bei HUASHENG mischen wir diese Faktoren nahtlos. Unsere maßgeschneiderten EPS-Schaumstoffoptionen ermöglichen Anpassungen an Dichte und Festigkeit, so dass Sie Verpackungen erhalten, die auf Ihre Bedürfnisse zugeschnitten sind, ohne überschüssige Ausgaben.

Passen Sie die ideale EPS-Qualität an Ihr Produkt an

Nachdem Sie Dichte und Stärke erhalten haben, verwendet der folgende Schritt sie an tatsächlichen Stellen. Abwechslungsreiche Waren erfordern unterschiedliche EPS-Schaumstoffqualitäten. Fehler machen kann langsame Arbeit oder Flops verursachen. Wir werden drei übliche Setups überprüfen, die sich aus langen Jahren der Bereitstellung von expandierten Polystyrol-Verpackungen in vielen Bereichen ziehen. Auf diese Weise hilft Käufern bei der Vermeidung von Raten und Prüfgebühren.

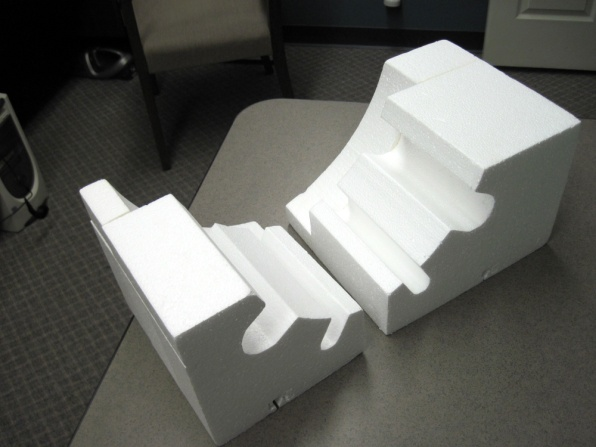

- Szenario A: Schwere oder Präzisionsgeräte

Für sperrige Gegenstände wie Waschmaschinen oder empfindliche Elektronik ist EPS-Schaumstoff mit höherer Dichte oft der richtige Weg. Diese Produkte benötigen eine robuste Dämpfung, um Stöße von Tropfen oder Vibrationen zu absorbieren. Eine höhere Dichte bei 12 g/l oder höher sorgt für eine überlegene Stoßbeständigkeit. In einem Projekt lieferten wir kundenspezifischen EPS-Schaumstoff für TV-Verpackungen, wodurch Beschwerden um 25% reduziert wurden. HUASHENGs Standard E-Klasse passt hier, mit seiner gleichmäßigen Ausdehnung, die eine konsistente Leistung gewährleistet. Gleichzeitig ermöglicht die starke Druckfestigkeit eine höhere Stapelung und spart Lagerplatz.

Einkäufer hängen sich jedoch manchmal an Spezifikationen und übersehen die gesamte Logistikkette. Wir raten Kunden, die Auswirkungen des LKW-Transports zu berücksichtigen, was den Bedarf an Materialien mit höherer Dichte erhöhen kann.

- Szenario B: Leichte, aber zerbrechliche Gegenstände

Für diese Produkte, wie Keramik oder Handwerk, ist die primäre Bedrohung Schock, nicht Zerkleinerungsgewicht. Eine mitteldichte Qualität mit hoher Widerstandsfähigkeit und hervorragenden Dämpfungseigenschaften ist oft die kostengünstigste Lösung. Es absorbiert Schlagenergie effizient ohne die Kostenprämie der ultrahohen Festigkeit. Für noch leichtere Anwendungen, wie zum Beispiel verderbliche Güter, ändern sich die Prioritäten erneut.

- Szenario C: Kostensensitiv Langlebige Anwendungen

EPS-Verpackungen mit niedriger bis mittlerer Dichte (ca. 0,7-1,0 pcf) können die Wärmedämmungsleistung aufrechterhalten und gleichzeitig kostengünstig bleiben. Darüber hinaus reduziert recycelter expandierter Polystyrolschaum die Umweltbelastung. Wenn umweltfreundliche Materialien eine Priorität haben, HUASHENG Rapid Prototyping Klasse B EPSdie umweltfreundlich und schnell produzierbar ist, ist eine ideale Wahl für die Verpackung von saisonalen Früchten.

Produktionseffizienz und EPS-Verarbeitungsfähigkeit

Die wahren Kosten eines EPS-Pakets sind nicht nur die Rohstoffe; Es wird auch auf Ihrem Produktionsboden festgelegt. Die Verarbeitungsfähigkeit der EPS-Perlen beeinflusst direkt Ihre Betriebseffizienz und damit Ihren Endergebnis.

Eine EPS-Klasse, die ungleichmäßig läuft oder langsamere Zykluszeiten auf automatischen Formmaschinen erfordert, kann Engpässe schaffen, den Energieverbrauch erhöhen und aufgrund von Mängeln wie schlechter Fusion zu höheren Ablehnungsraten führen. Daher ist ein Material, das „reibungslos auf automatischen oder elektrisch angetriebenen Maschinen mit schnelleren Zyklen läuft“, ein wesentlicher Vorteil. Es maximiert den Durchsatz und minimiert Ausfallzeiten. Dies unterstreicht die Wichtigkeit der Auswahl eines Anbieters, der für stabiles EPS-Schaumstoffgießen bekannt ist. Konsistentes, zuverlässiges Materialverhalten von Charge zu Charge ist unerlässlich, um einen reibungslosen, vorhersehbaren und profitablen Herstellungsprozess aufrechtzuerhalten. Diese Betriebsstabilität ist ein versteckter, aber wesentlicher Bestandteil der Kostenoptimierung.

Schlussfolgerung

Die Auswahl der richtigen EPS-Klasse ist keine schnelle Wahl – es geht darum, den Schutz gegen die Gesamtkosten, vom Material bis zum Versand, zu waagen. Indem Sie sich auf Dichte, Festigkeit und Produktpassform konzentrieren, vermeiden Sie häufige Fallstricken. Wie wir gesehen haben, HUASHENGOptionen wie die B-Klasse für Rapid Prototyping liefern echten Wert.

Bereit, Ihre expandierte Polystyrolverpackung zu verfeinern? Kontaktieren Sie unser Team unter info@r-eps.com für fachliche Beratung, Proben oder maßgeschneiderte EPS-Schaumlösungen. Wir sind hier, um Ihnen dabei zu helfen, effiziente, kostengünstige Verpackungen zu bauen, die funktionieren.