Das flammhemmende Polystyrol verbessert den Schutz des Gebäudes, indem es spezielle chemische Zusatzstoffe erhält, die eine schützende Kohlenstoffschicht bilden, wenn es Hitze trifft. Dieser Prozess verzögert den Brandstart, verlangsamt die Bewegung der Flammen und reduziert die Rauchproduktion. Dadurch gibt es wichtige zusätzliche Zeit für die Menschen, die Gegend zu verlassen. Das Material behält eine starke Wärmeblockierfähigkeit und spielt eine Schlüsselrolle bei genehmigten Außenwand- und Dachverstellungen. Durch die Einhaltung strenger Brandregeln hilft es, Brände an einem Ort zu halten, Wachen, die Kraft aufbauen, und schützt Leben in heute’ S Strukturen.

Wie trägt flammhemmendes Polystyrol zur Gebäudesicherheit bei?

Warum ist Brandsicherheit ein entscheidender Faktor bei der Auswahl moderner Baustoffe?

Brandschutz steht als grundlegender Bestandteil bei der Bauplanung und der Materialwahl. Brände können Menschen großen Schaden anrichten, zu riesigen Eigentumsverlusten führen und die Stärke von Strukturen schwächen. In überfüllten Stadtgebieten wachsen diese Gefahren noch mehr. Diese Situation erfordert eine stärkere Einhaltung der Brandsicherheitsvorschriften.

Um solche Gefahren zu verringern, haben Regierungsgruppen weltweit strenge Brandleistungsregeln für Isolierung, Außendeckel und andere Bauteile festgelegt. Diese Regeln verlangen, dass Materialien, die in Bauarbeiten verwendet werden, gegen Brände standhalten. Sie müssen auch begrenzen, wie sich Flammen ausbreiten und wie viel Rauch sich bildet. Materialien, die das Feuer verlangsamen, reduzieren, wie schnell es sich ausbreitet, und schaffen wertvolle Zeit für einen sicheren Austritt. Diese Verlangsamung des brennenden Fortschritts erweist sich als entscheidend für die Rettung von Leben und die Verringerung der Schäden an Gebäuden.

Wie verhält sich Polystyrol bei hohen Temperaturen ohne Flammschutzmittel?

Expandiertes Polystyrol (EPS) besteht in seiner üblichen Form aus einem Material auf Kohlenwasserstoffbasis. Es zeigt geringen Wärmedurchgang und leichtes Gewicht. Regelmäßige EPS hat jedoch bei hoher Hitze große Schwächen. Es fängt schnell Feuer und hilft den Flammen, sich vorwärts zu bewegen, was es zu einer Gefahr in vielen Anwendungen macht.

Normales expandiertes Polystyrol (EPS) beginnt leicht zu brennen und hilft der Flammenbewegung. Nach Beginn des Feuers setzt EPS dicken dunklen Rauch frei und erzeugt Schmelztropfen. Beide Faktoren verschlimmern das Brandwachstum und machen das Sehen während der Flucht schwieriger.

Diese Aktionen schaden auch den Bemühungen, Feuer in einem Abschnitt eines Gebäudes zu halten. Die Abgabe von brennenden Gasen und der Verlust der Materialfestigkeit verursachen einen schnellen Zusammenbruch von Wänden, die den Branddurchgang verlangsamen sollen, wodurch die Abschnittskontrolle und die Bauwiderstand bei Bränden geschwächt werden.

Welche Änderungen machen Polystyrol flammhemmend?

Welche chemischen Behandlungen werden verwendet, um die Brandbeständigkeit von EPS zu erhöhen?

Um die brennende Natur von EPS zu bewältigen, fügen Hersteller während der Herstellung feuerfeste Substanzen direkt in das Material hinzu. Diese Substanzen, einschließlich Verbindungen mit Halogenen oder Systeme auf Basis von Phosphor, reagieren mit Wärme auf chemische Weise.

Stoffe wie Halogen- oder Phosphortypen mischen sich während der Formstufe ein. Wenn hohe Hitze ankommt, helfen diese Gegenstände, einen Kohlenstoffschild auf der Außenseite aufzubauen. Dieser Schild wirkt als Wärmeblock, der die Verbrennung verzögert.

Diese Substanzen schaffen eine Schutzkohlenstoffschicht unter Hitze. Es verlangsamt das Brennen. Gleichzeitig stoppen sie die Freisetzung von Gasen, die leicht brennen, und reduzieren die Lufterreichung im Inneren des Materials. Dieser Doppeleffekt spielt eine große Rolle bei der Senkung, wie stark und lange das Feuer dauert.

Wie wirken sich diese Änderungen auf die Wärmedämmungsleistung aus?

Auch mit zusätzlichen Feuerwiderständen behält EPS seine wichtigsten hitzeblockierenden Eigenschaften. Feuerbeständiges EPS hält den Wärmedurchgang gering und gewinnt gleichzeitig eine bessere Widerstandsfähigkeit gegen Brände, was für Anwendungen wie Außenwandsisolationssysteme (EWIS) sehr wichtig ist.

Diese Änderungen beeinträchtigen die Ergebnisse über verschiedene Dickenebene nicht. Die Wärmeblockierende Leistung bleibt bei verschiedenen Dickenarten gleich. Bauherren und Planer können sich somit für brandfeste EPS entscheiden, weil sie ihre Ziele für Energieeinsparung und Sicherheit erfüllen.

In welchen Anwendungen ist flammhemmendes EPS am effektivsten?

Warum wird es weit verbreitet in Außenwandsisolationssystemen (EWIS)?

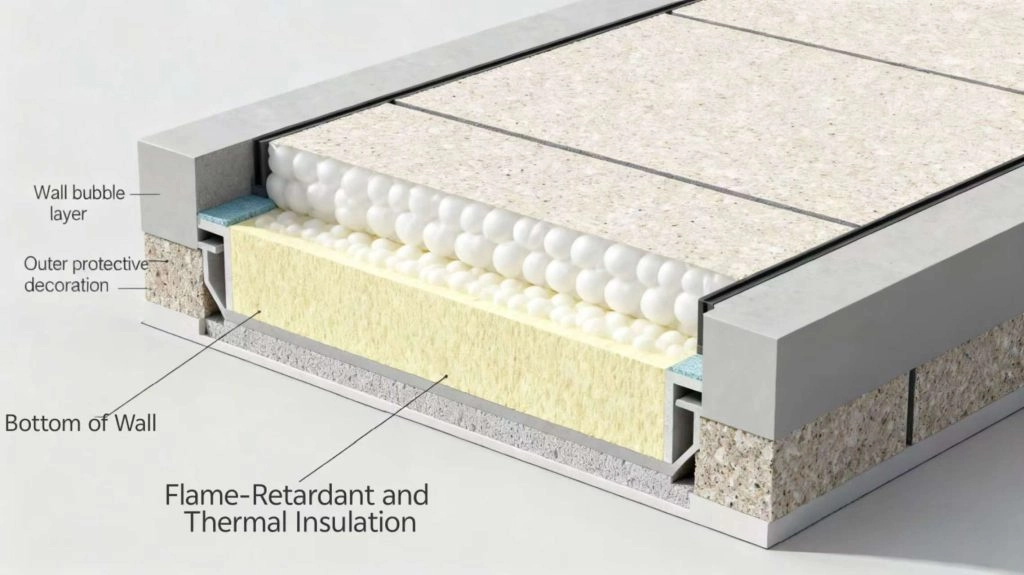

EWIS benötigt Materialien, die eine hervorragende Wärmeblockierung bieten und gleichzeitig hohe Brandsicherheitsniveaus erfüllen. Flammschutz EPS behandelt beide Bedürfnisse gut.

EWIS erfordert Produkte, die Wärmeeinsparung mit strengen Brandwirkungsklassen ausgleichen. EPS, die nach EN 13501-1 die Stufe B1 oder B2 erreicht, wird oft für mittlere und hohe Gebäude zugelassen.

Brandfestes EPS Befolgt die Sicherheitsvorschriften für Außenwände in mittleren und hohen Konstruktionen. Sein leichtes Make-up erleichtert auch die Arbeit während der Einrichtung und senkt das zusätzliche Gewicht auf den Rahmen, was bei der Aktualisierung alter Gebäude oder der Herstellung energiesparender Außenwände sehr nützlich ist.

Wie funktioniert es in Dachsystemen unter Brandszenarien?

Dachteile sind einem höheren Risiko gegenüber äußeren Feuerstartern wie fliegenden heißen Stücken oder Hitzewellen ausgesetzt. Dach verwendet Gewinn aus EPS, der sich dem Start von solchen Quellen widersteht. Flammschutz EPS verzögert die Flammenbewegung über weite flache Bereiche. Dies hilft, die Dachfestigkeit in frühen Brandzeiten zu erhalten.

Korrekt bewertetes EPS verlangsamt die Flammenverstreibung auf großen flachen Flächen. Diese Eigenschaft kann auseinanderfallen oder weiten Schaden verschoben, weil sie Hilfsteams mehr Zeit zum Handeln gibt. Das Material hilft bei der Festigkeit des Daches während der Anfangsbrandphasen.

Was sind die Industriestandards für flammhemmende EPS?

Welche Prüfmethoden bestimmen die Brandklassifizierung von EPS-Produkten?

Die Brandgruppierung hängt von Standard-Testmethoden ab, die mehrere Brennfaktoren prüfen. Die üblichen Tests umfassen EN 13501-1, UL 94, ASTM E84 und ISO 5660, wie Materialien auf Feuer reagieren.

Diese Tests untersuchen Maßnahmen wie Oberflächenflammenbewegung, Rauchwachstumspunkt (SDI), Wärmefreisetzungsgeschwindigkeit (HRR) und abgegebene Gesamtwärme (THE). Faktoren wie Flammenausbreibung, Rauchwachstum und Wärmefreisetzungsgeschwindigkeit erhalten eine Überprüfung.

Um die Genehmigung für kontrollierte Gebäude zu erhalten, müssen EPS-Elemente festgelegte Grenzen erreichen oder überschreiten. Waren müssen die niedrigsten Niveaus für den Einsatz an regierten Baustellen erfüllen.

Wie vergleichen sich verschiedene Flammschutzqualitäten EPS in Leistungsbewertungen?

EPS-Mischungen ändern sich je nach Stoffmengen, geplanten Verwendungen und Festigkeitsbedarf. Zum Beispiel: Licht flammhemmende Klasse-FB bietet einen verbesserten Schutz für leichte Bauteile.

Für schwierigere Einstellungen wie Fabriken oder öffentliche Arbeiten bieten Hersteller stärkere Wahlmöglichkeiten. Optionen mit hohem Ergebnis wie Flammschutzqualität – FS passen zu schwierigen Orten wie Fabriken oder öffentlichen Gebäuden.

HUASHENG bietet ein breites Sortiment einschließlich F-Grade (üblicher Flammschutz), FB-Grade (leichtes Gewicht), FS-Grade (hohe Leistung) und FSH-Grade (europäischer Standard B1). FSH-europäischer Standard flammhemmender Grad passt Wärmeblockierung in Bau- und Fabrikarbeit, Passivhaus Wärmeeinsparung.

Wie gewährleisten Hersteller eine konsistente Brandleistung über Chargen hinweg?

Welche Qualitätskontrollmaßnahmen werden während der Produktion umgesetzt?

Hersteller verwenden erweiterte Kontrollsysteme bei allen Schritten, um die Ergebnisse stabil zu halten. Sie beobachten Perlenwachstumsraten, sogar die Ausbreitung von Additiven und Trocknungszeiten. Diese Punkte wirken sich direkt auf die Endaktion des Objekts unter Feuer aus.

Jede Gruppe erhält vor dem Versand Checks gegen die angegebenen Details. Gruppenprüfungen stellen sicher, dass die angegebenen Brandergebnisse vor dem Versand verfolgt werden. Auch die Stärke im Laufe der Zeit erhalten Überprüfung, um Vertrauen während der Nutzung der Website zu halten. Lange Haltbarkeit erhält auch Kontrollen für Standortstabilität.

Warum ist Rückverfolgbarkeit wichtig für die Einhaltung von Bauprojekten?

Bauarbeiten, die Gesichtskontrollen erfordern, benötigen vollständige Aufzeichnungswege. Die Genehmigungspapiere müssen den Artikelmarken entsprechen, um die Kontrollanforderungen zu erfüllen. Diese Übereinstimmung beweist sich als materiell geeignet für bestimmte Regelsätze.

Wenn spätere Bewertungen oder Ereignisse stattfinden, müssen die Hersteller Aufzeichnungen zur Verfügung stellen. Aufzeichnungen, die die Verantwortung für die Hilfe in späteren Gebäudeprüfungen oder Ereignissen zurückverfolgen können. HUASHENG baut die Verfolgung in sein Qualitätssystem über seine intelligente Herstellungslinie ein.

Warum wählen Sie HUASHENG für hochsichere flammhemmende EPS-Lösungen?

HUASHENG hat sich über viele Jahre neue Ideen in erweiterten Polystyrol-Methoden für starke Bauanwendungen gewinnen. Ihr Fokus auf brandsichere Mischungen erfüllt weltbekannte Regeln und behält gleichzeitig den besten Wärmeblockierwert.

Ihr Produktsortiment umfasst spezielle Flammschutzniveaus, die für zu Hause und Geschäftsarbeiten entwickelt wurden. Sie balancieren Maschinenstärke mit großer Hitzebeständigkeit und bewährter Brandwirkungsgruppierung.

Was HUASHENG abhebt, liegt in seinem vollen Qualitätsversprechen. Es deckt jeden Schritt ab, von der Auswahl der Ausgangsstoffe bis zur letzten Artikelkontrolle. Dies gewährleistet, dass jede Gruppe stetige Wache an den Standorten bringt.

Arbeitnehmer, die nach zuverlässigem flammhemmendem Polystyrol suchen, können sich die Produkte von HUASHENG durch ihre Hauptwege ansehen. Diese erfüllen die Sicherheitsvorschriften und verbessern gleichzeitig die Energieergebnisse.

Häufig gestellte Fragen

F: Ist flammhemmendes Polystyrol für alle Gebäudearten einschließlich Hochhäuser geeignet?

A: Ja, wenn es nach regionalen Codes richtig bewertet ist, kann flammhemmendes Polystyrol sicher in mittleren und hohen Gebäuden als Teil konformer Fassadensysteme oder innerer Isolationsschichten verwendet werden.

F: Beeinflusst das Hinzufügen von Flammschutzmitteln die ökologische Nachhaltigkeit von EPS-Produkten?

A: Während Additive das chemische Profil leicht verändern, sind viele moderne Formulierungen mit minimalen ökologischen Auswirkungen konzipiert und erfüllen die Umweltsicherheitsstandards bei der Verwendung und Entsorgung.

F: Kann reguläres Polystyrol vor Ort mit Oberflächenbeschichtungen oder Verpackungen aufgerüstet werden, um seine Brandqualität zu verbessern?

A: Oberflächenbehandlungen können eine begrenzte Verbesserung bieten, ersetzen jedoch nicht die Notwendigkeit von vollständig integrierten Flammschutzmitteln innerhalb der Materialmatrix; Zertifiziertes Flammschutzmittel EPS sollte von Anfang an für eine zuverlässige Leistung spezifiziert werden.