Foam Polystyrene Beads and EPS Applications

Foam polystyrene beads and their puffed-up version, EPS, are total rockstars for stuff like packaging and building. These little guys come from a slick chemical trick, turning into light, tough materials with a ton of uses. They expand like crazy and stay strong, making them awesome for protecting delicate items or keeping buildings cozy.

How Foam Polystyrene Beads Are Made

Foam polystyrene beads come from a plastic called polystyrene. This material is a type of thermoplastic made by linking styrene molecules together. To create these beads, workers use a process called suspension polymerization. In this method, tiny drops of styrene float in water. Then, they turn into solid beads through a chemical reaction. After that, a gas called pentane is added to the beads. This gas helps the beads grow bigger when heated.

The size and weight of these beads can be carefully adjusted during the process. This control affects how the beads work in different products. For example, the E-standard grade E-101 has a size of 1.30-1.60mm and can expand 70-90 times its original size. This makes it great for things like packaging or keeping things warm.

Properties and Uses of Expanded Polystyrene

Expanded Polystyrene (EPS) is made by heating foam polystyrene beads. This creates a light but firm structure with tiny air pockets. When beads with more weight are used, EPS becomes very strong. It can handle heavy loads without breaking. EPS panels made from these beads stay the same size and shape, even under pressure.

The E-standard material works well in machines that shape products automatically. It offers strong support and fits many uses, like building walls with insulation called insulated concrete forms (ICFs).

What Makes EPS an Effective Thermal Insulator?

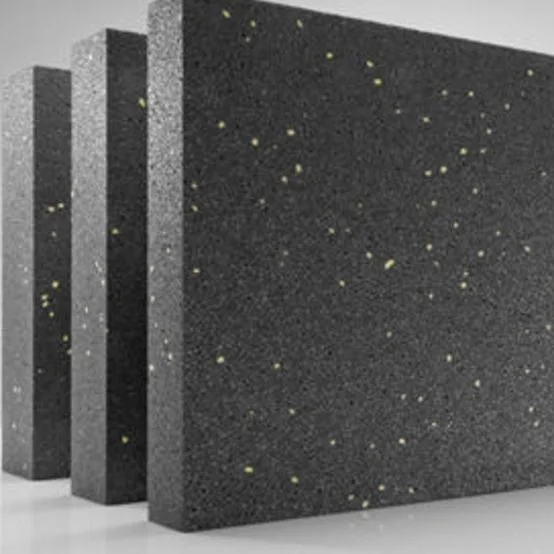

EPS keeps things warm or cool because of its special structure. It has tiny closed cells filled with air. These air pockets stop heat from moving easily. When special ingredients like graphite or carbon black are added during the bead-making process, EPS becomes even better at blocking heat.

For example, FGE-low thermal conductivity carbon polystyrene FGE material lowers heat flow in insulation boards. It also prevents static electricity and works well for heavy-duty uses.

For top-notch insulation in eco-friendly homes or big industrial projects, Graphite Polystyrene(Extrusion Method)–S-32 is a great choice. It combines excellent heat-blocking power with easy production for large-scale projects.

EPS Moisture Resistance and Durability

EPS doesn’t soak up water easily because of its closed-cell design. This makes it perfect for damp places or areas that sometimes get wet. Also, when EPS is made with fire-resistant features, like those meeting B1 or B2 fire safety rules, it lasts longer and stays safe in tough conditions.

The F-flame retardant grade has passed tests by the United States Safety Testing Laboratory (UL). It meets B2 standards for building materials, ensuring it lasts while keeping fire risks low.

Where Is EPS Used Across Industries?

EPS is crazy useful across tons of fields since it’s so darn flexible. In packaging, it’s top-notch for soaking up bumps and can be shaped into pretty much anything. Take the E-standard grade E-301—it’s perfect for keeping electronics, ceramics, fishing boxes, or fruit containers safe and sound. Plus, it’s light, so you’re not burning cash on shipping. In construction, EPS shines as the core of insulated panels or just as plain boards. It’s tough, stops heat in its tracks, and helps buildings cut down on energy costs while staying solid. And for stuff like drugs or food that’s gotta stay chilled? EPS boxes are the way to go. They keep things cold for a good long while without needing extra cooling gadgets, which makes them great for moving sensitive items.

Which Material Performs Better: EPS or Styrofoam?

Picking the right material for your HUASHENG project boils down to what you need and how you plan to use it. EPS and Styrofoam both have their strengths, but they shine in different ways. EPS is crazy versatile, easy to shape, and can be tweaked for toughness or insulation. Styrofoam’s got its own perks, but it’s not always the best fit. Let’s break down how they stack up for your project’s goals, budget, and eco-friendly vibe.

Matching Project Needs

Figuring out whether EPS or Styrofoam fits your HUASHENG project starts with what you’re aiming for. Need something tough? EPS can keep up with Styrofoam’s strength by using denser beads. It’s also super easy to mold into all kinds of shapes, which gives it an edge for custom work like packaging or construction. Throw in some graphite or carbon black, like HUASHENG’s FGE-graphite polystyrene, and EPS traps heat just as well as Styrofoam—sometimes even better—while staying lighter on your budget.

Thinking About Costs

When it comes to long-term savings, EPS pulls ahead. HUASHENG’s materials use less energy to produce, cure quickly, and cut down on waste. That adds up to real savings over time. Plus, EPS works like a charm with automated machines, letting you tweak bead density to suit the job without needing to swap out equipment. Styrofoam, on the other hand, can hit your wallet harder and isn’t as flexible for big projects.

Staying Green and Compliant

Going eco-friendly matters, and EPS makes it easier. Its bead structure means it’s a breeze to recycle, with plenty of programs out there to handle it. HUASHENG’s FHE-N-HBCD, for instance, uses flame retardants that play nice with strict EU environmental rules, making it a solid pick for green projects. Since 2015, HUASHENG has leaned on top-notch European tech to churn out reliable EPS beads for things like sustainable homes, packaging, or cold chain logistics, keeping costs low and the planet happy.

FAQ

Q: Can foam polystyrene beads be reused after initial molding?

A: No. Once beads are expanded and shaped, they can’t go back to their original form. But EPS can often be recycled if local facilities are available.

Q: Is there a difference between black graphite-enhanced EPS and regular white EPS?

A: Yes. Graphite-enhanced EPS blocks heat better because graphite reflects infrared rays during production.

Q: Does higher density always mean better performance?

A: Not always. Heavier beads are stronger, but lighter ones insulate better per weight. Choose based on what your project needs.