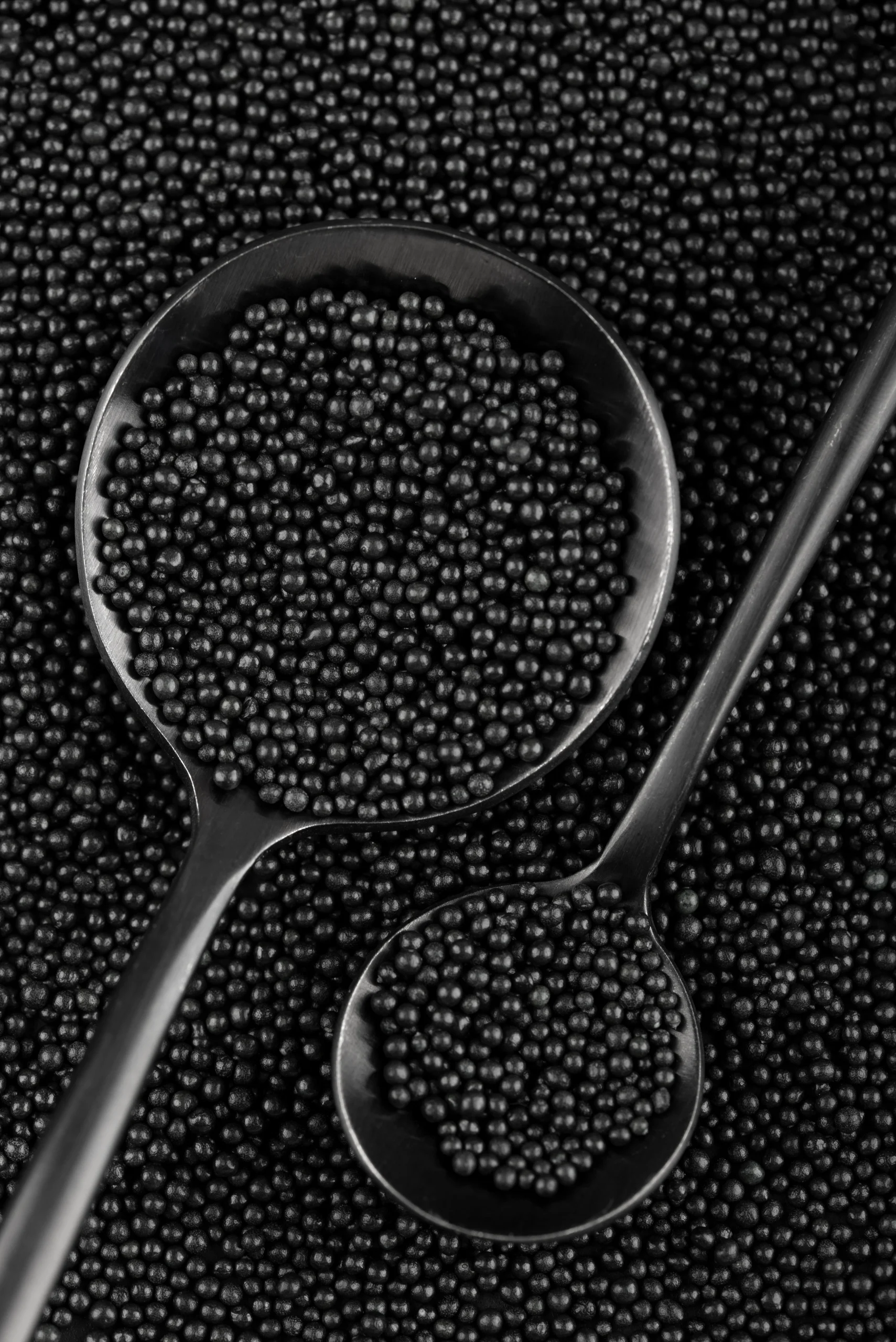

Expandable polystyrene beads are petite, airy plastic orbs. They blend polystyrene resin with a blowing agent, often pentane. When kissed by steam, these beads balloon up to 50 times their starting size. This forms a closed-cell foam structure. The structure gifts EPS with stellar qualities for insulation, packaging, and construction. It boasts minimal heat flow and cushions impacts like a dream. The unique makeup of EPS beads sparks outstanding performance. To grasp their worth, sizing them up against other foam materials paints a vivid picture.

This exploration illuminates EPS’s brilliance. It also showcases its edge over rivals. Let’s plunge into how EPS shines and where it thrives.

EPS Beads Performance and Application

EPS beads are remarkably versatile. This versatility drives their widespread use across countless industries. Their exceptional properties form the foundation for diverse and growing applications. To grasp their significance, understanding both their performance and applications is key.

Performance

EPS beads dazzle with their sturdy yet featherlike nature. They hold their shape like steadfast guardians, shrug off moisture, and endure pressure with grace. HUASHENG, rooted in Lanzhou, taps local strengths to forge clever production lines. They harness top-tier EPS foaming wizardry and pinpoint testing tools. This ensures their products gleam with even density, resilience, and thermal shielding. The closed-cell design locks in warmth, fends off mold, and stands the test of time. These traits make EPS beads a chameleon across industries.

Application

EPS dances across diverse fields. It is used in construction for insulation panels and in packaging for fragile electronics. It also plays a role in cold-chain logistics, car parts, prefab structures, and earthquake-proof systems. HUASHENG crafts EPS varieties like standard, flame-retardant, and graphite-modified types. These cater to shipping, building, and protective packaging demands.

The adaptability of EPS makes it a beloved choice. Its uses keep blooming, fueled by its trusty performance.

Competitors to Expanded Polystyrene (EPS)

Expanded Polystyrene (EPS) foam is a nimble material thriving in insulation, packaging, and construction. Yet, it faces spirited competition from foams with distinct textures and practical charms.

- Polyurethane (PU) foam, for example, is supple and cradles items under strain. It glows in protective packaging. But it wilts faster than EPS in soggy settings and lacks enduring stamina.

- Extruded Polystyrene (XPS)foam, with its tightly knit closed-cell structure, boasts mighty compressive strength and fends off moisture better than EPS. This makes it a gem for below-ground insulation. It’s catch? A heftier price.

- Polyethylene (PE)foam shines in cushioning for packaging. It’s light as a breeze and soft as a whisper, but stumbles in heat resistance, curbing its insulation potential.

EPS sparkles with a harmonious mix of mechanical and thermal traits. It delivers robust insulation and featherlight strength at a gentler cost than XPS. While it may not match PU’s pliability, XPS’s toughness, or biodegradable foams’ green allure, EPS remains a steadfast pick. It suits projects craving steady thermal performance and affordability, especially in construction and packaging.

This harmony makes EPS a practical star. Let’s probe how it fares in strength and heat.

How Do These Foams Perform in Strength and Heat?

Expanded Polystyrene (EPS) foam radiates in durability, insulation, and cost-friendliness, standing tall against rivals like Polyurethane (PU) and Polyethylene (PE). HUASHENG’s cutting-edge production ensures EPS achieves flawless density and bolstered strength. Their graphite-modified FGE grade amps up load-bearing prowess while staying light as a cloud. Thanks to its closed-cell structure, EPS delivers top-notch R-values per inch. It rivals or outshines the insulation power of PU and PE foams. It demands less thickness and slimmer budgets. HUASHENG’s graphite-enhanced FGE grade also curbs radiant heat loss. This vastly boosts thermal retention for construction and packaging needs.

Sustainability fuels EPS’s charm. It aligns with growing eco-conscious tides. EPS production, especially for standard grades, sips less energy than PU or XPS, which guzzle intense heat or chemical curing. Recycled EPS beads meet REACH and ROHS standards. They can be reborn in production without losing their essence. This recyclability, paired with energy-thrifty manufacturing, crowns EPS as a greener contender. Its eco-friendly nature and cost-effectiveness at scale make EPS a wise choice for sprawling insulation and packaging projects.

EPS’s prowess and green credentials make it a standout. Its affordability for grand projects cements its appeal.

Is EPS Cost-Effective for Large-Scale Use?

Expanded Polystyrene (EPS) gleams as a wallet-friendly choice for massive projects. Its streamlined production and dependable supply chain fuel its affordability. EPS needs minimal post-expansion fuss. Swift molding, thrifty steam use, and simple tooling slash costs compared to Polyurethane (PU) or Polyethylene (PE) systems. HUASHENG’s localized expansion, backed by global polystyrene resin networks, ensures a steady flow for major ventures. This boosts EPS’s affordability and reliability. These factors make EPS a savvy pick for applications demanding performance and scalability.

EPS’s distinct qualities make it a hero for specific tasks. It outpaces rivals in key arenas. Unlike PU, which sags over time despite greater bounce, or PE, which lacks structural grit, HUASHENG’s E-standard EPS offers tight bead fusion and lasting vigor. This makes it ideal for molded cases needing rigidity and shock resistance. EPS panels, like the FHE-101 model, provide superb water resistance and shape stability across temperature swings. They’re a prime choice for exterior wall insulation. High-expansion EPS grades deliver strength without extra heft. This boosts fuel efficiency and payload capacity in vehicles and aircraft. They also meet rigorous safety standards.

EPS’s cost-effectiveness and performance make it a magnetic choice. Innovations in foam technology further amplify its potential.

What New Ideas Are Pushing Foam Tech Forward?

Recent leaps in foam technology have stretched the horizons of Expanded Polystyrene (EPS). HUASHENG leads the pack. Their EPS products hit B1 flame-retardant benchmarks. They offer enhanced heat and sound insulation, plus nimble anti-static properties. These upgrades open doors to new uses, like protective cases for electronics and sound-dampening barriers. HUASHENG’s digital twin lab, armed with material gene banks and process simulations, forecasts bead performance in varied settings with uncanny accuracy. This leaps past old-school testing methods. It ensures bespoke solutions for diverse demands.

Why Choose EPS for Advanced Applications

When picking EPS, its trailblazing features steer smart choices. HUASHENG’s flame-retardant EPS fits projects needing heightened fire safety, like electronics packaging or building insulation. For tasks craving superior sound or thermal shielding, such as auditoriums or energy-efficient structures, EPS’s boosted traits outshine rivals like PU or PE. The power to simulate performance via digital twin technology ensures EPS meets precise project needs. This makes it a versatile and trustworthy pick for modern construction, packaging, and niche industrial uses.

These innovations underscore EPS’s flexibility. Choosing the right foam hinges on grasping project demands.

Choosing Based on Project Needs

Picking the perfect foam rests on project goals. EPS shines with its unique strengths. If you seek lightweight, unyielding structures with superb heat resistance and eco-friendly perks, expandable polystyrene beads offer dazzling versatility. They thrive in construction, shipping, and more. Their balanced performance, affordability, and green credentials make them a prime choice for varied applications.

EPS’s adaptability ensures it meets diverse needs. Its strengths align with modern project demands, from insulation to protective packaging. Special design is allowable, welcome to contact HUASHENG!

FAQ

Q: Can EPS Beads Be Reused After Molding?

A: EPS beads can be reborn after molding if recycled and processed properly. Expanded Polystyrene is a thermoplastic material. It can be melted and reshaped into fresh products without losing core traits. The recycling process gathers used EPS, cleans it to remove impurities, and grinds or melts it into reusable pellets or beads.

Q: How Do I Pick Between Standard and Modified Beads?

A: Choosing between standard and modified EPS beads hinges on your project’s unique needs. Weigh performance demands, environmental conditions, and budget. Standard beads suit general tasks, while modified beads, like HUASHENG’s graphite-enhanced types, offer boosted strength or insulation for specialized roles.

Q: Are There Health Risks with EPS?

A: EPS is safe when crafted and used per industry standards. Its widespread use in food packaging, medical applications, and construction highlights its safety. Proper handling and disposal are crucial. If you have concerns about EPS in your project, consult manufacturers or safety experts to ensure compliance with regulations.