Polyethylene foam can support sustainable packaging goals when designed for recyclability, efficient material use, and compliant manufacturing. Through closed-loop recycling systems, additive-safe formulations, and energy-efficient extrusion processes, modern polyethylene foams can balance protection, lightweight performance, and reduced environmental impact. Innovations such as customized density structures, non-HBCD flame retardants, and digital optimization allow foam packaging to meet circular economy requirements while maintaining durability, safety, and cost efficiency across logistics, electronics, and industrial applications.

Why Is Polyethylene Foam Being Reconsidered in Sustainable Packaging Discussions?

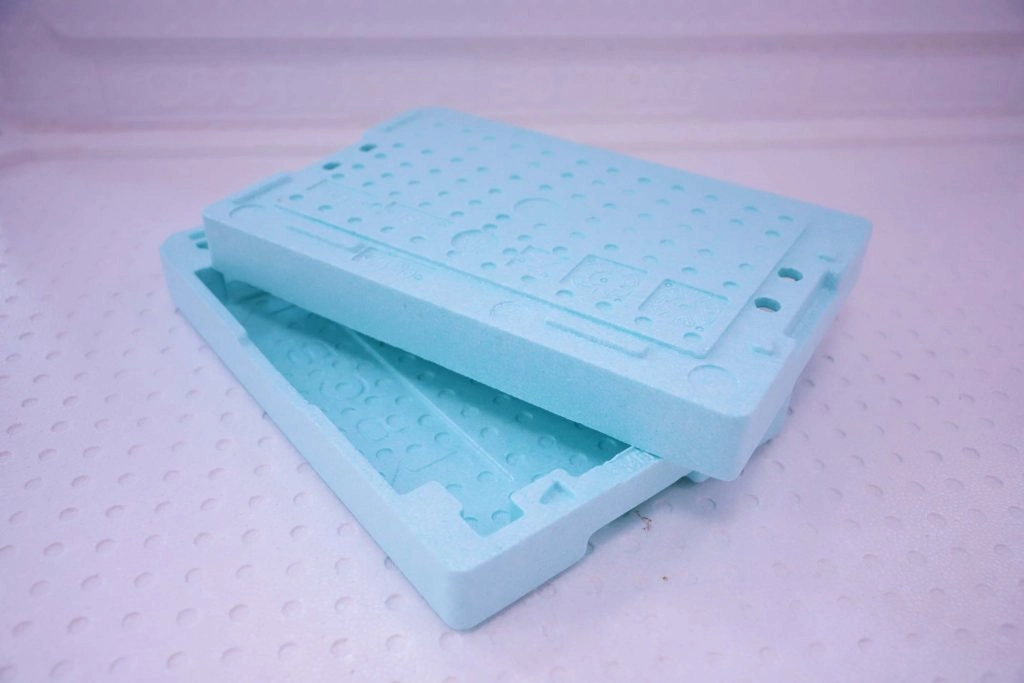

Polyethylene foam has remained valued for its lightweight, resilient, and shock-absorbing characteristics, making it a common choice in packing for electronics, automotive, and construction fields. However, with sustainability becoming a top selection criterion, traditional materials like polyethylene foam face strict scrutiny. The main worry comes from its past link with one-time uses and limited reuse in conventional municipal systems.

As circular economy ways grow strong, industries are shifting focus from just functional materials to those that also shoulder natural accountability. Packaging workers and sustainability advocates now check old foams not only on protective performance but also on life cycle impact.

How Does Polyethylene Foam Fit Within Circular Economy Models?

Polyethylene foam finds more place in closed-loop reuse systems. Special take-back plans and press tech let used foams gather, make thick, and turn into new work items. HUASHENG reuses 300,000 tons of EPS each year, saveing 1,500,000 tons of crude and 1,200,000 tons of carbon dioxide. This shows how big reuse can greatly reduce raw material use and greenhouse gas emissions.

Building polyethylene foam for reuse starts with picking additive-free or low-toxicity types that comply with local recycling infrastructure. Materials like REPS products have great impact resistance and toughness. The original plan of their study and development aimed to improve the use of traditional EPS in packaging material projects. REPS foams, when made through physical methods instead of chemical ones, naturally create fewer side effects and can be reused by machines with less nature burden.

What Are the Key Characteristics That Make a Foam Material Sustainable Without Compromising Function?

To count as a green foam item, it must give results that match with usual choices while causing nature harm across its life. Essential characteristics include mechanical durability, thermal stability, low density for reduced material usage, and recyclability. REPS products have great impact resistance and toughness, which makes them suitable for high-value protective uses.

The development of extrusion customized REPS, which makes tailored density and structure, helps makers reduce material mass without harm to compromising or insulation. These new ideas match green aims by using just enough materials to reach the planned work while raising reuse at the end of life.

How Can You Ensure Your Foam Selection Meets Environmental Compliance Standards?

To match foam selection with global environmental goals, certifications like REACH, RoHS, and EPR compliance must come first. Use non-HBCD flame retardants, in line with EU REACH, ROHS standards, is a specification met by HUASHENG’s FGH and FHE series foams. These materials are manufactured without halogenated flame retardants or heavy metals, ensuring compatibility with green procurement requirements.

Besides, the use of non-HBCD-based flame retardants such as those in the FHE-N-HBCD flame retardant grade, shows how modern chemistry can achieve both fire performance and recyclability. Compliance should be validated through third-party testing—HUASHENG has received REACH and RoHS certification for its R-EPS products—to ensure full transparency across the value chain.

What Role Does Process Innovation Play in Creating Eco-Conscious Foam Solutions?

Modern extrusion technology plays a critical role in raising sustainability of polyethylene foam. By better control over bead size, density spread, and expansion rates during making, manufacturers can reduce raw material input without sacrificing performance. REPS pre-foaming and molding technology offers significant production efficiencies, reducing total molding energy consumption by over 20% and increasing molding cycle efficiency by more than 50%.

Customization at the extrusion stage enables targeted application of material—more where structural support is needed, less where flexibility suffices—thereby reducing waste at both production and application levels.

Energy-efficient manufacturing is another cornerstone of sustainability. Through its original “three-circulation” production system, it achieves a recycling rate of over 95% for waste and reduces production energy consumption by 30%. Process innovation not only helps reduce operational carbon footprints but also enhances the ROI on sustainable packaging investments.

How Do You Balance Customization With Sustainability Targets?

Precise customization can be a powerful driver of sustainable development. Modular mold systems enable manufacturers to produce the precise quantities and sizes required for specific products, avoiding scraps and inventory buildup. In addition, digital modeling tools can simulate protective performance under various conditions, allowing engineers to optimize the geometry of foam materials before creating physical molds.

Custom making can also be carried out based on set works to reach build fine or full lightweight. This freedom makes sure even highly specialized packing plans—like for electronics or medical tools—reach without green harm.

Why Should You Consider HUASHENG as Your Partner for Sustainable Packaging Materials?

If the organization places both results top and nature care in packaging materials, HUASHENG stands as a global leading producer that focuses on EPS foam goods of top reused waste. Our promise to new ideas shines clearly through our own REPS tech platform, which features recyclable foams produced via clean manufacturing systems.

HUASHENG’s product portfolio includes better graphite-modified and flame-retardant foams that meet strict global standards like REACH and RoHS. graphite flame retardant grade-FGH-N-HBCD uses no-HBCD flame retardants, which meet EU REACH, ROHS standards. When the polymer forms by hanging join, the functional material graphite or carbon black is added to make the polystyrene polymer have functional properties.

Our vertically integrated production model—from raw material synthesis to finished form—enables complete control over quality and sustainability metrics. By working with HUASHENG, you gain access to a full suite of engineering services, including digital modeling, tooling customization, and ESG-compliant documentation.

Whether you’re designing thermal insulation for buildings or impact-resistant packaging for electronics, HUASHENG provides not only materials but also strategic insight to help your organization meet evolving regulatory and customer expectations.

FAQs

Q: Can polyethylene foam be recycled in standard municipal systems?

A: In many places, it can be reused through special gather plans, but not always curbside; check local reuse rules.

Q: How does graphite flame retardant improve fire safety without harming recyclability?

A: It raises heat fight while skipping halogen mixes that hard reuse steps.

Q: What makes extrusion-customized foams more sustainable than standard blocks?

A: They build best for set uses. This cuts extra items and waste during the making and packing plan.