استبدل سترة عادية مع سترة أسفل عالية التقنية وستشعر على الفور أكثر دفئا وأخفف وزنا وأكثر أمانا. تعكس هذه القفزة في علم المواد ثورة هادئة في عزل المباني. الجرافيت EPS ، أو الجرافيت بوليستيرين (GPS) ، يعيد تعريف السلامة وكفاءة الطاقة في البناء. على عكس الرغوة التقليدية ، يجمع بين مقاومة الحريق والمتانة والتصميم الصديق للبيئة ، مما يوفر للمبنيين والمهندسين المعماريين خيارًا أكثر ذكاءً. دعونا نغوص في سبب تحويل مواد عزل البناء في جميع أنحاء العالم.

حماية متفوقة من الحريق ما وراء مضادات اللهب التقليدية

عندما يختار البناء والمهندسون المعماريون مواد عزل البناء ، تأتي السلامة من الحريق في المقام الأول. رغوة وقف اللهب القديمة عملت بشكل جيد لسنوات عديدة. لكنهم لديهم مشاكل سرية يمكن أن تضر الثقة مع مرور الوقت. ومع ذلك ، فإن الجرافيت البوليستيرين (GPS) يدخل مع الصفات الداخلية التي تجاوز هذه القضايا. كواحد من أعلى صانعي EPS ، يعطي HUASHENG EPS المعزز بالجرافيت. يحدد مستوى جديد للحراس في المنازل وأماكن العمل والنباتات.

الحد من المضافات

تعتمد العديد من الرغوة التقليدية المضادة للشعلة على المضافات الكيميائية المختلطة في المادة أثناء الإنتاج. هذه المضافات تعمل عن طريق إبطاء اللهب عندما تضرب الحرارة. ولكن مع مرور الوقت، يمكن أن تنهار. التعرض للرطوبة أو الأشعة فوق البنفسجية يضعف تأثيرها. في اختبارات العالم الحقيقي، تفقد بعض الرغوة ما يصل إلى 20٪ من مقاومتها للحريق بعد خمس سنوات فقط. وهذا يعني أن ما يبدأ كخيار آمن قد لا يبقى بهذه الطريقة. البناء الذين يستخدمون هذه المواد يخاطرون باستبدالات مكلفة في المستقبل. عزل الجرافيت البولي ستيرين يتجنب هذا الفخ تمامًا. لا’ t تعتمد على المواد الكيميائية العابرة. بدلًا من ذلك ، تخلق جزيئات الجرافيت المضمنة في الرغوة حاجزًا طبيعيًا ضد انتشار الحريق.

مقاومة الحريق الجوهرية للجرافيت

الجرافيت تعزيز EPS يجلب مقاومة الحريق مباشرة في هيكلها الأساسي. تعكس جزيئات الجرافيت الحرارة وتشكل طبقة من الفحم عند تعرضها للنار. هذه الطبقة تعمل مثل درع، ومنع اللهب من اختراق أعمق. هواشنغ’ على سبيل المثال ، تحقق لوحات الجرافيت الصف S تصنيف حريق الفئة B1 بموجب معايير GB8624-2012. إنها تطفئ نفسها بسرعة، وغالباً في غضون ثوان من إزالة اللهب. على عكس الرغوة التقليدية التي قد تتقطر أو تذوب ، وتنتشر النار أكثر ، يحتفظ الجرافيت البوليستيرين (GPS) بشكله. في المحاكاة المختبرية لحرائق المباني، خفض لوحة العزل EPS الجرافيت انتشار اللهب بنسبة 40٪ مقارنة بالخيارات القياسية. وهذا يجعلها مثالية للمناطق عالية الخطورة مثل الجدران في المباني متعددة الطوابق.

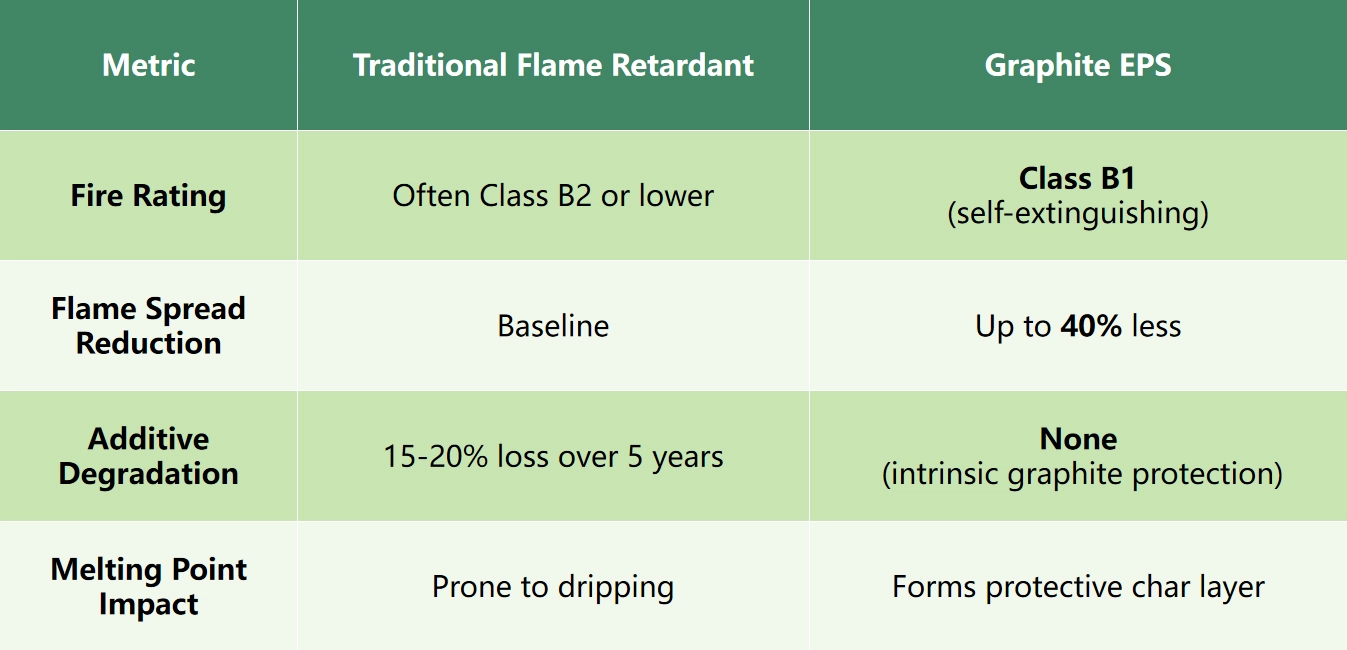

مع هذا الأساس في الاعتبار، الأرقام تحكي القصة الكاملة. مقارنة المقاييس الرئيسية تسلط الضوء على سبب تركيز مصنعي EPS مثل HUASHENG على الجرافيت على الطرق القديمة.

نظرة على مقاييس الأداء الرئيسية

لاتخاذ خيارات مستنيرة، يحتاج البناء إلى بيانات صلبة. إليك جدول مقارنة سريع بين الرغوة التقليدية المضادة للشعلة و EPS المحسنة بالجرافيت:

تأتي هذه الأرقام من اختبارات الصناعة ، مما يظهر عزل الجرافيت البوليستيرين ’ الحافة. للاحتياجات المخصصة للرغوة EPS ، تخصص HUASHENG هذه الألواح لتتناسب مع متطلبات المشروع المحددة ، مما يضمن أن كل قطعة توفر أعلى درجة من السلامة من الحرائق.

تحقيق وفورات طاقة أكبر على المدى الطويل

السلامة من الحرائق تحصل على إشعار ، ولكن توفير الطاقة يبقي الفواتير منخفضة على مبنى ’ أيام. تغطي الرغوة القديمة الحرارة بشكل جيد في البداية ، لكنها غالبا ما تفقد القوة. الجرافيت EPS لوحة العزل تحول ذلك مع التحكم في الحرارة أفضل. مع استمرار صانعي EPS في إصلاح بضائعهم ، فإن إضافة الجرافيت إلى أغطية المباني تجلب توفيرًا دائمًا في الطاقة.

- علم العزل العاكسيعمل الجرافيت عن طريق ارتداد الأشعة الدافئة ، مثل الزجاج الذي يرسل الضوء إلى الوراء. في الجرافيت البوليستيرين (GPS) ، قطع الجرافيت الصغيرة تنتشر الموجات الساخنة. وهذا ينخفض تدفق الحرارة إلى حوالي 0.033 واط / (م · ك). هذا أفضل بنسبة 15-20٪ من العديد من الرغوة القديمة ، والتي تبقى عند 0.038-0.040 واط / (م · ك). لذلك يترك الدفء أقل في الأوقات الباردة أو يأتي خلال الأيام الحارة. بالنسبة لمنزل عادي يبلغ مساحته 2000 قدم مربع ، فإن التغيير إلى EPS المعزز بالجرافيت يمكن أن يقلل من الاحتياجات الحرارية بنسبة 10-15٪. يلاحظ العمال هذا في الوظائف الحقيقية - يبقى عزل الجرافيت البوليستيرين حتى في الطقس القاسي.

- الاتساق في الأداء مع مرور الوقتالرغوة القديمة تقطع أو تمتص بالرطوبة ، وتسقط ما يصل إلى 10٪ من قوة الغطاء بعد عشر سنوات. ولكن الجرافيت EPS العزل لوحة تحارب هذا. بناء الخلية المغلقة يمنع المياه. والجرافيت يحتفظ بقوة المواد. في فحوصات الشيخوخة ، احتفظت لوحات الجرافيت من الدرجة S بنسبة 95٪ من مهاراتها الحرارية بعد 10 سنوات من الاستخدام المزيف. هذه الطريقة الثابتة تناسب المباني طويلة الأمد مثل بقع المتاجر أو الشقق.

- التأثير المباشر على فواتير الطاقةتخيل مبنى تجاري يحتوي على 50،000 قدم مربع من الجدران المعزولة. قد يوفر استخدام الرغوة التقليدية 5000 دولار سنوياً في الطاقة في البداية. ولكن مع ارتداء ، ينخفض هذا إلى 4000 دولار بعد خمس سنوات. يبدأ الجرافيت البوليستيرين (GPS) عند 6000 دولار في توفير ويبقى ثابتاً. هذا يضيف ما يصل إلى 10،000 دولار أكثر على مدى عشر سنوات. الحقائق الحقيقية من الكهرباء في الاتحاد الأوروبي تؤكد ذلك - كانت المباني ذات عزل الجرافيت البوليستيرين لديها فواتير أقل بنسبة 12٪ في المتوسط. بالنسبة للعمال ، يعني هذا أن المالكين سعداء وأقل شكاوى حول الفواتير العالية.

تقديم قيمة مادية أقوى

الطاقة ومزايا الحريق رائعة، ولكن القيمة تربط كل شيء مع بعضها البعض. يوازن EPS المعزز بالجرافيت التكاليف المبكرة مع الفوائد مدى الحياة ، مما يجعله رائعًا في مواد عزل البناء. مصنعي EPS مثل منتجات الحرف HUASHENG التي توفر المزيد من دون كسر الميزانيات.

- توازن التكلفة والأداء: للوهلة الأولى ، قد تكلف لوحة العزل EPS الجرافيت 10-15٪ أكثر من الرغوة الأساسية. ولكن عامل في طول العمر، ويعود ثمنه. انخفاض استخدام الطاقة وحدها يسترد الفرق في 2-3 سنوات لمعظم المشاريع. بالإضافة إلى ذلك ، فإن التثبيت بسيط - تقلل الألواح الخفيفة الوزن من وقت العمل بنسبة 20٪. تقدم HUASHENG خيارات رغوة EPS مخصصة ، مما يتيح للبناة طلب أحجام دقيقة لتقليل النفايات. وهذه الكفاءة تبقي المشاريع على المسار الصحيح وبدون الميزانية.

- ميزة المتانة والقوة: الجرافيت البوليستيرين (GPS) يفتخر كثافة 15-35 كيلوغرام / متر مكعب بعد التوسع ، مما يوفر قوة ضغط صلبة. تتحمل 150-200 كيلوباسكال دون تشوه ، وهي أفضل بكثير من الرغوة التقليدية الناعمة التي تترك مكانها عند 100 كيلوباسكال. في البناء ، يعني هذا أن عزل الجرافيت البوليستيرين يدعم الأحمال في الأرضيات أو الأسطح دون التشقق. هواشنغ’ لوحات الجرافيت الصف S تلمع هنا ، مصبوبة لتناسب الدقة في التطبيقات المطلوبة مثل الغطاء أو التعبئة والتغليف. الاستدامة تؤدي بطبيعة الحال إلى الاستدامة. اختيار المواد التي تدوم يقلل من التأثير البيئي مع مرور الوقت.

- خيار مستدام للبناء الحديثيستخدم EPS المحسن بالجرافيت مواد خام أقل لنفس تأثير العزل - أقل بنسبة تصل إلى 30٪ في بعض الحالات. هذا’ يمكن إعادة تدويرها أيضًا ، بما يتناسب مع أهداف الاقتصاد الدائري. تشدد هواشنغ على التصنيع الأخضر ، وإعادة تدوير أكثر من 95٪ من النفايات في الإنتاج. بالنسبة للمبنين الواعيين بالبيئة ، فإن هذا يجعل لوحة عزل الجرافيت EPS فائزا واضحا في مواد عزل البناء. تحصل المشاريع على شهادات خضراء بسهولة مع هذه الميزات.

فهم تصنيعها البسيط والفعال

وراء الفوائد تكمن عملية إنتاج نظيفة. تتضمن الرغوة التقليدية إضافات فوضوية ، ولكن الجرافيت EPS يأخذ مسارًا مبسطًا. مع ابتكار مصنعي EPS ، تقوم HUASHENG بتحسين طرق الجرافيت الموثوق به (GPS).

- دور التطرد المتقدم: يبدأ التصنيع بثقب حبات البوليستيرين المضغوطة بالجرافيت. آلات الضغط العالي تسخين وتشكيل المزيج، وخلق ورق رغوة موحدة. هذه الخطوة تضمن انتشار جزيئات الجرافيت بشكل متساو، على عكس الطرق التقليدية المختلطة يدويا التي تخاطر بالتجمع. هواشنغ’ عملية S تحقق نسبة توسع 50-70 مرة للحرز الأكبر، وإنتاج لوحات خفيفة الوزن ولكن كثيفة.

- ضمان التوزيع الموحد: في المراحل النهائية، التبريد وقطع قفل في الهيكل. أجهزة الاستشعار المتقدمة تراقب الكثافة، وتضرب تلك البقعة الحلوة 15-35 كيلوغرام / متر مكعب باستمرار. هذا يؤدي إلى عزل البوليستيرين الجرافيت خالي من الفراغ أو المناطق الضعيفة. بالنسبة للرغوة EPS المخصصة ، تعدل HUASHENG المعلمات عند الطلب ، وتقديم حلول مصممة خصيصاً. يحصل البناء على مواد تثبيت بسلاسة وأداء كما وعد.

استنتاج

الجرافيت EPS يظهر بوضوح مزاياه الشاملة على الرغوة التقليدية المضادة للحريق من حيث السلامة من الحريق وكفاءة الطاقة والقيمة طويلة الأجل والتقدم التكنولوجي. إنه الخيار الحتمي لاحتياجات البناء المستقبلية.

استكشاف هواشنغ قم بتصميم EPS الجرافيتي اليوم وبناء أساس متين وموثوق به لمشروعك القادم. اتصل بنا الآن على info@r-eps.com لمعرفة المزيد عن لوحات العزل EPS الجرافيت وخيارات رغوة EPS المخصصة ، ولنعمل معا لبناء مساحات أكثر أمانا وخضرة.