ويحدد اختيار مورد مناسب لخدمات البيئة العامة نتائج المشروع ويؤثر على كفاءة الميزانية ومتانة المنتج الممتدة. المواد متعددة الاستخدامات البوليستيرين الموسع تخدم (EPS) صناعات متعددة تشمل البناء والتغليف والتطبيقات المتخصصة التي تحتاج إلى مواصفات أداء معينة. تتطلب عملية اختيار مورد EPS تقييمًا كاملًا وأسئلة استفسار محددة لأن العديد من مقدمي السوق يقدمون مستويات خدمة مختلفة وجودة المنتج ومعرفة متخصصة. يوفر الدليل التالي جميع المعلومات اللازمة لمساعدتك على تقييم موردي EPS من خلال معايير التقييم الأساسية وأسئلة التقييم الحيوية.

العوامل الرئيسية التي يجب تقييمها عند اختيار مورد EPS

يجب فهم معايير تقييم الموردين قبل البدء في الاتصال بالموردين المحتملين.

جودة المنتج والاتساق

يضمن موردو EPS الموثوقون جودة منتج متسقة عبر الدفعات ، والحفاظ على كثافة مستقرة وأداء واستقرار الأبعاد. حجم الخرز الموحد وسيولة الرغوة هي أساسية ، مدعومة بمواصفات تقنية شاملة ووثائق مراقبة الجودة.

الامتثال لمعايير الصناعة والشهادات

تحتاج منتجات EPS إلى اتباع لوائح الصناعة لتحقيق متطلبات السلامة والأداء. حصلت درجة F-flame retardant على شهادة UL من مختبر اختبار السلامة في الولايات المتحدة برقم شهادة الوثيقة E360952. يحتاج الموردون إلى إظهار أدلة على الوفاء بالمعايير التي تشمل رغوة البولي ستيرين المصبوبة (GB / T10801.1-2002) وتصنيف أداء الاحتراق لمواد البناء والمنتجات (GB8624-2012).

توفر الدعم الفني وخدمة ما بعد البيع

أبرز موردي EPS يتميزون بقدرات تقنية متفوقة ودعم مستمر ، يقدمون مساعدة مفصلة من اختيار المنتج إلى التطبيق ، وإصلاح المشاكل السريع ، وخدمة العملاء الاستجابة لمسائل الإنتاج.

أنواع منتجات EPS التي يجب أن تعرفها

يعتمد اختيار منتج EPS المناسب على فهم درجات EPS المختلفة واستخداماتها المقصودة.

الصف المشترك EPS

الصف 1 E-معيار EPS مثالي لمختلف التطبيقات ، مما يقدم رغوة سريعة ، وأبعاد مستقرة ، وقوة عالية ، والحد الأدنى من التقلص. إنها تناسب تشكيل الفراغ التلقائي ، والدفع الكهربائي ، وأنظمة الصحافة الهيدروليكية ، والتي تستخدم في التعبئة والتغليف الكهربائية والعزل الحراري وعوائم الصيد والحرف اليدوية والديكور والرغوة المفقودة.

مثبطة اللهب درجة EPS

تعتمد متطلبات السلامة من الحريق لبعض التطبيقات على درجات مضادة للشعلة التي تعمل كتدابير حماية أساسية. تتطلب معالجة درجة مُبطئ اللهب F فصل صارم عن المواد غير المُبطئ اللهب لأن أي اتصال مع EPS العادي سيقلل من فعالية مُبطئ اللهب. تظهر المنتجات خصائص مضادة للشعلة الفعالة التي تلبي متطلبات معيار B2 لمواد البناء.

الجرافيت درجة EPS

يوفر الـ EPS المعزز بالجرافيت (FGE-polystyrene الجرافيت) عزل حراري وصوتي متفوق مقارنة بالـ EPS القياسي. يتم إنتاجها عن طريق البوليمر المعلق ، ويتضمن الجرافيت لتقليل الموصلات الحراري ، وهو مثالي للبناء عالي الكثافة والتطبيقات الصناعية فوق 18 كيلوغرام / م3.

حماية البيئة درجة EPS

وتركز درجات حماية البيئة على تلبية الحاجة المتزايدة إلى الممارسات المستدامة. تستخدم المنتجات مضادات اللهب غير HBCD التي تتبع معايير الاتحاد الأوروبي REACH و ROHS لتحقيق أداء مضادات اللهب مستوى B1. تتميز المنتجات بخرز موحدة وسرعة الرغوة السريعة وخصائص الالتصاق القوية وقوة ممتازة ومستويات صلابة عالية.

الكربون الأسود درجة EPS

الكربون الأسود تعزيز EPS (FGE البوليستيرين الأسود) تقدم خصائص متفوقة مضادة للستاتيك ومكافحة الشيخوخة، مثالية للمكونات الكهربائية الواقية من الأشعة فوق البنفسجية والتغليف الأسود الدائم.

حلول REPS المخصصة

يقوم الموردون الرائدون بإنشاء منتجات متخصصة لحالات استخدام معينة. تسمح عملية البحث والتطوير والإنتاج وفقا لاحتياجات العملاء للموردين بإنشاء درجات مخصصة تلبي متطلبات أداء محددة من خلال صيغ مصممة خصيصا ومعلمات المعالجة.

أسئلة مهمة لتسأل موردك EPS

تتطلب عملية تقييم الموردين الاستجواب المناسب لتحديد قدراتهم ومطابقة عروضهم مع احتياجاتك.

ما هي درجات EPS التي تقدمها وكيف تختلف؟

يعتمد اختيار الدرجة المناسبة على المعرفة الكاملة بالمنتجات التي يقدمها المورد. يجب على المورد الذي يوفر خطوط منتجات كاملة أن يكون لديه مادة خفيفة إضافية من الدرجة المشتركة P وصف النماذج الأولية B-Rapid ومواد قياسية E ومواد مقاومة للشعلة من الدرجة F ومواد مقاومة للشعلة من الدرجة FB ومواد مقاومة للشعلة من الدرجة FS ومواد مقاومة للشعلة من الدرجة FSH-الأوروبية ومواد مقاومة للشعلة من الدرجة الجرافيت مع FGE-الجرافيت بوليستيرين (طريقة التعليق) و S-33 الجرافيت بوليستيرين (طريقة البثق) و S-32 الجرافيت بوليستيرين (طريقة البثق).

هل يمكنك تقديم وثائق حول اختبار المنتج وشهادته؟

تخدم عمليات الاختبار والشهادة التي تتحقق من أداء المنتج كدليل على موثوقية الموردين. يجب على المورد تقديم وثائق كاملة تتضمن تقارير الاختبار إلى جانب أرقام الشهادة وإثبات الامتثال لمعايير الصناعة المعمول بها.

ما هو وقت التسليم وقدرتك على التسليم؟

تمكن معرفة أوقات التسليم الشركات من إنشاء جداول إنتاج أفضل والحفاظ على مراقبة المخزون المناسبة. اسأل عن فترات التسليم النموذجية وخيارات التسليم السريع وتأكد من أن المورد يحافظ على أداء التسليم المستقر لكميات الطلب المختلفة.

هل تقدم الدعم لتطبيق المنتج أو المعالجة؟

تظهر قدرات الدعم التقني للمورد قدرته على تقديم نتائج ناجحة للعملاء خلال دورة حياة المنتج. يجب على المورد تقديم توجيهات التطبيق وتوصيات المعالجة ودعم إصلاح المشاكل للعملاء من بداية إلى نهاية رحلة منتجهم.

كيف تتعامل مع مراقبة الجودة أثناء الإنتاج؟

تحافظ عمليات مراقبة الجودة على أداء المنتج على مستوى متسق. يجب على الشركة تقديم معلومات عن إجراءات الاختبار الخاصة بها وكذلك أنظمة تتبع الدفعات وطرق مراقبة العمليات الإحصائية ووثائق الجودة التي ترافق كل شحنة.

تقييم المورد’ قدرات التصنيع

تحدد قدرات التصنيع جودة المنتجات واتساقها وموثوقيتها في عمليات سلسلة التوريد.

القدرة الإنتاجية والقدرة على التوسع

تقييم ما إذا كان المورد يستطيع تلبية احتياجات حجم المنتج الحالية والمستقبلية. استثمرت هواشنغ ، وهي شركة رائدة في تطوير المنزل السلبي ، في معدات الطاردة الأوروبية ذات المسمار المزدوج في عام 2015 ، وعرضت التصنيع المتقدم وقدرة الإنتاج القابلة للتوسع.

مصادر المواد الخام واستقرار سلسلة التوريد

تساعد عملية فهم المكان الذي يحصل فيه الموردون على موادهم الخام على الحفاظ على سلاسل توريد مستقرة مع الحفاظ على معايير جودة المنتج. اسأل موردك عن اتصالاته التجارية وتفاصيل المواد واستراتيجيات النسخ الاحتياطي لمنع انقطاع الإمدادات.

الابتكار في تطوير المنتجات

المورد’ تنعكس القدرة على تلبية متطلبات السوق المتغيرة وخلق حلول مصممة خصيصا من خلال قدرات الابتكار. المورد’ يجب أن تظهر قدرات الابتكار الخاصة بالشركة الإنفاق على البحث والتطوير وإطلاق منتجات جديدة وقدرات الشراكة التقنية.

شفافية التسعير والاعتبارات المتعلقة بالتكاليف على المدى الطويل

هيكل التسعير وعناصر التكلفة للمنتج تجاوز تكلفة الشراء الأولى.

تقسيم التكلفة لمنتجات EPS

ويتضمن الطلب تفصيلاً مفصلاً لجميع التكاليف بما في ذلك مصاريف المواد ورسوم المعالجة والرسوم الإضافية. ويصبح تقييم مقترحات القيمة وتحديد إمكانات تحسين التكلفة ممكنا من خلال فهم جميع مكونات التكلفة.

خصومات الحجم وشروط العقد

تقييم هيكل التسعير بناء على الحجم وتقييم مزايا العقود طويلة الأجل وشروط الدفع. وتحدد هذه العناصر التكلفة الكاملة للملكية والاحتياجات المالية للتدفق النقدي.

التكاليف الخفية للانتباه إليها

وسيتأثر اقتصاد المشروع بتكاليف التعبئة والتغليف الخاصة ورسوم الشحن المعجلة ونفقات الدعم التقني ومتطلبات الطلب الدنيا.

موثوقية اللوجستيات والتسليم

يعتمد نجاح جداول الإنتاج على اللوجستيات الفعالة وأنظمة التسليم الموثوقة التي تساعد على تقليل مصاريف المخزون.

خيارات الشحن وأوقات الرصاص

تقييم جميع خيارات الشحن مع أوقات التسليم ومناطق الخدمة. وينبغي أن يركز تقييم القدرات اللوجستية على قدرتها على دعم الاحتياجات التشغيلية والوفاء بالتزامات خدمة العملاء.

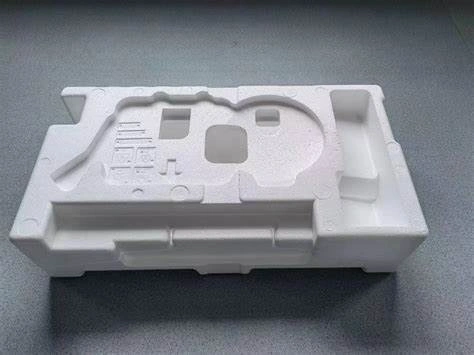

معايير التعبئة والتغليف للنقل الآمن

طرق التعبئة الصحيحة تحمي المنتجات من الضرر الذي يحدث أثناء عمليات الشحن. يجب إجراء تقييم مواد التعبئة والتغليف وأنظمة الحماية وطرق التعامل مع التسليم لضمان وصول المنتجات إلى وجهتها في حالة مثالية.

التعامل مع الطلبات العاجلة أو على نطاق واسع

تمكن قدرة الموردين على الوفاء بالطلبات العاجلة والأوامر الكبيرة الشركات من إنشاء خطط احتياطية لحالات الطوارئ وإدارة فترات الطلب العالي.

تقديم HUASHENG كمورد EPS موثوق

هواشنغ تبرز كمزود حلول كاملة لأنها تقدم مجموعة واسعة من المنتجات ومعرفة تقنية عميقة في عملية تقييم موردي EPS.

لمحة عامة عن HUASHENG’ مجموعة المنتجات

يوفر HUASHENG مجموعة كاملة من منتجات EPS التي تمتد عبر جميع فئات EPS الأساسية. تنتج الشركة P-مادة خفيفة إضافية و B-سريعة النماذج الأولية الصف و E-معيار المواد و F-مادة مضادة للشعلة و FB-مادة مضادة للشعلة الصف و FS-درجة مضادة للشعلة المواد ومواد FSH-الأوروبية القياسية ومواد FHE-N-HBCD ومواد FGH-N-HBCD ومواد FGH-N-HBCD ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE ومواد FGE.

استنتاج

تحدد معايير التقييم المتعددة عملية اختيار مورد EPS الصحيحة التي تشمل تقييم جودة المنتج وتقييم القدرة التقنية وتقييم القدرة التصنيعية وتقييم دعم الخدمة. يوفر الدليل أسئلة أساسية لتقييم قدرات الموردين التي ستساعدك على اختيار المورد الذي يدعم أهداف مشروعك وأهداف الأعمال المستقبلية. الخيار الأكثر فعالية من حيث التكلفة لا يوفر دائما أعلى قيمة لأنه يجب عليك تقييم إجمالي مصاريف الملكية وخدمات الموثوقية والدعم عند اختيار المورد النهائي الخاص بك.

الأسئلة الشائعة

Q1: ما الفرق بين درجة مضادة للشعلة والصف المشترك EPS؟

ج: يحتوي EPS من الدرجة المثبتة للشعلة على إضافات للسلامة من الحرائق ، والتي تلبي معايير UL (E360952). الصف المشترك EPS هو للتغليف القياسي ، مناسبة لمختلف آلات تشكيل.

س2: كيف يمكنك التحقق من جودة منتج مورد EPS؟

ج: تحقق من شهادات ISO 9001 / 14001 وتقارير اختبار الطرف الثالث وعمليات الإنتاج. استعراض استدعاءات، ردود الفعل من العملاء، وفحص العينات للعيوب.

Q3: هل يمكن لـ HUASHENG إنشاء حلول EPS مخصصة للتطبيقات المتخصصة؟

ج: نعم ، HUASHENG تصنع منتجات EPS مصممة خصيصا باستخدام المرافق المتقدمة والخبرة لتلبية احتياجات الأداء المحددة للتطبيقات المتخصصة.