إن K 2025 دوسلدورف تم لفها قبل أسابيع قليلة ، وجذب حشود من جميع أنحاء العالم لاستكشاف أحدث ما في البلاستيك والمطاط. أقيم معرض K 2025 من 8 إلى 15 أكتوبر في دوسلدورف بألمانيا، وجمع أكثر من 175،000 زائر من حوالي 160 دولة. مع عرض 3,257 عارضاً لأعمالهم ، كان الحدث مزدحماً بالطاقة. أخذت مواضيع مثل الاقتصاد الدائري والاستدامة مكانة مركزية ، خاصة في التعبئة والتغليف. كمنتج لمواد الرغوة EPS و R-EPS ، تركز HUASHENG New Materials على الحلول العملية للصناعات التي تواجه ضغوط بيئية. في هذه المدونة، نحن’ سوف تغطس في كيفية معالجة ابتكارات EPS من K 2025 للكفاءة والاستدامة وضغوط التكلفة في عالم التعبئة والتغليف. ما إذا كنت’ في مجال الخدمات اللوجستية أو التصنيع أو تصميم المنتجات ، يمكن لهذه الأفكار توجيه خطواتك التالية نحو حلول تغليف أفضل.

معالجة معضلة كفاءة التعبئة والتغليف

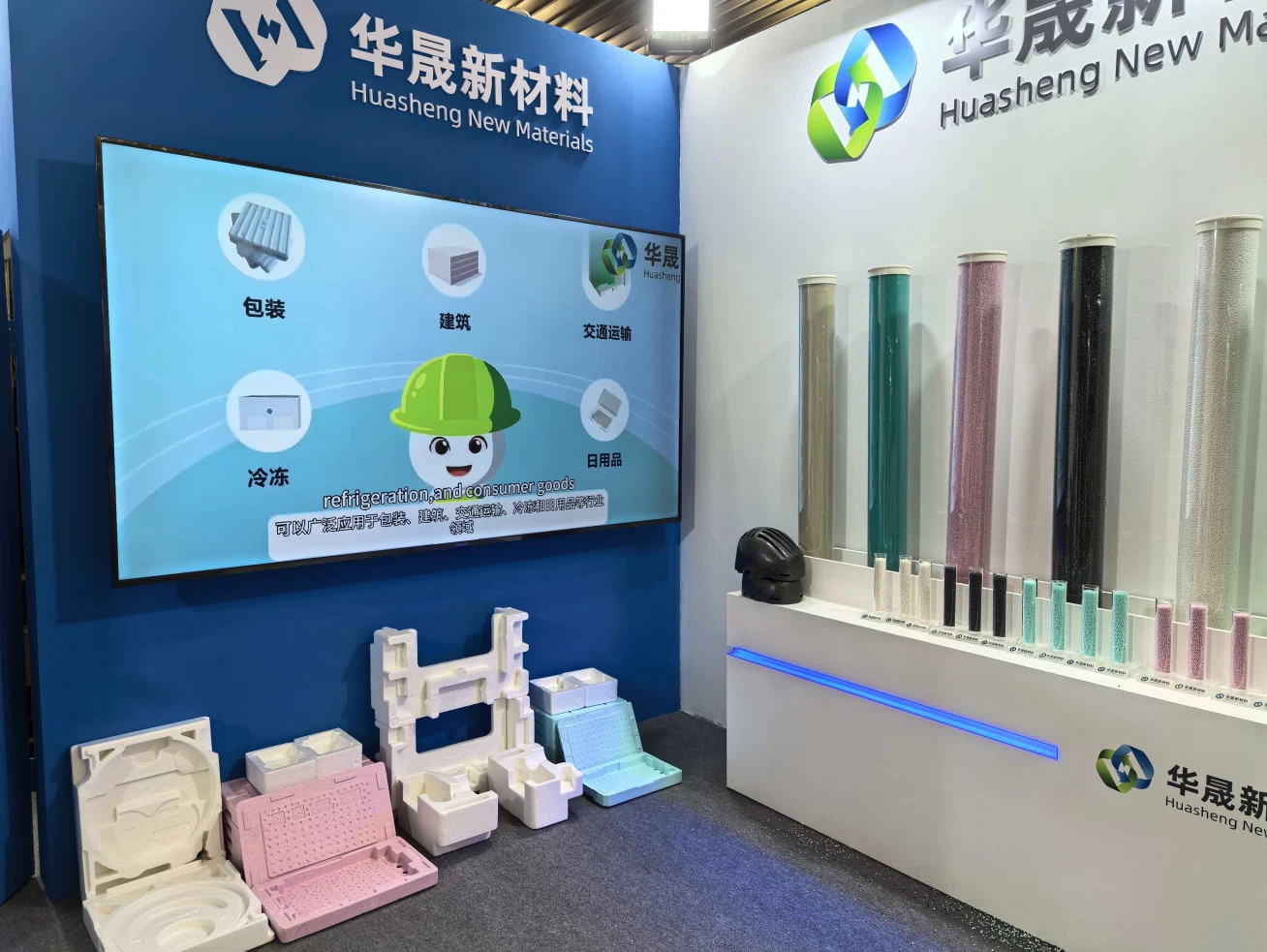

تعمل خطوط التعبئة والتغليف دون توقف في العديد من المصانع ، ولكن التباطؤ يمكن أن يؤدي إلى الأرباح. في K 2025 دوسلدورف، شارك الخبراء في كيفية تسريع المواد الجديدة دون التضحية بالجودة. عرضت HUASHENG New Materials حلول التعبئة والتغليف EPS التي تناسب بسلاسة في العمليات عالية السرعة. كان المعرض التجاري K مزدحمًا بعروض الرغوة التي تتشكل بسرعة وتحمل شكلها تحت الضغط. يبحث هذا القسم في طرق تعزيز الكفاءة ، بالاستناد إلى المحادثات الحقيقية في معرض K 2025.

متوافقة صب عالية السرعة

صب رغوة EPS بمعدلات أسرع تستخدم لتعني المزيد من العيوب أو أضعف المنتجات. ليس بعد الآن خلال K 2025 دوسلدورف ، رأينا رغوة EPS قابلة لإعادة التدوير من HUASHENG New Materials التي تعمل مع الآلات التي تعمل بسرعات تصل إلى 20٪ أعلى من الخيارات التقليدية. فكر في ذلك: في التعبئة والتغليف الإلكترونية ، حيث تحتاج علب الشاشات أو أجهزة الكمبيوتر المحمولة إلى تناسب دقيق ، يقلل هذا التوافق من أوقات الدورة.

لكن السرعة هي’ t فقط حول الآلة. هذا’ المواد’ حجم الخرز ومعدل التوسع الذي يجعل الفرق. هواشنغ’ s R-EPS ، مصنوع من المواد الخام المعاد تدويرها بنسبة 100 ٪ ، يتوسع بشكل متساو ، مما يقلل من المربى. قام الزوار في معرض K show 2025 باختبار العينات وشاهدوا مباشرة كيف يؤدي هذا إلى مسارات أكثر سلاسة. بالنسبة للصناعات مثل تصنيع العروض ، حيث تحمي التعبئة والتغليف EPS الشاشات الحساسة ، يعني هذا عدد أقل من الرفض وعملاء أكثر سعادة.

تحويل التروس قليلا، والكفاءة ترتبط أيضا بكيفية تعامل المواد مع وقت التوقف. لا أحد يريد الآلات خاملة بينما تنتظر الإصلاحات. هذا’ حيث تأتي الابتكارات من معرض K التجاري ، مع التركيز على المتانة والانتعاش السريع.

تقليل وقت التوقف والنفايات

ويضرب وقت التوقف بشكل قاسي - تظهر دراسات من قطاع البلاستيك أنه يمكن أن يكلف المصانع 50،000 دولار في الساعة في إنتاج ضائع. في K 2025 دوسلدورف، تحولت المناقشات إلى حلول التعبئة والتغليف eps التي تقلل من هذه الانقطاعات. HUASHENG New Materials أبرزت رغوة EPS القابلة لإعادة التدوير التي تقاوم التشقق أثناء التعامل ، مما يقلل من النفايات بنسبة تصل إلى 25٪. وبالعبارة الحقيقية، يعني ذلك إعادة تدوير أكثر من 95٪ من الخردة إلى الإنتاج، كما تفعل عملياتنا.

تخيل مستودع مزدحم: صناديق وسائد الرغوة للأجهزة تتراكم عالية. قد تتدهور المواد التقليدية تحت الوزن، مما يؤدي إلى إعادة التصنيع. ولكن في معرض K 2025، أظهرنا كيف تتحمل عبوات eps لدينا، مع اختبارات الضغط التي تظهر مرونة أفضل بنسبة 30٪. وهذا لا يقلل من النفايات فحسب بل يسهل أيضًا تدفقات العمل. بالطبع، تمتد الكفاءة إلى ما وراء أرضية المصنع. تغير المواد الخفيفة اللعبة للشحن ، وعروض معرض K التجاري دفعت تلك النقطة إلى المنزل مع بيانات عن توفير التكاليف.

خفيفة الوزن للوفورات اللوجستية

التعبئة الثقيلة تزيد بسرعة في تكاليف النقل. أسعار الوقود تتقلب، ولكن الأحمال الخفيفة دائما الفوز. عرضت K 2025 دوسلدورف محادثات حول عبوات إيبس خفيفة الوزن التي تحلق الأوقية دون فقدان الحماية. هواشنغ المواد الجديدة’ رغوة EPS القابلة لإعادة التدوير تزن أقل بنسبة 20٪ من البدائل القياسية ، ومع ذلك تؤثر الوسائد أيضًا. بالنسبة لشاحنة تحمل 1000 علبة تلفزيونية، يمكن أن يعني ذلك توفير 100 كيلوغرام - مما يترجم إلى انخفاض الانبعاثات والرسوم.

أظهرت بيانات K show 2025 كيف يدعم هذا النهج سلاسل التوريد العالمية. وشملت إحدى دراسات الحالة المقدمة شحن الإلكترونيات في الخارج: استخدام حلول التعبئة والتغليف الخفيفة الوزن خفض تكاليف الشحن بنسبة 12٪. هذا’ الرياضيات البسيطة. بالإضافة إلى ذلك ، مع قوة التراكم الأفضل ، يمكنك تناسب أكثر لكل منصة. هواشنغ’ منتجاتنا ، مثل حبات الرغوة الخاصة بنا للقوالب المخصصة ، تجعل هذا ممكنا مع الحفاظ على الاستدامة في الاعتبار.

هذه المكاسب في الكفاءة تهيئ الساحة لتحقيق مكاسب بيئية أكبر. وبينما تدفع الصناعات إلى ممارسات أخضر، أكد معرض K التجاري على كيفية سد المواد مثل رغوة EPS القابلة لإعادة التدوير الفجوة.

الاستجابة لدعوة الاستدامة

الاستدامة هي ’ t a buzzword anymore—it’ لا بد من. في K 2025 دوسلدورف ، أخذ الاقتصاد الدائري مكانة مركزية ، مع كشك مخصصة لإغلاق حلقات البلاستيك. ساهمت HUASHENG New Materials من خلال عرض خيارات التعبئة والتغليف المستدامة التي تعيد استخدام الموارد. كشف معرض K 2025 عن دفع قوي نحو المواد التي تدوم لفترة أطول وتتعاد تدويرها بسهولة. هنا، نحن’ سوف نستكشف الابتكارات التي تجعل التعبئة والتغليف EPS أكثر صديقة للبيئة، بناء على ما رأيناه وسمعناه.

الابتكارات في الحلول القابلة لإعادة التدوير

وتتراوح معدلات إعادة تدوير البلاستيك حوالي 9٪ على مستوى العالم ، ولكن EPS يمكن أن تفعل بشكل أفضل. تسلط K 2025 الضوء على رغوة EPS القابلة لإعادة التدوير التي تصل إلى 95٪ من الاسترداد في الأنظمة المسيطرة عليها. HUASHENG المواد الجديدة تقود مع R-EPS ، باستخدام الخرز المعاد تدويرها بنسبة 100٪ لإنشاء التعبئة والتغليف للبنود مثل لوحات OLED. هذا يقلل من احتياجات المواد العذراء بمقدار الثلث ، كما هو مبين في تجارب المصنع في معرض K التجاري. تتضمن حلول التعبئة والتغليف الخاصة بنا المضافات التي تحافظ على القوة عبر دورات متعددة. أحد أبرز النقاط في معرض K 2025: مناقشة حلقة حيث توقع الخبراء نمو السوق بنسبة 50٪ لهذه المواد بحلول عام 2030.

إلى جانب إعادة التدوير ، ظهرت الخيارات الحيوية باعتبارها تغييرات في اللعبة. وشعر الانتقال بطبيعة الحال، حيث ربطت المحادثات بين المواد القابلة لإعادة التدوير التقليدية والبدائل المستوحاة من الطبيعة.

استكشاف البدائل البيولوجية

تستمد الرغوة على أساس بيولوجي من النباتات ، مما يقلل من الاعتماد على النفط. في K 2025 ، شاركت HUASHENG New Materials التقدم في خلط العناصر الحيوية في EPS. على الرغم من أن مزيجاتنا ليست حيوية بالكامل بعد، إلا أنها تقلل من استخدام الوقود الأحفوري بنسبة 15-20٪. بالنسبة للتعبئة المستدامة في نقل الأغذية، يعني ذلك حواف قابلة للتسميد تتحلل بسرعة أكبر.

وتشمل نقاط البيانات انخفاضا بنسبة 25٪ في بصمة الكربون مقارنة بالصناعات الصناعية النقية. ولاحظ المشاركون من أوروبا كيف يتناسب هذا مع القوانين القادمة المتعلقة بالبلاستيك المستخدم مرة واحدة. هواشنغ’ يبقي نهج EPS التكاليف ثابتة، مما يجعل Bio-EPS قابلة للتطبيق لحلول التعبئة والتغليف اليومية.

كل هذا يتغذى في دورة أوسع. وتزدهر الاستدامة عندما تعود المواد إلى الوطن، وأعاد معرض K 2025 هذه الرسالة إلى الوطن بأمثلة حقيقية.

دعم الاقتصاد الدائري

الاقتصاد الدائري يحافظ على المواد في اللعب. أكد K 2025 على حلقات الإغلاق ، مع عرض HUASHENG New Materials كيفية إعادة تدوير رغوة EPS القابلة لإعادة التدوير 95٪ من النفايات. إنتاجنا يوفر الطاقة بنسبة 30٪ مقارنة بالطرق القديمة ، وتحويل الخردة إلى حبات طازجة للتغليف EPS.

وشملت المعارض عرضا حلقة: جمع، طحن، إصلاح. إحصائيات واحدة برزت - أكثر من 90٪ من لوحاتنا يتم إعادة استخدامها في بنايات جديدة. وهذا يدعم الصناعات التي تهدف إلى صفر النفايات. في معرض K التجاري، ناقش الشركاء توسيع نطاق هذا على الصعيد العالمي، وتوقع مليارات في المدخرات.

مع فرز الاستدامة ، فإن العقبة التالية هي التكاليف. K عرض 2025 أظهر كيف الأداء لا’ لا بد من كسر البنك.

التوازن بين ضغوط التكلفة والأداء

ارتفاع أسعار المواد الخام يضغط على الهوامش. ومع ذلك، في K 2025، ظهرت الحلول التي توفر القيمة دون اختصارات. HUASHENG المواد الجديدة ركزت على التعبئة والتغليف EPS التي تؤدي تحت قيود الميزانية. كشف معرض K التجاري عن بيانات عن الادخار على المدى الطويل ، مما تحول وجهات النظر من التكاليف الأولية إلى إجمالي الملكية.

- قيادة الاقتصاد الدائرينعود إلى نماذج الاقتصاد، ولكن مع عدسة التكلفة. رغوة EPS القابلة لإعادة التدوير من HUASHENG تخفض النفقات من خلال إعادة الاستخدام. في معرض K 2025، شاركنا كيف يقلل R-EPS من تكاليف المواد بنسبة 20٪ مع مرور الوقت. وتبلغ المصانع عن خفض رسوم التخلص إلى النصف مع إعادة تدوير بنسبة 95٪. هذا’ عملي: في الخدمات اللوجستية ، يتم إعادة توليد التعبئة والتغليف المرجع. مثال واحد من K 2025 - وفرت شركة 200،000 دولار سنويا عن طريق حلقة علب الرغوة.

- تعزيز أهداف الحياد الكربونيالأهداف الصافية الصفرية تظهر للعديد من الشركات. تسلط K 2025 الضوء على حلول التعبئة والتغليف EPS التي تخفض الانبعاثات. هواشنغ’ تستخدم التعبئة والتغليف المستدامة طاقة أقل بنسبة 30٪ في التصنيع ، مما يقلل من ثاني أكسيد الكربون بنسبة 25 طن لكل 100،000 وحدة. شملت العروض التجريبية في معرض K آلات حاسبة لبصمات القدم. التحول إلى رغوة EPS القابلة لإعادة التدوير يساعد الشركات على تحقيق أهداف 2030 دون إصلاحات ضخمة. هذا’ حول التقدم المستمر.

مسارك الاستراتيجي نحو الامتثال وما بعده

وتشدد القوانين على نفايات التعبئة والتغليف. لكن الامتثال يمكن أن يحفز الابتكار. في K 2025 ، حددت HUASHENG New Materials خطوات التعبئة والتغليف EPS التي تتجاوز الأساسيات. أكد معرض K التجاري على الكفاءة كمفتاح للبقاء في المقدمة.

- كفاءة المواد والإنتاج: يقيس العائد كم تحصل عليه من المدخلات الخام. رغوة EPS القابلة لإعادة تدويرها تزيدها إلى 98٪، مما يقلل من الخسائر. أظهرت بيانات K show 2025 أن هذا يوفر 10-15٪ على المواد سنويًا. بالنسبة للقوالب المخصصة ، مثل علب الكمبيوتر المحمول ، يعني العائد الأعلى المزيد من الإنتاج لكل دفعة. هذا’ مكاسب مباشرة.

- حماية متفوقة لتقليل الضررمعدلات الانكسار في الشحن يمكن أن تصل إلى 5٪. هواشنغ’ حلول التعبئة والتغليف s eps تنخفض إلى أقل من 1٪ مع تصاميم امتصاص الصدمات. في K 2025، أثبتت الاختبارات أن رغوتنا تتحمل قطرات من 1.5 متر. هذا يحمي الأشياء الثمينة مثل الشاشات ، وقطع العائدات. التعبئة المستدامة التي تدوم تبني الثقة.

- القيمة على المدى الطويل على التكلفة الأولية: مقدما ، تكلف الرغوة الممتازة أكثر - على سبيل المثال ، 10٪ إضافية. لكن طول العمر يعود. هواشنغ’ الرغوة EPS القابلة لإعادة التدوير تستمر من خلال 5-7 دورات ، مقابل 2-3 للأساسيات.

استنتاج

أظهرت المناقشات في K 2025 بوضوح أن صناعة التعبئة والتغليف تقف عند مفترق طرق. الطلب على المواد التي يمكن أن تلبي في نفس الوقت الكفاءة التشغيلية، وأهداف الاستدامة الصارمة، ومراقبة التكاليف لم يعد طموحا في المستقبل ولكن متطلبا حاليا. الابتكارات EPS هواشنغ تم تصميم العرض على المسرح العالمي بدقة لمواجهة هذا التحدي متعدد الأوجه وجها لوجه. نحن ملتزمون بتوفير ذكي ومستدام حلول EPS عالية الأداءالقضاء على الحاجة للاختيار بين ربحية الأعمال والكوكب.

إذا كان لديك صدى مع هذه الأفكار، يرجى زيارة موقعنا الإلكتروني لمعرفة عن منتجاتنا. لحلول التعبئة والتغليف EPS المخصصة، يرجى الاتصال HUASHENG المواد الجديدة في info@r-eps.com نحن مكرسون لخدمتك.