الحفاظ على المياه خارج هو أمر مهم جدا في تصميم المباني الحديثة. يساعد المباني على البقاء قوية وتوفير الطاقة. من بين مواد البناء ، فإن رغوة EPS (البوليستيرين الموسع) هي خيار رائع للعزل والحفاظ على الرطوبة بعيداً. هذا المقال يبحث عن كيفية عزل الرغوة الصلبة EPS يساعد على الرطوبة في بناء المظروف. نركز على ميزاتها وكيفية عملها وأين يتم استخدامها.

دور إدارة الرطوبة في مظروف البناء

التحكم الجيد في الرطوبة هو المفتاح للحفاظ على المباني قوية وصحية وذكية في استخدام الطاقة مع مرور الوقت.

أهمية التحكم في الرطوبة في البناء

تسلل المياه إلى المباني يمكن أن تفسد العزل. يمكن أن يقلل من جودة الهواء الداخلي. قد يؤدي حتى إلى إصلاحات مكلفة. إذا دخل الماء إلى الجدران أو الأسطح ، فإنه يمكن أن يضر بأجزاء من المبنى. كما يمكن أن يسبب نمو العفن. لذلك ، فإن استخدام المواد التي تمنع المياه هو أمر لا بد منه لأداء طويل الأمد.

عواقب سيئة التحكم في الرطوبة على أداء المبنى

المباني بدون حواجز مياه جيدة يمكن أن تواجه مشاكل. قد تفقد الحرارة عبر الجدران. المواد يمكن أن تتكسر. العفن أو الجراثيم يمكن أن تنمو. هذه المشاكل تجعل المباني أقل راحة. كما أنها تزيد تكاليف التدفئة والتبريد. هذا يجعل توفير الطاقة صعبا جدا.

رغوة EPS كمادة عزل صلبة

رغوة EPS شعبية في المنازل والشركات والمصانع. انها خفيفة ومذهلة في العزل.

الخصائص الرئيسية لرغوة EPS ذات الصلة بمقاومة الرطوبة

تتكون رغوة EPS من 98٪ من الهواء المحاصر في هيكل خلية مغلقة. هذا الإعداد يمنع الماء من التحرك من خلاله. بالإضافة إلى ذلك ، فإن EPS رائع في الحفاظ على الحرارة داخل أو خارج. وهذا يساعد المباني على استخدام طاقة أقل والبقاء جافة في الداخل.

مقارنة بين EPS ومواد العزل الأخرى

مقارنة بالألياف الزجاجية أو الصوف المعدني، يمتص EPS أقل من الماء مع مرور الوقت. تحتاج بعض المواد إلى طبقات إضافية لمنع المياه. لكن الـ EPS يقاوم الرطوبة بشكل طبيعي بسبب تصميمه المغلق. كما يحافظ على قوة العزل بشكل أفضل في ظروف رطبة من العديد من المواد الأخرى.

الآليات التي مقاومة الرغوة EPS الرطوبة

لفهم كيفية إبقاء المياه خارج الـ EPS ، نحتاج إلى النظر في هيكلها وميزاتها التي تمنع المياه من الدخول.

هيكل الخلايا المغلقة وتأثيرها على امتصاص المياه

EPS مصنوع من الخرز الصغيرة عالقة مع البخار. كل حبة لها جيوب هوائية مغلقة. هذه الجيوب تمنع الماء من المرور بسهولة. هذا يجعل EPS رائعًا في وقف تدفق الماء والغمر.

خصائص العمل الشعري وخصائص نفاذ البخار

لا يحب الـ EPS الماء بسبب مكياجه المغلق. لا يجذب الماء مثل المواد الإسفنجية. كما أنه يتيح القليل من بخار الماء من خلال. هذا يساعد على وقف التراكم الرطوبة في الجدران. لكنها لا تزال تسمح للجدران بالتجفيف. ويبين وحدة الطوارئ EPS الهيدروفوبية (معدل امتصاص المياه < 0.5 في المائة) كيف تعمل النسخ الخاصة بشكل جيد في المناطق الرطبة أو المعرضة للفيضانات.

استقرار الأبعاد على المدى الطويل في ظروف رطبة

يحافظ الـ EPS على شكله وحجمه حتى في ظروف رطبة أو رطبة. ولها سطح ناعم وتبقى قوية. حجمها لا يتغير كثيرا. وهذا يجعله مثاليًا لمناطق البناء الصعبة حيث البقاء مستقرًا مهمًا.

أداء رغوة EPS في مناطق مناخية مختلفة

يعمل العزل EPS بشكل جيد في جميع أنواع الطقس - من الأماكن الساخنة والرطبة إلى الأماكن الباردة المتجمدة. إنه خيار مرن للمشاريع في جميع أنحاء العالم.

السلوك في بيئات عالية الرطوبة

في المناطق الممطرة أو الساحلية ذات الكثير من الرطوبة ، يبقي EPS الماء خارجًا لفترة طويلة. إنه لا ينهار. هواشنغمادة EPS كبيرة في الكثافة والقوة والعزل الحراري. إنه يعمل بشكل جيد بغض النظر عن مدى رطوبة الهواء.

الأداء في دورات التجميد والذوبان والمناخ البارد

في الأماكن الباردة مع دورات التجميد والذوبان، يجب على المواد تجنب التكسير من الجليد. EPS لديه معدل امتصاص الماء منخفض (< 0.5٪). لا يحتوي على ما يكفي من الماء للتجمد والكسر. هذا يبقي المباني قوية وفعالة في استخدام الطاقة لسنوات عديدة.

دمج رغوة EPS في أنظمة مظروف البناء

للعمل بشكل أفضل ، يجب وضع EPS في الجدران أو الأسطح أو الأساس أو أجزاء أخرى بشكل صحيح. يجب أن تعمل مع المواد والأساليب الأخرى.

طرق التطبيق للجدران والسقوف والأسس

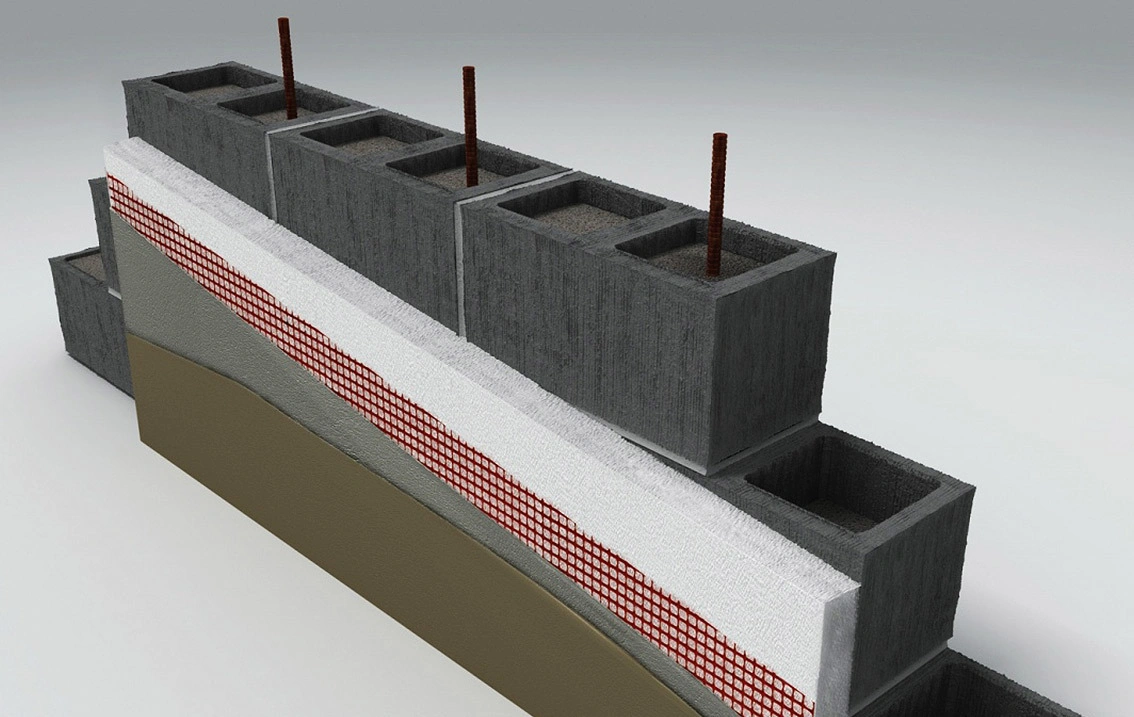

غالبا ما تستخدم لوحات EPS في الخارج في EIFS (أنظمة التشطيب العزل الخارجي). يذهبون تحت أغشية السقف كاللوحات المسطحة أو تلك المنحدرة للصرف الصحي. كما تستخدم حول الأساس حيث العزل المائي تحت الأرض هو المفتاح. مجال التطبيق: نظام عزل الجدران الخارجية للمبنى يظهر كيف تحسن هذه الطرق أداء المبنى بأكمله.

التوافق مع مواد البناء والأغشية الأخرى

يحصل EPS جنبا إلى جنب مع معظم الغراء ومواد الختم والأغشية (مثل البيتومين أو تلك القائمة على البوليمر). إنه يعمل مع الخرسانة، لوحات الجبس، وأكثر من ذلك. لا تتفاعل بشكل سيء معهم. هذا يجعل من السهل الاستخدام في إعدادات المباني المتدرجة دون التسبب في مشاكل.

تحسين المتانة وكفاءة الطاقة مع EPS

تقدم EPS مزيدتين كبيرتين: عزل كبير ومقاومة للماء. هذا يجعلها قيمة للغاية لخطط البناء الأخضر.

المساهمة في المقاومة الحرارية أثناء إدارة الرطوبة

EPS لديه موصلات حرارية منخفضة (منخفضة حتى 0.032 واط / م · ك). يظهر مربع EPS ذات التوصيل الحراري المنخفض جداً (λ = 0.032 W / m · K) هذا. كما أنه يستغرق القليل من الماء. هذا يساعد البناء على توفير الطاقة والحفاظ على الجدران أو العليا خالية من الرطوبة التي تسبب العفن.

يوفر HUASHENG مواد EPS عالية الجودة للعديد من الصناعات. تدعم رغوة EPS المعاد تدويرها الأهداف الخضراء ، مما يظهر كيف تتوافق الأهداف الصديقة للبيئة مع الاحتياجات التقنية.

تقليل خطر العفن والتعفن والتدهور الهيكلي

أجزاء البناء الجافة توقف العفن أو العفن من النمو. هذه تزدهر في الأماكن الرطبة. منتجات EPS لها مقاومة تأثير كبيرة وقوة. إنهم لا يحبون الماء ، لذلك يحموا الخشب من التعفن. وهذا يجعل المباني تستمر لفترة أطول.

HUASHENG: مورد موثوق به لمنتجات EPS عالية الجودة

HUASHENG لديها الكثير من الخبرة في صنع حلول EPS صديقة للبيئة. تقدم رغوة EPS المعاد تدويرها و حبات رغوة EPS للاستخدامات الخفيفة وتوفير الطاقة. وتستخدم هذه في البناء والتغليف والخدمات اللوجستية وسلاسل التبريد الطبية والمشاريع الفنية وأنظمة مكافحة الفيضانات وأكثر من ذلك.

نظرة عامة على درجات منتجات HUASHENG

منتجات هواشنغ تلبي احتياجات المشروع المحددة مع مزيجات خاصة:

الصف المشترك للتطبيقات العامة

الصف القياسي E-101 له حجم 1.30-1.60mm. إنه جيد للتغليف العام مثل الإلكترونيات أو السيراميك أو العوامات أو الحرف.

درجة مضادة للحريق للمشاريع الحساسة للحريق

حصلت جزيئات EPS المضادة للشعلة B1 (الكثافة 22 كيلوغرام / متر مكعب) على شهادة LEED Green Building Gold. انها رائعة للمشاريع الآمنة من الحرائق.

درجة الجرافيت لتحسين الأداء الحراري

EPS المضغوط بالجرافيت يزيد العزل عن طريق ارتداد الحرارة المشعة بعيدا. إنها مثالية للمباني التي لا تستخدم طاقة صفرية والتي تهدف إلى معايير المنزل السلبي.

درجة حماية البيئة لاحتياجات البناء الأخضر

REPS قابلة لإعادة التدوير وتتناسب مع فئة إعادة تدوير PS الدولية 6. إنه يعمل بشكل جيد ويأتي بألوان زاهية.

الكربون الأسود الصف لمقاومة الأشعة فوق البنفسجية والتطبيقات الجمالية

الكربون الأسود EPS يوفر حماية الأشعة فوق البنفسجية ويبدو جميلا. إنه رائع للاستخدامات المكشوفة مثل الألواح الزخرفية أو المشاريع الفنية.

حلول REPS مخصصة مصممة خصيصا لمتطلبات المشروع

HUASHENG تقدم EPS مخصصة عند الطلب مع استجابات سريعة. إنهم يصنعون حلول لمكافحة الفيضانات أو صناديق النقل للأدوية الحيوية. يتم إعادة تدوير 300,000 طن من EPS سنويا. منتجاتها تلبي معايير FDA و HACCP و LEED في جميع أنحاء العالم.

استنتاج

رغوة البوليستيرين الموسعة (EPS) هي مادة من الدرجة الأولى للحفاظ على الرطوبة خارج مظروف المبنى. هيكله المغلق يمنع الماء من التسلل ، في حين يوفر عزله الكبير الطاقة. يبقى EPS قويًا ومستقرًا ، حتى في ظروف رطبة أو متجمدة ، مما يجعل المباني تدوم لفترة أطول. الصفوف الخاصة لـ HUASHENG ، مثل مضاد اللهب والجرافيت وحماية البيئة والكربون الأسود ، تلبي احتياجات مختلفة مع دعم الأهداف الخضراء. وتضمن حلولها المعاد تدوير EPS (REPS) وحلولها المخصصة، مثل الجسيمات المضادة للشعلة E-101 أو B1، أعلى أداء. كمورد موثوق به ، تساعد HUASHENG على إنشاء مباني دائمة وذكية للطاقة وصديقة للبيئة. EPS هو لاعب رئيسي في بناء مستقبل مستدام.

الأسئلة الشائعة

Q1: هل البوليستيرين الموسع مقاوم للماء؟

ج: EPS ليست مقاومة للماء بالكامل مثل الأوراق البلاستيكية. لكنها مقاومة للماء للغاية. وهيكله المغلق يمنع معظم المياه من الدخول. وحدة الطوارئ EPS الهيدروفوبية (معدل امتصاص المياه < 0.5 في المائة) يثبت ذلك في استخدامات مثل أنظمة مكافحة الفيضانات.

Q2: هل يمكنني استخدام عزل رغوة EPS تحت الصف؟

ج: نعم! EPS لديه معدل امتصاص المياه منخفض وحجم مستقر. مادة EPS HUASHENG كبيرة في الكثافة للأسس. غالبا ما يستخدم حول القبو أو تحت الألواح حيث تلمسها التربة.

س3: كيف يمكن مقارنة EPS المعاد تدويره مع المواد العذراء؟

ج: REPS HUASHENG قوية وصعبة مثل المواد الجديدة. يستخدم المواد الخام المعاد تدويرها بنسبة 100٪. يقلل من استهلاك الطاقة بنحو 30%. وهذا يجعلها الخيار الأول للمشاريع الخضراء التي تهدف إلى تحقيق أهداف الاقتصاد الدائري.