صناعات التعبئة والتغليف وحاويات الأغذية تستخدم البوليستيرين الموسع (EPS) كمادة مرنة. لا تزال المادة شائعة لأنها توفر كل من الخفيفة الوزن وخصائص العزل وتسعير معقول. استخدام الـ EPS لتغليف الأغذية يخلق مخاوف بشأن سلامة المنتج والآثار البيئية.

ما هي فول البوليستيرين الموسعة؟

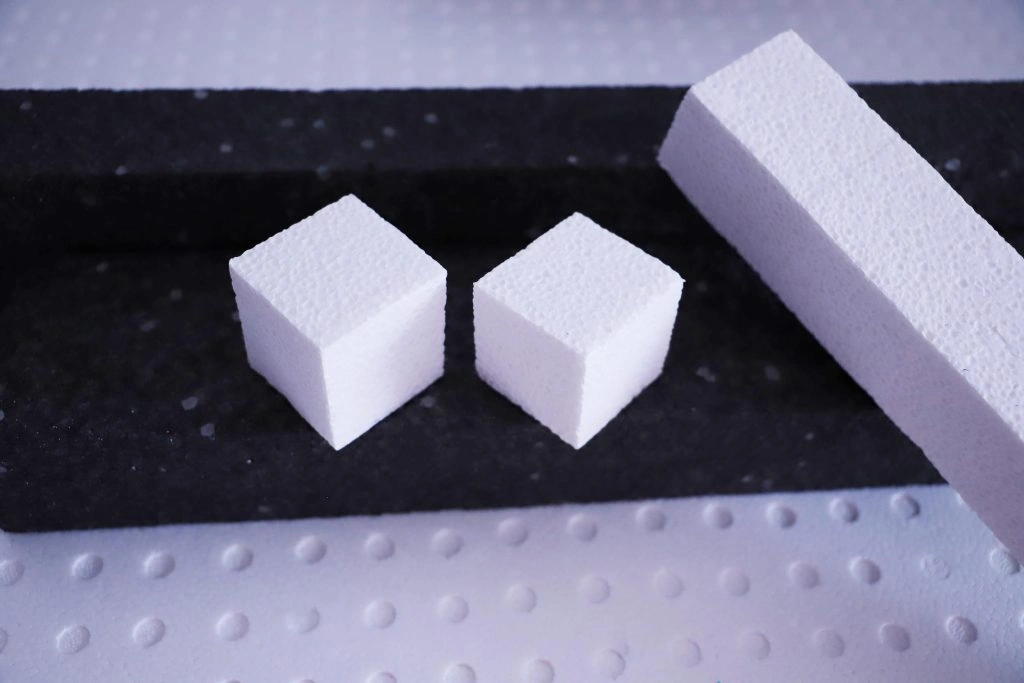

الفاصوليا الموسعة البوليستيرين (EPS) ، وغالبا ما تسمى حبات البوليستيرين ، هي جزيئات رغوة خفيفة الوزن ومتعددة الاستخدامات المستخدمة في تطبيقات مختلفة. لفهم خصائصها الفريدة، دعونا نستكشف تكوينها وخصائصها الفيزيائية. هذه الخرز مصنوعة من البوليستيرين ، بوليمر حراري بلاستيك ، تم توسيعه بواسطة عامل نفخ مثل البنتان.

التكوين والخصائص الفيزيائية

المكون الرئيسي لفاصوليا البولي ستيرين الموسعة يتكون من بوليمر البولي ستيرين الذي يشكل هياكل الخرز الصغيرة. تتضمن عملية تصنيع هذه الفاصوليا توسع البخار لإنشاء هياكل رغوة خفيفة الوزن ولكنها قوية. حجم الخرز الموحد وسيولة جزيئات الرغوة الممتازة تمكن من إزالة القوالب بسرعة على آلات التشكيل التلقائي بينما يعمل تبريد الفراغ بكفاءة ويظهر المنتج اندماج قوي ومقاومة تأثير عالية.

التطبيقات الشائعة في التعبئة والتغليف وحاويات الأغذية

تخدم الفاصوليا EPS كمادة أساسية لإنتاج حلول التعبئة والتغليف للأجهزة الكهربائية والسلع السيراميكية وحاويات الصيد وتعبئة الفواكه والخضروات والعوائم والحرف اليدوية. استخدام الفاصوليا EPS في حاويات الأغذية يبرز لأنها توفر الاحتفاظ بدرجة حرارة ممتازة وحماية النقل لمحتوياتها.

استخدام البوليستيرين الموسع في تغليف الأغذية

يستخدم البوليستيرين الموسع (EPS) على نطاق واسع في تغليف الأغذية بسبب خصائصه الفريدة. هنا هو السبب في أن EPS هو خيار شعبي لحاويات تناول الطعام. طبيعته الخفيفة الوزن والعزلة والفعالة من حيث التكلفة تجعلها مثالية للحفاظ على الأغذية الطازجة والأمنة.

لماذا يستخدم البوليستيرين الموسع في حاويات تناول الطعام

EPS هو الخيار المفضل لحاويات تناول الطعام لأنه يوفر عزل متفوق يحافظ على الطعام في درجة الحرارة المناسبة. المادة تعمل بشكل جيد لجميع أنواع الأغذية سواء كانت بحاجة إلى البقاء ساخنة أو باردة.

العزل الحراري والخصائص الخفيفة الوزن

توفر EPS العزل الحراري مع الحفاظ على هيكل خفيف الوزن يقلل من مصاريف الشحن ويعزز سهولة التعامل مع المستخدم ومزود الخدمة.

فعالية التكلفة لمقدمي خدمات الأغذية

توفر EPS لمزودي خدمات الأغذية حلاً اقتصادياً للتعبئة والتغليف مقارنةً بالمواد الأخرى المتاحة. تتطلب عملية تصنيع EPS الحد الأدنى من استهلاك الطاقة لإنتاج مادة توفر قدرات متانة وحماية ممتازة.

مخاوف الصحة والسلامة

المخاوف الصحية والسلامة مهمة عند استخدام البوليستيرين الموسع (EPS) في عبوات الأغذية. دعونا ندرس إمكانية الهجرة الكيميائية إلى الأغذية. تنشأ هذه المشكلة بسبب تكوين المادة والعوامل البيئية.

الهجرة الكيميائية المحتملة إلى الأغذية

وقد أثارت عملية انتقال المواد الكيميائية من EPS إلى المنتجات الغذائية مخاوف بين العلماء. تبين الأبحاث أن الستيرين يمكن أن ينتقل من مواد التعبئة والتغليف EPS عندما يتم تخزين أنواع معينة من الأغذية في هذه الحاويات في ظروف تخزين معينة.

تأثير درجة الحرارة ونوع الأغذية على السلامة

تعتمد سلامة حاويات EPS على درجة حرارة المواد الغذائية المخزنة بداخلها لأن الأغذية الساخنة يمكن أن تؤدي إلى التسرب الكيميائي. يصبح خطر التسرب الكيميائي أعلى عندما يتم تسخين الطعام إلى درجات حرارة عالية.

توجيهات تنظيمية من سلطات سلامة الأغذية

وتضع سلطات سلامة الأغذية مبادئ توجيهية تحدد ما إذا كانت مواد التعبئة والتغليف المستخدمة في المنتجات الغذائية آمنة للاستهلاك البشري. يجب على المصنعين الذين يستخدمون EPS في منتجاتهم اتباع هذه المعايير لسلامة المنتج.

التأثير البيئي للبوليستيرين الموسع

التأثير البيئي للبوليستيرين الموسع (EPS) هو مصدر قلق متزايد بسبب استمراره. دعونا نستكشف تحديات التحلل وإدارة النفايات. وتنتج هذه المسائل من طبيعتها غير القابلة للتحلل الحيوي وصعوبات التخلص منها.

قضايا التحلل وإدارة النفايات

ويخلق معدل التحلل البطيء لـ EPS صعوبات كبيرة لإدارة النفايات لأنه يبقى في مدافن النفايات لفترات طويلة قبل أن يظهر أي علامات على الانهيار. تبقى المادة في مدافن النفايات لفترات طويلة لأنها لا تتحلل بسرعة.

التحديات في إعادة تدوير البوليستيرين الموسع

تواجه إعادة تدوير الـ EPS عقبات متعددة لأن هناك مشاكل تلوث وتثبت عملية تحويلها إلى مواد قابلة للاستخدام أنها صعبة. وتواجه عملية إعادة التدوير تطورا مستمرا للتغلب على العقبات التشغيلية الحالية.

البدائل التي يتم النظر فيها في الصناعة

تسعى الصناعة إلى استبدال EPS من خلال المواد القابلة للتحلل الحيوي والبلاستيك القابل لإعادة التدوير التي توفر مزايا مماثلة مع تجنب المشاكل البيئية المرتبطة EPS.

البحوث العلمية حول سلامة الأغذية والتعرض لـ EPS

البحث العلمي حول سلامة الأغذية والتعرض لـ EPS أمر حيوي لفهم المخاطر. دعونا نستعرض على الدراسات حول هجرة الستيرين وصحة الإنسان. وتقيم هذه الدراسات التسرب الكيميائي المحتمل وآثاره.

دراسات حول هجرة الستيرين وصحة الإنسان

وقد ركزت الدراسات على عملية هجرة الستيرين من EPS إلى المواد الغذائية. تشير الأبحاث إلى أن الاستخدام القياسي لمنتجات EPS يمثل مخاطر صحية منخفضة ولكن العلماء يواصلون التحقيق في ملف تعريف السلامة الكامل.

حدود التعرض التي تحددها وكالات الصحة الدولية

وقد حددت الوكالات الصحية الدولية حدود التعرض للستيرين لحماية صحة المستهلك عندما تستخدم منتجات EPS لتغليف الأغذية.

الآثار على المدى الطويل والثغرات الحالية في المعرفة

يحتاج المجتمع العلمي إلى مراقبة آثار الهجرة الكيميائية لـ EPS مع مرور الوقت لأنه لا يزال هناك الكثير من المجهولات حول آثارها على المدى الطويل.

المشهد التنظيمي والمنظورات العالمية

يختلف المشهد التنظيمي للبوليستيرين الموسع (EPS) عالمياً، مما يعكس الأولويات المتنوعة. دعونا نقارن السياسات في الولايات المتحدة والاتحاد الأوروبي. هذه اللوائح تتناول السلامة والمخاوف البيئية وقيود الاستخدام.

السياسات في الولايات المتحدة والاتحاد الأوروبي

وقد وضع المجالان قواعد تتحكم في استخدام عبوات الأغذية EPS لأغراض السلامة وتعزيز إعادة التدوير.

الحظر والقيود في بلدان مختلفة

وقد فرضت عدة دول حظرا أو قيودا على منتجات EPS ذات الاستخدام الواحد بسبب المخاوف البيئية التي أدت إلى اعتماد حلول التعبئة والتغليف الصديقة للبيئة.

معايير الامتثال لمواد تغليف الأغذية

يجب على المصنعين اتباع المعايير التنظيمية لإنشاء مواد التعبئة والتغليف التي تحمي الصحة وتقليل الآثار البيئية.

HUASHENG: مورد موثوق به لمواد EPS

تعمل شركة هواشنغ تشيهانغ (تيانجين) للتجارة الدولية المحدودة كشركة تنتج مواد EPS عالية الأداء لاستخدامات مختلفة بما في ذلك حلول الرغوة المعاد تدويرها. تعمل الشركة كمصنع رائد لمنتجات EPS.

نظرة عامة على درجات منتجات EPS HUASHENG

هواشنغ يوفر منتجات EPS بمستويات جودة مختلفة لتلبية متطلبات العملاء المختلفة.

الصف المشترك

الصف الشائع: P-مادة خفيفة إضافية مناسبة لاحتياجات التعبئة والتغليف العامة بما في ذلك الأجهزة الكهربائية والسيراميك. P-مادة خفيفة إضافية

درجة مضادة للشعلة

تقدم درجات مقاومة اللهب خصائص سلامة محسنة تجعلها مناسبة لتطبيقات مواد البناء. F-درجة مضادة للشعلة

الجرافيت الصف

وقد تم تعزيز خصائص العزل الحراري لصفوف الجرافيت من خلال تطوير FGE-الجرافيت بوليستيرين.

درجة حماية البيئة

تتبع درجات حماية البيئة معايير الاتحاد الأوروبي لتوفير خيارات مستدامة للسوق. إن FHE-N-HBCD درجة مضادة للشعلة.

الكربون الأسود الصف

تتطلب التطبيقات المتخصصة درجات الكربون الأسود التي توفر خصائص مضادة للستاتيك وموصلية حرارية منخفضة لمواد FGE في البوليستيرين.

حلول REPS المخصصة

يوفر HUASHENG حلول شخصية تتطابق مع متطلبات العملاء الفردية لدقة دقيقة. خدمة مخصصة

الالتزام بالجودة والسلامة والاستدامة

تقوم شركة هواشنغ بنهجها التصنيعي على الابتكار مع إعطاء الأولوية للممارسات المستدامة التي تلبي معايير الصناعة العالمية للخضراء تصنيع EPS ذكي.

استنتاج

يتم تقدير البوليستيرين الموسع (EPS) في التعبئة والتغليف وحاويات الأغذية لخصائصه الخفيفة الوزن والعزل والفعالة من حيث التكلفة. ومع ذلك، لا تزال هناك مخاوف بشأن هجرة الستيرين إلى الأغذية عند درجات الحرارة العالية والتحديات البيئية بسبب بطء التحلل وصعوبات إعادة التدوير. والامتثال التنظيمي والبدائل المستدامة أمران حاسمان لمعالجة هذه القضايا. شركات مثل هواشنغ تقود بحلول EPS مبتكرة وصديقة للبيئة، وتلبي المعايير العالمية. تهدف جهود البحث والصناعة المستمرة إلى التوازن بين الوظائف والسلامة والاستدامة.

الأسئلة الشائعة:

Q1: هل من الآمن استخدام حاويات البوليستيرين الموسعة للأغذية الساخنة؟

ج: خصائص العزل من البولي ستيرين الموسع تجعلها مناسبة لنقل الأغذية ولكن المستخدمين بحاجة إلى الحذر لأن درجات الحرارة العالية يمكن أن تؤدي إلى التسرب الكيميائي في الأغذية أثناء التعرض الطويل.

Q2: هل يمكن إعادة تدوير البوليستيرين الموسع؟

ج: تتطلب عملية إعادة التدوير عمليات فرز وتنظيف مفصلة قبل إعادة المعالجة إلى أشكال قابلة للاستخدام، ولكن العمل الجاري يواصل تعزيز الكفاءة وتقليل النفايات إلى أدنى حد من خلال الممارسات المسؤولة التي تعزز أنظمة الاقتصاد الدائري في الصناعات التي تستخدم هذه المادة بشكل كبير في جميع أنحاء العالم.

Q3: ما الذي يجعل منتجات EPS HUASHENG مختلفة؟

ج: تبرز هواشنغ لأنها تركز على الجودة والابتكار من خلال التصنيع الذكي الذي ينتج حلول صديقة للبيئة عالية الأداء لمختلف الصناعات مع اتباع جميع قواعد الإنتاج والتوزيع الدولية لقاعدة عملائها في جميع أنحاء العالم.