في العالم المتوسع لعلوم المواد والإنتاج، البوليستيرين الموسع (EPS) تبرز في تصنيع الرغوة المخصصة. إنها خفيفة ومذهلة في الحفاظ على الأشياء الساخنة أو الباردة ومرنة للغاية. هذا يجعل EPS المفضلة في العديد من المجالات. يحمي المواد الهشة مثل الإلكترونيات أثناء النقل. كما يساعد المباني على استخدام طاقة أقل. مزيجها من الأداء الصلب والصفات الخضراء يجعله خيارًا رائعًا.

نظرة عامة على مواد EPS في تصنيع الرغوة

البوليستيرين الموسع هو رغوة قاسية ومغلقة الخلايا تم إنشاؤها من حبات البوليستيرين. هذه الخرز تتنفخ بالبخار. النتيجة هي مادة خفيفة ولكن قوية. إنها مثالية للعديد من الوظائف المختلفة.

الخصائص الرئيسية للبوليستيرين الموسع (EPS)

EPS يحافظ على الحرارة داخل أو خارج بشكل جيد حقا. يحتفظ بشكله ، ولا يمتص الماء ، ويتعامل مع الضغط. إنها رخيصة وسهلة العفن ، ومثالية لحماية العائمة أو الصدمة. هذه الصفات تجعلها مثالية للتعبئة والبناء.

مقارنة مع مواد الرغوة الأخرى

مقارنة بالرغوة البولي يوريثان أو البولي إيثيلين ، غالبا ما يكون EPS أكثر صلابة. إنها تعزل الحرارة بشكل أفضل وتكلف أقل. البولي يوريثان ينحني بسهولة أكبر، والبولي إيثيلين يأتي في سماك مختلفة. ومع ذلك ، فإن EPS هو الأفضل للوظائف التي تحتاج إلى دعم قوي ومقاومة للحرارة.

لماذا يستخدم EPS على نطاق واسع في صناعات التصنيع

HUASHENG ، مورد EPS الرائد ، يقدم EPS من الدرجة الأولى للعديد من الصناعات. تقدم EPS المعاد تدويرها للمشاريع الصديقة للبيئة ، وألواح EPS للمباني الموفرة للطاقة ، والرغوة الواقية للشحن. ويأتي استخدامه الواسع من تركيب طرق الإنتاج المختلفة وتلبية احتياجات محددة.

مزايا EPS في تصنيع الرغوة المخصصة

يحتوي EPS على صفات خاصة تجعله رائعًا للمشاريع المخصصة. يجلب فوائد كبيرة في الميزات التقنية.

خصائص خفيفة الوزن والقوة الهيكلية

EPS ، مثل المواد الخفيفة الوزن من نوع P من HUASHENG ، توسع طنًا (تصل إلى 80-100 مرة). هذا يخلق منتجات خفيفة للغاية. ومع ذلك، يبقى الـ EPS قويًا بما فيه الكفاية للتغليف الوقائي وأجزاء البناء.

قدرات العزل الحراري

الصف S-32 المعزز بالجرافيت لديه موصلية حرارية حوالي 0.031 واط / م · ك. هذا أفضل بنسبة تصل إلى 25٪ من EPS العادي (حوالي 0.041 واط / م · ك). إنه رائع للمباني الفعالة في استخدام الطاقة والحفاظ على الأمور باردة أثناء الشحن.

مقاومة الرطوبة والمتانة

الهيكل المغلق لـ EPS يمنع المياه من الدخول. وهذا يجعلها تدوم في الأماكن الرطبة، مثل الجدران الخارجية أو أنظمة النقل المبردة.

فعالية التكلفة وكفاءة المواد

إنتاج EPS HUASHENG يتبع قواعد خضراء صارمة. يستخدم طاقة أقل بنسبة 30٪ من الطرق القديمة. التوسع الكبير والتكاليف المنخفضة والقدرة على إعادة التدوير تجعل EPS اختيار صديق للمحفظة.

التطبيقات الشائعة لـ EPS عبر الصناعات

تساعد الخصائص المتنوعة لـ EPS العديد من الصناعات التي تحتاج إلى حماية أو عزل أو مواد خفيفة.

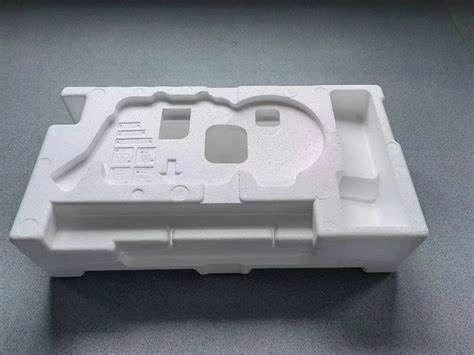

حلول التعبئة والتغليف للسلع الهشة والإلكترونيات

تم تصميم EPS سريع النماذج الأولية من الدرجة B لتعبئة الإلكترونيات والأشياء الحساسة مثل السيراميك. يعمل بشكل رائع مع آلات الصب الآلية. إنه يعطي إنتاج سريع وحماية صدمة قوية.

مكونات عزل البناء والبناء

تلبي EPS المضادة للشعلة من الدرجة F شهادة UL في الولايات المتحدة ومعايير GB8624-2012 في الصين. هذا يبقي المباني آمنة. تقدم الدرجات المعززة بالجرافيت مثل S-33 كفاءة حرارية ممتازة للهياكل الموفرة للطاقة.

مكونات السيارات والفضاء

أجزاء EPS تجعل السيارات أخف وزناً لكنها لا تزال قوية. تضمن درجات مضادة للحريق أنها تتبع قواعد السلامة من الحريق.

الاستخدامات الإبداعية في العرض والإشارات والنماذج الأولية

يعتبر EPS المعاد تدويره (REPS) ناجحة في صنع الشاشات ، مثل دعم التلفزيون للعلامات التجارية مثل OC. تجاوز اختبارات المصنع الصعبة. تساعد قابلية صبها على إنشاء تصاميم باردة للعلامات والنماذج الأولية السريعة.

إمكانات التخصيص لمواد EPS

EPS رائع لتصنيع الرغوة المخصصة. مرنة في التشكيل والأداء.

المرونة في القطع والتشكيل والصب

يمكن قطع EPS بالضبط مع آلات CNC أو صبها إلى أشكال صعبة. هذا يسبب القليل من النفايات ويتناسب مع العديد من احتياجات المشروع.

تقنيات القطع CNC للتصنيع الدقيق

يقدم القطع الذي يتحكم به الكمبيوتر دقة كبيرة لأشياء مثل نماذج البناء أو إدراجات التعبئة والتغليف المخصصة. يبقي المادة قوية.

صب مقابل قطع تطبيقات EPS

يمنح EPS المصبوب جودة ثابتة لعمليات الإنتاج الكبيرة. يعمل Cut EPS بشكل أفضل للدفعات الصغيرة أو التصاميم التي تتغير كثيراً.

معالجات السطح والطلاء لتحسين الأداء

الطلاءات تعزز مقاومة الأشعة فوق البنفسجية والمظهر. على سبيل المثال ، يحارب EPS الكربون الأسود من فئة FGE من HUASHENG الشيخوخة ويلبي معايير السلامة من الحرائق B1 (GB8624-2012). انها رائعة للاستخدام في الهواء الطلق.

درجات EPS المتخصصة للاحتياجات المحددة

هواشنغ يوفر درجات EPS خاصة مصممة لاحتياجات الصناعة.

الصف المشترك للتطبيقات القياسية

EPS القياسي E-grade جيد للاستخدامات اليومية مثل التعبئة والتغليف الإلكترونية والعزل الأساسي. لديها سمك متوازن وأداء.

درجة مضادة للشعلة للامتثال للسلامة

يتفوق EPS المضاد للشعلة من فئة FSH على معايير B1 العادية. هو أكثر من 20٪ أقوى في الضغط. يفي بمعايير UL و GB8624-2012 ، مما يجعله مثاليًا للبناء.

درجة الجرافيت لتحسين أداء العزل

يستخدم الصف المعزز بالجرافيت S-33 الجرافيت الطبيعي لتمتص الإشعاع تحت الحمراء. هذا يعزز العزل الحراري لتصاميم المنازل السلبية وأنظمة سلسلة البرد.

درجة حماية البيئة للمشاريع المستدامة

يستخدم FHE-grade مضادات اللهب غير HBCD. يتوافق مع معايير الاتحاد الأوروبي REACH و RoHS. يدعم البناء الصديق للبيئة مع الحفاظ على السلامة والقوة من الحرائق.

الكربون الأسود الصف لمقاومة الأشعة فوق البنفسجية والاستخدام في الهواء الطلق

يحتوي الكربون الأسود EPS من فئة FGE على موصلة حرارية منخفضة وميزات مضادة للستاتيك. يتوافق مع السلامة من الحرائق B1 (GB8624-2012). إنها مثالية للوظائف في الهواء الطلق التي تحتاج إلى مقاومة الأشعة فوق البنفسجية.

هواشنغ: مورد موثوق لحلول EPS المخصصة

HUASHENG تقود مع حلول EPS الخضراء الإبداعية.

نظرة عامة على مجموعة منتجات وقدرات HUASHENG

شركة هواشينغ تشيهانغ (تيانجين) للتجارة الدولية تعمل على البحث وتطوير وصنع ومشاركة مواد EPS. تشمل مجموعة من الدرجات القياسية مثل P-grade EPS خفيفة الوزن ، S-32 المعززة بالجرافيت إس - 33، ومتقدمة FGE الكربون الأسود EPS.

الخبرة في درجات EPS المتخصصة

الخبرة التقنية لـ HUASHENG تضمن جودة ثابتة. وتلبي منتجاتها معايير الصناعة للسمك والقوة والعزل عبر العديد من الاستخدامات.

حلول مصممة خصيصاً للاحتياجات المحددة للصناعة

HUASHENG تقدم مزيجات EPS مخصصة. إنهم يعدلون الخصائص مثل السمك أو الامتثال الأخضر لتتناسب مع احتياجات المشروع المحددة.

العوامل التي يجب مراعاتها عند اختيار EPS للتصنيع المخصص

اختيار درجة EPS المناسبة يعني التوازن بين الاحتياجات التقنية والقانونية.

متطلبات المشروع: الكثافة والقوة واحتياجات العزل

بالنسبة لأجهزة العوام ، فإن EPS خفيفة الوزن من الدرجة P (نسبة التوسع 80-100) مثالية. تحتاج الألواح الهيكلية إلى EPS الأكثر كثافة من فئة FSH لمقاومة اللهب للحصول على صلابة إضافية.

الامتثال لمعايير الصناعة ولوائح السلامة

تحتاج مشاريع البناء في كثير من الأحيان إلى مقاومة اللهب المصنفة B1 (GB8624-2012) أو شهادة UL. تأكد من أن الدرجة المختارة تلبي القواعد المحلية والعالمية.

الاعتبارات البيئية وخيارات إعادة التدوير

يستخدم EPS المعاد تدويره من HUASHENG (REPS) المواد الخام المعاد تدويرها بنسبة 100٪. يستخدم أكثر من 95٪ من نفايات الإنتاج. هذا يدعم الأهداف البيئية ويخفض الانبعاثات.

استنتاج

البوليستيرين الموسع (EPS) هو مادة متعددة الاستخدامات عالية الأداء لتصنيع الرغوة المخصصة. هو خفيف، يعزل بشكل جيد، ويستمر لفترة طويلة. الحلول المخصصة لـ HUASHENG ، مثل مقاومة اللهب والجرافيت وحماية البيئة ، تلبي العديد من احتياجات الصناعة. كما أنها تدفع الممارسات الخضراء مع إنتاج وتوفير الطاقة وإعادة تدويرها. كمورد موثوق به، HUASHENG تساعد الشركات على تحقيق الأداء والأهداف البيئية. EPS هو جزء كبير من المستقبل الأخضر.

الأسئلة الشائعة

Q1: ما الذي يجعل EPS المعزز بالجرافيت أفضل من EPS الأبيض القياسي؟

ج: يحتوي EPS المعزز بالجرافيت ، مثل الصف S-33 لـ HUASHENG ، على جزيئات جرافيت. هذه تعزز العزل الحراري بنسبة تصل إلى 25٪ (0.031 واط / م · ك مقابل 0.041 واط / م · ك ل EPS القياسية). إنها رائعة للمباني الموفرة للطاقة والتبريد.

Q2: يمكن استخدام درجات EPS التي تؤدي إلى إبطاء اللهب في الهواء الطلق؟

ج: نعم ، يقاوم EPS الكربون الأسود من فئة HUASHENG الأشعة فوق البنفسجية. تلبي معايير السلامة من الحرائق B1 (GB8624-2012). هذا يجعلها دائمة وآمنة للاستخدام في الهواء الطلق.

Q3: كيف صديقة للبيئة هو HUASHENG إعادة تدوير EPS (REPS) ؟

ج: يستخدم HUASHENG REPS المواد الخام المعاد تدويرها بنسبة 100٪. يستخدم أكثر من 95٪ من نفايات الإنتاج. هذا يدعم الاقتصاد الدائري مع الحفاظ على الأداء للشاشات والمنازل الموحدة.