يعرف البوليستيرين الموسع (EPS) بشكل أفضل للحفاظ على الأمور دافئة أو باردة ، ولكن مزاياه تتجاوز ذلك بكثير. إنه قوي ، لا يتلف بالماء ، ويمكن إعادة تدويره ، ويقدم أطنان من الخيارات للتصميم. هذه الصفات تجعل EPS ضروري في العديد من المجالات. مع تركيز العالم أكثر على كونها صديقة للبيئة ، من المهم جدا لكل من الشركات والناس العاديين أن يعرفوا ما يمكن لمنتجات البولي ستيرين الموسعة فعلا.

خفيفة الوزن ولكنها قوية هيكلياً

واحد من أروع الأشياء حول EPS هو كيف يخلط بين أن تكون خفيفة جدا مع أن تكون صعبة حقا. هذا يجعلها مثالية للأشياء التي تحتاج إلى أن تكون سهلة الحمل ولكن أيضا قوية بما فيه الكفاية لتستمر.

كيف يجمع البوليستيرين الموسع بين الوزن المنخفض والقوة العالية

يتكون EPS من 98٪ من الهواء و 2٪ فقط من البوليستيرين. ومع ذلك ، فهي قوية بشكل مفاجئ بسبب تصميمها الخاص بالخلايا المغلقة. هذا الإعداد يسمح له بأخذ ضربات دون فقدان شكله أو انهيار. لانزو هواشنغ جلبت المواد الجديدة أساليب رغوة EPS الراقية وأدوات اختبار عالية الجودة. إنهم يتأكدون من أن منتجاتهم تبرز في أشياء مثل الكثافة وحتى، والقوة تحت الضغط، والحفاظ على الحرارة أو البرد في. هذه الميزات تجعل EPS الاختيار الأفضل في المناطق التي يكون القوة مهمة بنفس القدر من البقاء خفيفة.

التطبيقات التي تستفيد من سلامتها الهيكلية

قوة EPS تأتي في متناول اليد في الكثير من الاستخدامات في العالم الحقيقي.

حلول التعبئة والتغليف والشحن

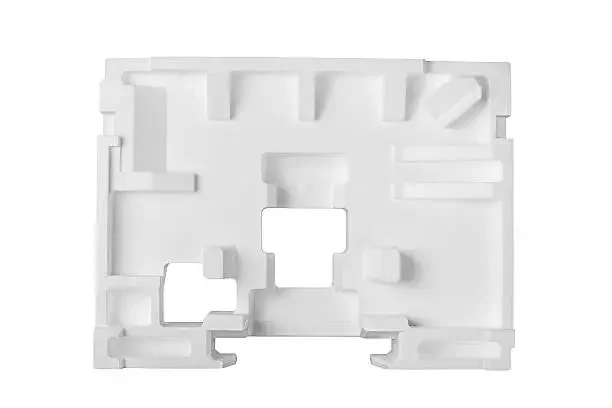

في عالم التعبئة والشحن ، تقدم HUASHENG خيارات رغوة EPS خفيفة ولكن صعبة. هذه الحفاظ على البنود آمنة أثناء نقلها. فهي تحمي من الاصطدامات والاهتزازات والضربات الصلبة. هذا هو السبب في أن الـ EPS رائع لحماية الأشياء الحساسة مثل الأدوات والأدوات الطبية وقطع غيار الآلات أثناء النقل.

استخدامات البناء التي تحمل الحمل

كما تلعب EPS دورا كبيرا في مشاريع البناء. يستخدم كطبقة لنشر الوزن تحت الطرق ومسارات القطار وقواعد البناء. عندما يتعلق الأمر بالهياكل العازلة ، فإن منتجات رغوة EPS من HUASHENG مدهشة. يمكنهم التعامل مع الوزن دون جعل الأشياء ثقيلة. هذا يقلل من الإجهاد على الأشياء تحت مع الحفاظ على كل شيء ثابت.

مقاومة الرطوبة والمتانة

بالإضافة إلى كونها قوية لوزنها ، فإن البوليستيرين الموسع رائع في مكافحة المياه. هذا هو زائد كبير للبقاء صعبا في جميع أنواع الأماكن مع مرور الوقت.

الأداء في البيئات الرطبة أو الرطبة

لا يمتص EPS الماء بسهولة بفضل بناء الخلايا المغلقة. وهذا يحافظ عليها آمنة من الانهيار عندما تصبح رطبة. يبقى نفس الحجم والشكل حتى في الأماكن الرطبة. هذا مفتاح للاستخدامات مثل عزل السقف أو المشاريع بالقرب من المحيط.

استقرار المواد على المدى الطويل مع مرور الوقت

العديد من المواد تتلاشى على مر السنين من أشياء مثل الرطوبة أو العفن. لكن EPS تحمل أفضل بكثير.

مقاومة العفن والعفن

بما أن EPS لا يمسك بالماء ، فإنه يحارب بشكل طبيعي العفن والعفن. هذا يساعد على الحفاظ على الهواء النظيف في الداخل عندما يستخدم في الجدران أو أنظمة التدفئة والتبريد.

استخدام في التخزين البارد والإعدادات البحرية

إن قدرة الـ EPS على مقاومة الماء تجعلها مثالية لأماكن التخزين البارد حيث غالباً ما تتراكم الرطوبة. هذه المنتجات رائعة في منع الحرارة أو البرد، مما يقلل من استهلاك الطاقة في المباني. في الاستخدامات القائمة على المياه مثل الموانئ العائمة أو دعم القوارب ، يستمر EPS في العمل بشكل جيد حتى عندما يكون دائما حول الماء.

الكفاءة البيئية والقدرة على إعادة التدوير

ومع تزايد صرامة القواعد المتعلقة بحماية الكوكب في كل مكان، أصبحت المواد التي تعمل بشكل جيد ولطيفة مع الأرض أكثر شعبية. EPS تناسب هذه الحاجة بشكل صحيح.

كفاءة الطاقة طوال دورة حياة المنتج

EPS يعمل كدروع صلب ضد الحرارة أو البرد. هذا يساعد على الحفاظ على مساحات داخلية مريحة على مدار السنة. ونتيجة لذلك ، هناك حاجة أقل إلى أجهزة التدفئة أو مكيفات الهواء. هذا يوفر الطاقة لسنوات عديدة. وعلاوة على ذلك، جعل EPS أصبح أكثر خضرة. تساعد الأفكار الجديدة مثل نماذج الكمبيوتر على استخدام موارد أقل أثناء صنعها.

عمليات إعادة تدوير منتجات البوليستيرين الموسعة

طرق إعادة تدوير EPS تحسنت كثيرا في السنوات القليلة الماضية.

أنظمة إعادة تدوير الحلقة المغلقة

في مصانع EPS اليوم، يتم إعادة استخدام أكثر من 95٪ من نفايات المصانع. هذا يظهر مدى إمكانية تحويل هذه المواد إلى أشياء جديدة. يبقى EPS الآمن للأغذية الذي يلبي قواعد FDA 21 CFR 177.1640 آمنًا حتى بعد إعادة استخدامه مرات عديدة.

المساهمة في شهادات البناء المستدام

يمكن لـ EPS المساعدة في كسب النقاط لجوائز البناء الصديقة للبيئة مثل LEED. في مشروع واحد يسمى GreenBuild Eco-city ، عزز استخدام B1 EPS من درجة إبطال اللهب توفير الطاقة للمبنى بنسبة 14٪. حتى حصل هذا المشروع على جائزة LEED الذهبية.

التنوع عبر الصناعات

من مواقع البناء إلى ورش العمل الفنية ، يتناسب البوليستيرين الموسع في كل مكان. إمكانية تشكيلها واستخدامها بطرق عديدة تجعل ذلك ممكناً.

قابلية تكييف EPS في مختلف القطاعات

تتيح مرونته للناس إنشاء تصاميم مباني فريدة من نوعها. هذا يساعد الفنانين والبنائين على تحويل أفكارهم البرية إلى أشياء حقيقية.

تغليف الأغذية والتطبيقات الطبية

بما أن الـ EPS آمن ويتوافق مع قواعد الأغذية ، فإنه غالبا ما يستخدم في صناديق الأغذية والمبردات الطبية. يجب أن تبقى نظيفة وتحافظ على درجة الحرارة المناسبة.

الاستخدامات الإبداعية في التصميم والفن وإنتاج الأحداث

سواء كانت تفاصيل المبنى الرائعة أو تصاميم الجدران الجميلة أو التماثيل الباردة ، فإن رغوة EPS سهلة القطع أو الشكل أو الطلاء. يقدم أفكارا لا نهاية لها للإنشاء. بالإضافة إلى ذلك ، فهي خفيفة بما فيه الكفاية لإعدادات قصيرة الأجل أو أدوات المسرح في الأحداث.

هواشنغ: مورد موثوق لحلول EPS

لانتشو هواشنغ المواد الجديدة المحدودة هي رائدة في صنع منتجات البوليستيرين الموسعة عالية الجودة. تم تصميمها لتلبية احتياجات اليوم.

نظرة عامة على درجات المنتج وقدرات HUASHENG

تشمل العناصر الرئيسية لـ HUASHENG أنواع مختلفة من EPS مثل الصف المشترك ، الصف المضاد للشعلة ، وصف الجرافيت. هذه تلبي جميع أنواع الاحتياجات، من التعبئة للزلازل إلى المباني الجاهزة.

الصف المشترك للتطبيقات العامة

هذا النوع يعمل بشكل جيد للاستخدامات العادية. فكر في أشياء مثل صناديق الأغذية القابلة للتخلص أو التعبئة الوقائية الأساسية حيث يكون حجب الحرارة العادي كافيا.

درجة مضادة للشعلة لمعايير السلامة المحسنة

ساعدت جزيئات EPS من الدرجة B1 التي تؤدي إلى إبطاء اللهب ، بكثافة 22 كيلوغرام / متر مكعب ، المشاريع الكبيرة على توفير الطاقة وتلبية قواعد السلامة من الحرائق في نفس الوقت.

الصف الجرافيت للأداء الحراري المتفوق

هذا النوع يحتوي على قطع الجرافيت مختلطة في ترتد الحرارة مرة أخرى. إنه يعطي حظر حرارة أفضل لكل بوصة من ورق رغوة EPS البيضاء العادية.

درجة حماية البيئة للمشاريع الواعية بالبيئة

يستخدم كثيرا في خطوط التعبئة القابلة لإعادة الاستخدام مثل EcoPack ، هذا الصف يحتوي على بت EPS قابلة لإعادة التدوير بنسبة 100٪. تم إعادة استخدامها خمس مرات. وهذا خفض تكاليف التعبئة والتغليف بنسبة 28٪ ورفع درجات البيئة بنسبة 22 نقطة.

الكربون الأسود الصف لمقاومة الأشعة فوق البنفسجية والاحتياجات الجمالية

هذا النوع يبدو جيدا ويحارب الضرر الشمسي. إنها مثالية للاشارات في الهواء الطلق أو تصاميم الجدران الجميلة التي تبقى في الشمس لفترة طويلة.

مخصصة REPS مصممة لمتطلبات الصناعة المحددة

كما يجعل HUASHENG خيارات خاصة من البوليستيرين الموسع المعاد تدويره (REPS). يتم التحقق منها بموجب قواعد ISO 14067:2018. ولديهم بصمة كربونية منخفضة تبلغ 719.14 كيلوغرام من ثاني أكسيد الكربون فقط. ₂ لكل طن. هذا يساعد على دعم الخطط الصديقة للبيئة من البداية إلى النهاية في العديد من المجالات.

الأسئلة الشائعة:

Q1: ما الذي يجعل البوليستيرين الموسع مختلف عن أنواع أخرى من مواد الرغوة؟

ج: البوليستيرين الموسع خاص بسبب إعداده الخلية المغلقة. هذا يعطيها حجب حراري كبير بينما تبقى خفيفة. على عكس بعض الرغوة التي تتكسر أو تمتص الماء مع مرور الوقت، يحافظ EPS على شكله حتى تحت الوزن أو في الأماكن الرطبة. بالإضافة إلى ذلك ، يمكن إعادة تدويره ، مما يميزه عن العديد من الرغوة التي يمكنك استخدامها مرة واحدة فقط.

Q2: هل يمكن إعادة تدوير البوليستيرين الموسع بفعالية؟

ج: نعم، بالتأكيد يمكن. تتيح طرق إعادة التدوير الجديدة لنفايات EPS ، حتى من المستخدمين العاديين ، أن تتحول إلى عناصر جديدة. يحدث هذا من خلال الطحن البسيط أو طرق التكنولوجيا العالية مثل الحرق دون الأكسجين. تستخدم بعض عمليات إعادة التدوير سوائل آمنة مثل د-ليمونين لجعل EPS جيدًا مثل الجديد. هذا يساعد على بناء نظام يستمر فيه إعادة استخدام المواد.

Q3: هل البوليستيرين الموسع آمن للاستخدام في التعبئة والتغليف للأغذية؟

ج: بالتأكيد. يتوافق EPS المعاد تدويره الآمن للأغذية مع القواعد الصارمة مثل FDA 21 CFR 177.1640. وهذا يعني أنه من الآمن لمس الطعام حتى بعد إعادة استخدامه مرات عديدة. لا يوجد أي قلق بشأن المخاطر الصحية معها.