يسمى الكثير من الناس كل رغوة بيضاء "Styrofoam"، ولكن هذا ليس صحيحا تمامًا. Styrofoam هو في الواقع اسم العلامة التجارية لنوع خاص من رغوة البولي ستيرين المقطوعة (XPS). المعركة الحقيقية هي بين البوليستيرين الموسع (EPS) و XPS. يأتي EPS من الخرز الصغيرة التي تنمو وتلتزم مع بعضها البعض. إنها خفيفة جداً ورخيصة ، مثالية للأكواب والأشياء التعبئة. يتم ضغط XPS مثل معجون الأسنان في لوحات صلبة. هذا يجعلها أصعب، ويحافظ على المياه بشكل أفضل، ويوقف الحرارة من الهروب بشكل أسرع. اختر واحد خاطئ في موقع العمل والأمور يمكن أن تسير بشكل سيء حقا.

فهم رغوة البوليستيرين وأهميتها الصناعية

توضيح المصطلح ساستيروفوم" و في السياقات التقنية

Styrofoam هو اسم مملوك لشركة واحدة. يعني فقط لوحات الرغوة المزروعة الزرقاء أو الوردية. معظم الناس يستخدمون هذه الكلمة لأي رغوة أبيضة يرونها. إنهم يشيرون إلى أكواب القهوة أو حشو الصناديق ويقولون "استيروفوم". هذا خطأ. هذه هي عادة EPS ، وليس Styrofoam الحقيقي.

الرغوة الحقيقية هي دائما رغوة البولي ستيرين المقطوعة (XPS). إنها ليست مادة الخرز. يمكن لخلطهم أن يسبب مشاكل كبيرة في بناء الوظائف.

الكيمياء وراء رغوة البوليستيرين

كلا النوعين تبدأ بنفس البلاستيك الأساسي - البوليستيرين. تحول المصانع الستيرين السائل إلى حبات صغيرة صلبة أو حبات. هذا هو الجزء السهل.

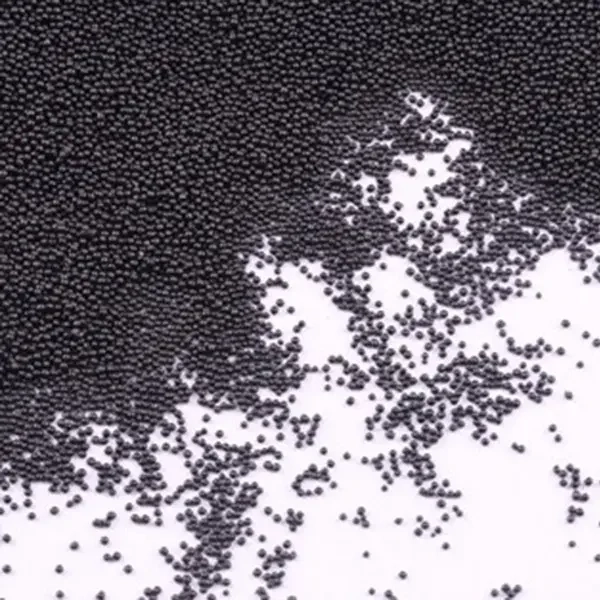

بالنسبة لـ EPS ، وضعوا غاز خاص داخل الخرز. البخار يجعل الخرز تنفخ ضخمة، ثم تلصق نفسها معا في كتل أو أشكال.

بالنسبة لـ XPS ، فإنهم يذوبون الكريات بالكامل. ثم يدفعون الغو الساخن من خلال فتحة. يبرد إلى أوراق ناعمة وقوية. نفس العائلة، أطفال مختلفون تماماً

الاختلافات الرئيسية بين EPS و XPS Foam

الخصائص الهيكلية والميكانيكية

EPS تبدو ككرات صغيرة مضغوطة مع بعضها البعض. يمكنك أحيانًا رؤية الأشكال المستديرة إذا كسرتها. هناك فجوات صغيرة بين الكرات. هذا يبقيها خفيفة ولكن ليس قوية للغاية.

XPS ليس لديه كرات على الإطلاق. كل شيء قطعة واحدة سلسة. لا ثغرات. هذا يجعل من الصعب كسر وأقوى بكثير عندما يجلس شيء ثقيل عليه.

مقارنة خصائص الأداء

أداء العزل الحراري

XPS يفوز في الحفاظ على الحرارة في الداخل. الخلايا صغيرة ومغلقة تماماً. الحرارة لديها صعوبة في التسلل من خلال. يعمل EPS بشكل جيد في الوظائف العادية ، لكنه يتيح المزيد من الحرارة الانزلاق بعيدا.

مقاومة الرطوبة والمتانة

الماء يكره XPS. حتى لو دفنته في التراب الرطب، فإنه يبقى جافا في الداخل. يمكن لـ EPS شرب القليل من الماء من خلال تلك الفجوات الصغيرة بين الخرز. بمجرد أن تصبح رطبة ، فإنه لا يحتفظ بالحرارة أيضًا.

قوة الضغط والقدرة على تحمل الحمل

ضع شاحنة على XPS وتضحك. ضع نفس الشاحنة على EPS العادي وتضغط مسطحة. هذا هو السبب في أن XPS يذهب تحت الأرضيات الخرسانية وEPS لا.

مقارنة التطبيقات: حيث EPS مقابل XPS منطقي

الاستخدامات النموذجية للبوليستيرين الموسع (EPS)

EPS هو ملك الوظائف الرخيصة والخفيفة:

– زوايا الرغوة التي تحمي تلفزيونك الجديد في الصندوق

– أكواب القهوة البيضاء وصناديق الخروج

– الكتل الكبيرة التي تملأ المساحة تحت الطرق أو التلال

تلمس EPS تقريبا كل يوم.

التطبيقات الشائعة لوحات رغوة البوليستيرين المقطوعة (XPS)

يظهر XPS أين تصبح الأمور صعبة:

– لوحات وردية أو زرقاء على جدران القبو

– تحت الخرسانة في أرضية المرآب

– عزل سقف مسطح لا يرى الماء يدخل أبدا

يستفيد المصنعون من XPS عندما لا يستطيعون تحمل تكاليف الأخطاء.

حلول البوليستيرين الجرافيت المطروعة المتقدمة بواسطة HUASHENG

مقدمة لمنتجات بوليستيرين الجرافيت من سلسلة S من HUASHENG

HUASHENG يأخذ رغوة البوليستيرين العادية ويضيف قطع الجرافيت لامعة صغيرة. تلك القطع ترتد الحرارة مرة أخرى مثل المرآة. تحصل على دفء أفضل من نفس السمك.

S-32 الجرافيت البوليستيرين (طريقة البثق) نظرة عامة

إن إس - 32 لوحات مختلطة الجرافيت مباشرة في. موجات الحرارة ضربت أجزاء لامعة وترتد مرة أخرى داخل المنزل. مثالية للجدران والسقوف عندما تريد التغلب على قواعد الطاقة الصعبة دون إنفاق المال المجنون.

S33 الجرافيت البوليستيرين (طريقة البثق) نظرة عامة

S33 هو الأخ الأصعب. إنه مصنوع للشتاء البارد والأرض الرطبة. تجميد وتذوب كل ما تريد - يبقى مستقيما وقويا. رائع لمشاريع البناء الخضراء التي تحتاج إلى أعلى درجات.

الاعتبارات البيئية لرغوة البوليستيرين

التحديات في إعادة تدوير مواد EPS و XPS

يمكن إعادة تدوير كلا النوعين ، ولكن ليس من السهل. تصبح EPS قذرة مع الطعام أو الشريط. معظم المدن لن تأخذها. XPS نظيفة ولكنها سميكة جداً، لذلك يجب على الآلات الخاصة سحقها أولاً. ليس في كثير من الأماكن هذه الآلات.

التأثير البيئي للتخلص غير السليم

هذه الرغوة لا تتعفن أبدا. اتركهم في الطبيعة وتبقى للأبد. الرياح تهب قطع صغيرة مكسورة في الأنهار والمحيطات. الحيوانات تأكلها. ليس جيداً

البدائل والابتكارات المستدامة

هواشنغ يساعد على جعل المباني تستخدم طاقة أقل للحرارة والتبريد. كما يعيدون استخدام مخلفات المصانع لصنع لوحات جديدة. النتيجة هي تقليل النفايات أقل بنفس الكثير المنتج.

معالجة المفاهيم الخاطئة الشائعة حول مصطلحات "Styrofoam"

لماذا غالبا ما يتم إساءة استخدام مصطلح "Styrofoam"

شركة كبيرة واحدة جعلت الرغوة الزرقاء مشهورة قبل سنوات. بدأ الجميع يدعو كل الرغوة البيضاء بهذا الاسم، حتى عندما كانت أشياء مختلفة تماما. الآن الاسم الخاطئ عالق.

أهمية تحديد المواد بشكل صحيح في الاستخدام المهني

في الوظائف الحقيقية ، تكلف الأخطاء المال الكبير. ضع الـ EPS الرخيص تحت لوحة بدلاً من الـ XPS ويمكن أن تتصدع الأرضية. الماء يدخل المبنى يفشل في التفتيش اقرأ دائما التسمية ومعرفة ما تشتريه بالضبط.

الأسئلة الشائعة

س: ما هي حبات رغوة البوليستيرين مصنوعة من؟

ج: تبدأ الخرز كقطع صغيرة من البلاستيك الصلب. المصانع تصنعها عن طريق انضمام قطع الستيرين معا. ثم يضيفون غازا حتى يتمكن البخار من تفجيرهم بشكل كبير في وقت لاحق.

س: كيف يعزز الجرافيت أداء رغوة البوليستيرين؟

ج: تتصرف قطع الجرافيت الرمادي الصغيرة مثل المرايا داخل الرغوة. إنهم يرتدون أشعة الحرارة مرة أخرى إلى المكان الذي أتوا منه. تخرج حرارة أقل ، لذلك يبقى منزلك أكثر دفئاً مع لوحات أرق.

س: يمكن HUASHENG’ s سلسلة S الجرافيت البوليستيرين تستخدم تحت الصف؟

ج: نعم! كل من S32 و S33 قوي ويحافظ على الماء خارج. تعمل بشكل رائع تحت لوحات الخرسانة أو خارج جدران القبو حيث تبقى الأرض رطبة.