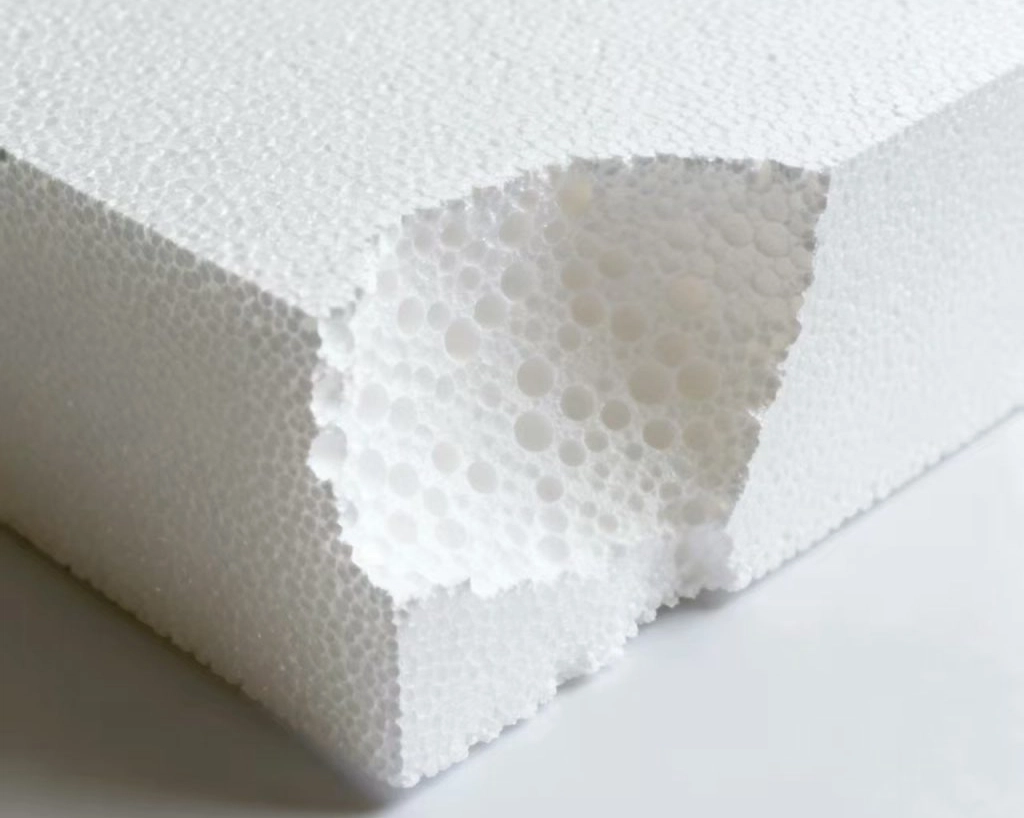

في عالم البناء اليوم ، يواجه البناء والمهندسون المعماريون سؤالًا صعبًا. كيف نتمكن من تحقيق الأهداف الخضراء دون التخلص من السلامة من الحرائق؟ رغوة البوليستيرين الموسعة ، والتي غالبا ما تسمى EPS ، تبرز كخيار عزل أعلى. ومع ذلك، فإن مقاومة اللهب لها أهمية كبيرة. يساعد مضاد اللهب EPS على الحفاظ على أمان المباني مع تقليل استهلاك الطاقة. ولكن ليس كل الخيارات توازن السلامة مع صديقة البيئة. هذا هو المكان الذي تدخل فيه شركة HUASHENG EPS ذات الصف FSH. هذا المنشور يغطس في سبب قصور البوليستيرين التقليدي المضاد للشعلة وكيف يلمع منتجنا FSH. سنغطي التحديات الرئيسية والمزايا والنصائح لاختيار المنتجات المضادة للحريق المناسبة. إذا كنت تخطط لمشروع، تبقى حول لمعرفة كيف يمكن للرغوة EPS المخصصة تناسب احتياجاتك.

لماذا يواجه الـ EPS التقليدي المضاد للشعلة تحديات اليوم

خدمت EPS التقليدية المضادة للشعلة الصناعة لسنوات. يوفر عزل جيد وبعض مقاومة الحريق. لكن الأوقات تتغير القواعد الجديدة والمطالب الخضراء تكشف نقاط ضعفها. دعونا نكسر هذا.

الجدل حول مضادات اللهب القائمة على الهالوجين

تعتمد العديد من الأنواع القديمة من البوليستيرين المضاد للشعلة على الهالوجينات مثل البروم أو الكلور. هذه المواد الكيميائية تبطئ الحرائق عن طريق إطلاق الغازات التي تخنق اللهب. يبدو مفيداً، أليس كذلك؟ ولكن هنا هو الصيد. عندما تحترق، يمكنها إطلاق الدخان السام. تظهر الدراسات أن هذه الدخانات تضر بالصحة والبيئة. على سبيل المثال ، في حالة حريق ، قد ينقذ مضاد الحريق EPS القائم على الهالوجين الهيكل ولكن يعرض الناس في الداخل للخطر.

هذه المسألة تضرب المنزل للمبنيين الذين يهدفون إلى مساحات آمنة. تتشكك مقاومة البوليستيرين للحريق عندما تدخل السموم الصورة. وقد قامت مجموعات مثل الاتحاد الأوروبي بالتخلص تدريجياً من بعض الهالوجينات بسبب مخاطر التلوث. إذا استخدم مشروعك هذه ، فقد تواجه ردود فعل من العملاء أو المنظمين. لا يتعلق الأمر فقط برموز الاجتماع اليوم - بل يتعلق الأمر بتثبيت المستقبل.

الاختلال بين الأداء والاستدامة

رغوة البوليستيرين الموسعة من حيث الأداء تتميز في الحفاظ على الحرارة داخل أو خارج. أضف مضادات اللهب، وتحصل على البوليستيرين المقاوم للحريق الذي يحمل في الاختبارات. ولكن الاستدامة غالبا ما تأخذ مقعد خلفي. المضافات الهالوجينية لا تتحلل بسهولة. إنها تبقى في التربة والماء ، مما يسبب أضرار طويلة الأجل.

فكر في موقع بناء نموذجي. تريد منتجات مضادة للحريق التي تعزل بشكل جيد دون إضافة إلى أكوام النفايات. الخيارات التقليدية تفرض تبادل. قد تعني مقاومة الحريق العالية درجات بيئية منخفضة. يظهر هذا الاختلال في تصنيفات المباني الخضراء ، حيث تهم النقاط للمواد. تخسر المشاريع إذا لم تكن EPS مستدامة حقاً.

وعلاوة على ذلك، يستخدم إنتاج هذه المواد موارد يمكن توفيرها. العمليات الكثيفة الطاقة تضيف إلى بصمة الكربون. ومع تشديد الأهداف المناخية، تتوسع هذه الفجوة. يحتاج البناء إلى خيارات توفر على كل من الجبهتين دون تنازل. وهذا يقودنا إلى عقبة أخرى: مواكبة القوانين المتطورة.

القيود على التكيف مع اللوائح المستقبلية

التنظيمات تتطور بسرعة. ما مرر بالأمس قد يفشل غداً تكافح EPS التقليدية المضادة للشعلة هنا. كثيرون لا يستوفون المعايير القادمة للانبعاثات أو قابلية إعادة التدوير. على سبيل المثال، تتطلب قواعد الاتحاد الأوروبي الجديدة أقل مركبات عضوية متطايرة في مواد البناء.

إذا كنت تشتري رغوة EPS مخصصة، تحقق من المرونة. الصيغ القديمة تقفلك في التكنولوجيا القديمة. الترقية تعني تكاليف إضافية أو تأخيرات. على النقيض من ذلك ، تتكيف المنتجات المتطلعة بشكل أفضل. لقد رأينا حالات توقفت فيها المشاريع بسبب مقاومة حريق البوليستيرين غير المتوافقة. تجنب هذا الصداع عن طريق النظر إلى الأمام. تتحول الصناعة نحو البدائل الخالية من الهالوجين ، مما يجعل الرهانات التقليدية أكثر خطورة.

الآن بعد أن قمنا بتغطية هذه التحديات، فمن الواضح لماذا يهم الابتكار. أدخل EPS من فئة FSH من HUASHENG - نظرة جديدة على خلط السلامة والممارسات الخضراء.

FSH درجة EPS رغوة: حل مزدوج للسلامة والاستدامة

تقدم FSH-grade من HUASHENG طريقة ذكية للأمام. هذا البوليستيرين المضاد للشعلة يجمع بين الحماية من الحريق من الدرجة الأولى وتصميم صديق للبيئة. صممت خصيصا للبناء الحديث، حيث كل خيار يهم. دعونا نستكشف ما يميزها.

الميزة الأساسية للتكنولوجيا الخالية من الهالوجين

في قلب FSH هو التكنولوجيا الخالية من الهالوجين. على عكس الطرق القديمة ، فإنه يستخدم إضافات أكثر أمانا لتحقيق مقاومة اللهب. وهذا يعني عدم وجود إطلاقات سامة أثناء الحرائق. تظهر الاختبارات أنها تلبي المعايير الأوروبية الصارمة مثل EN 13501-1 ، مما يكسب تصنيفات حريق عالية. لماذا هذا مهم لمشروعك؟ EPS مضاد للاشتعال بدون الهالوجينات يقلل من المخاطر الصحية. وسهل إعادة تدويرها، وقطع النفايات.

هواشنغ تصنع هذه الرغوة البوليستيرين الموسعة بدقة. عمليتنا تضمن الجودة المتسقة. سواء كنت بحاجة إلى رغوة EPS مخصصة للجدران أو الأسطح، توفر FSH مقاومة حريق البوليستيرين الموثوقة. ولكن الأمر ليس فقط عن السلامة. تتوافق هذه التكنولوجيا مع الاتجاهات الخضراء ، مما يمهد الطريق لشهادات أوسع.

اجتماعات أنظمة تصنيف المباني الخضراء

وتكافئ أنظمة البناء الخضراء مثل LEED أو BREEAM الخيارات المستدامة. البوليستيرين المضاد للشعلة من فئة FSH يحصل على درجات جيدة هنا. تأثيره البيئي المنخفض يعزز تقييم مشروعك. أولا، يمكن أن تقلل من استهلاك الطاقة للمبنى. ثانيا، العزل الجيد يعني احتياجات أقل من التدفئة أو التبريد. وهذا يعني انخفاض الفواتير وبصمة الكربون الأصغر.

لقد زودت HUASHENG FSH للمشاريع التي تحصل على أعلى علامات بيئية. مثال واحد: وصلت سيارة تجارية بنيت في أوروبا إلى وضع البلاتين جزئيا بفضل مضاد الحريق EPS لدينا. التفاصيل مثل هذه تظهر الفوز في العالم الحقيقي. وعلاوة على ذلك، وبناء على ذلك، فإن نسخة HUASHENG تجلب المزيد إلى الطاولة.

أداء متفوق من HUASHENG FSH رغوة

ما الذي يجعل FSH HUASHENG مميزة؟ ابدأ بتصنيعنا. نستخدم الخرز المتقدمة لرغوة البوليستيرين الموسعة الموحدة. هذا يؤدي إلى تحكم أفضل في الكثافة والقوة.

في اختبارات الحريق ، يحتفظ EPS المضاد للشعلة بشكله لفترة أطول. هذا يشتري الوقت للإخلاء. يتفاخر العملاء بمتانتها في ظروف قاسية. التخصيص هو المفتاح أيضًا. تحتاج أحجام أو كثافات محددة؟ خيارات رغوة EPS المخصصة تناسب أي تصميم. من السكن إلى الصناعي ، يتكيف FSH.

لدينا دراسات حالة لإثبات ذلك. استخدم مشروع مستودع البوليستيرين المضاد للحريق لتلبية قوانين الحريق الصارمة مع البقاء أخضرًا. النتائج؟ هيكل أكثر أمانا، أصحاب أكثر سعادة. مع هذه نقاط القوة في الاعتبار ، يصبح اختيار المادة المناسبة مباشرة. ولكن كيف تتنقل في الخيارات؟

كيفية اختيار رغوة EPS المناسبة لمشروعك

اختيار EPS ليس تخمينًا. إنه يتضمن خطوات ذكية. سواء كنت متعاقدا أو مصمما، ركز على الحقائق. إليك كيفية إجراء اختيارات مستنيرة لمثبط اللهب EPS.

فهم الشهادات وأوراق البيانات

معلومات الشهادة مهمة. ابحث عن تصنيفات الحريق مثل UL أو ASTM. لحماية البيئة، ابحث عن علامات صديقة للبيئة مثل مهد إلى مهد (C2C).

- أأكسيجين أناndexأرقام أعلى تعني مقاومة أفضل للشعلة.

- دالإنسيتي &Sقوةتؤثر هذه على مدى أداء رغوة EPS بشكل جيد مع مرور الوقت.

- تصنيف الحريقيضمن أنها تلبي الرموز المحلية.

- العلامة البيئيةيؤكد ادعاءات الاستدامة.

- المقاومة الحرارية: يقيس قوة العزل.

- بيانات سلامة الموادتفاصيل عن الهالوجينات أو المضافات.

اعتبر هذه النقاط الرئيسية قائمة فحص. سوف تساعدك على تحديد منتجات مضادة للشعلة عالية الجودة بسرعة. بمجرد حصولك على هذه المعلومات ، قم بعمق عن طريق سؤال المورد.

طرح الأسئلة الصحيحة

- هل هو خالي من الهالوجين؟

هذا يفكك الضجة المحيطة بالبوليستيرين المضاد للحريق. - أي حريق دولي &هل تتوافق مع القوانين البيئية؟

إجابة جيدة تظهر أنها مضاد للشعلة EPS موثوق به. - هل هناك أمثلة على المشاريع؟

الأمثلة في العالم الحقيقي تبني الثقة في البوليستيرين المضاد للشعلة. - هل يمكنهم تخصيص رغوة EPS لمواصفاتك؟

المرونة مهمة بالنسبة للمباني الفريدة.

هذه الأسئلة سوف تضمن لك الحصول على مواد من الدرجة الأولى. سوف تحول الفخاخ المحتملة إلى مزايا.

استنتاج

اختيار المواد يجب’ t يعني اختيار الجانبين. هواشنغمن FSH درجة EPS رغوة يظهر أن السلامة والأهداف الخضراء يمكن أن تتوافق تماما. يوفر هذا EPS المضاد للشعلة مقاومة حريق قوية من البوليستيرين دون عيوب بيئية.

إذا كنت بحاجة إلى رفع مشروعك، يرجى الاتصال بنا على info@r-eps.com. نحن دائما على استعداد لتقديم التفاصيل التقنية وتقارير الاختبار وقصص النجاح. وفي الوقت نفسه، نتطلع أيضًا إلى إقامة تعاون طويل الأجل معكم في المستقبل، ودعونا نعمل معاً لبناء مباني أكثر أمانًا وأخضرًا!