In today’s crazy-fast supply chains, choosing the right packaging can mean the difference between profit and loss. Expanded Polystyrene (EPS) foam is a real standout, packing lightweight toughness with costs that won’t empty your wallet. It’s awesome for protecting fragile electronics or keeping food fresh. This piece digs into what makes EPS a packaging superstar, from its cheap production to handy logistics and recycling potential, plus how folks like HUASHENG are shaking things up with custom solutions.

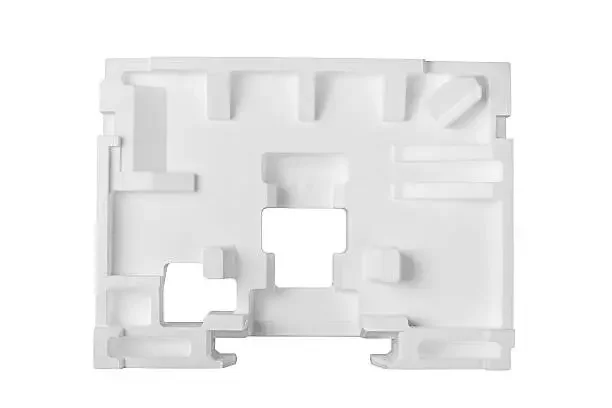

Expanded Polystyrene in Packaging Applications

Expanded Polystyrene (EPS) is a go-to material for modern packaging because it’s got a great mix of strength and money-saving perks. When you’re looking for something that works well and doesn’t break the bank, EPS is usually at the top of the list. It’s flexible and works for tons of industries, like electronics and food.

Key Properties Relevant to Packaging

EPS is mostly air—about 98%—which makes it really light. Even so, it stays tough and holds its shape under pressure. It’s awesome at soaking up bumps, which is perfect for protecting fragile stuff during shipping. Also, EPS is great at keeping things hot or cold, so it’s a top choice for things like medicines or fresh food that need to stay at the right temperature.

Its closed-cell design keeps water and germs out. That makes it super useful for all kinds of jobs. These features cut down on damaged goods and save money in shipping and storage.

Industry Adoption Across Sectors

Thanks to these cool qualities, EPS is used all over the place. Electronics companies love it for protecting delicate parts. The food world uses EPS boxes for hot or cold items because it keep temperatures steady. Even in construction, EPS wraps up heavy or weird-shaped items to keep them safe.

This wide use shows how adaptable EPS is. It’s a smart pick for businesses needing packaging that’s both affordable and reliable.

Cost Structure of Expanded Polystyrene

Sure, performance matters, but cost is a huge deal when choosing materials. EPS shines because it’s not just good—it’s also cheap compared to other options.

Raw Material and Manufacturing Costs

EPS comes from styrene monomer, made through a process that uses steam and pentane gas to puff it up. The raw stuff doesn’t cost much compared to fancy plastics or eco-friendly options. Plus, making EPS doesn’t use a ton of energy since the final product is so light.

The setup for molding EPS is pretty simple, too, unlike materials that need complicated machines. This keeps costs low, especially when you’re making a lot of it.

Comparison with Alternative Packaging Materials

When you stack EPS up against things like molded pulp, cardboard, or biodegradable plastics, EPS often comes out as the cheapest per piece. This is especially true when you think about shipping costs, since EPS is so light. While some other materials might be better for the environment, they usually cost more, which can be tough to justify unless there’s a rule or branding reason.

For businesses watching their budgets, EPS gives the most bang for their buck.

Operational Advantages for Businesses

EPS isn’t just cheap to buy—it saves money in other ways, too, making it a great deal overall.

Lightweight and Transport Efficiency

Since EPS is so light but still strong, it cuts down on shipping costs. This is a big win for air freight or long-distance hauls where weight really adds up.

Plus, its lightness makes it easier for workers to handle during loading and unloading. That means less tiredness and safer workplaces.

Storage and Handling Benefits

EPS stacks neatly and holds its shape, so you can make the most of warehouse space without worrying about it getting squished. Unlike some flimsier materials that bend or need special storage conditions, EPS stays solid in normal settings.

These perks save money on storage space and handling costs.

Lifecycle and Reusability Considerations

People often think EPS is just for one-time use because it’s so common in throwaway packaging. But it’s got more staying power than you might expect.

Durability and Single-Use Economics

In lots of cases—like insulated boxes or corner protectors—EPS can be used again and again without wearing out. Even if it’s just used once, it’s so cheap that it’s still worth it for big operations. For companies with tight budgets or huge shipping networks, this makes EPS a smart choice.

Recycling Potential and End-of-Life Management

EPS is 100% recyclable. You can grind it into pellets to make new things like picture frames or insulation boards. Collection systems vary by place, but companies with good recycling programs can keep EPS out of landfills.

This recyclability helps ease worries about the environment while keeping costs low and fitting with green goals.

Market Trends and Pricing Dynamics

EPS’s low cost isn’t set in stone—it depends on what’s happening in the global supply chain, and buyers need to keep an eye on it.

Global Supply Chain Factors

The price of raw styrene can go up or down with oil prices since it comes from petroleum. But because EPS is mostly air, price swings don’t hit it as hard as denser plastics like PET or PVC.

Since the pandemic, supply chains have gotten stronger, with production hubs in places like Asia-Pacific, North America, and Europe keeping EPS available.

Regional Price Variations and Forecasts

Prices can change a lot depending on local energy costs (used to expand EPS), worker wages, shipping setup, and rules about disposal. But areas with strong recycling systems are seeing steady or even dropping prices because they rely less on new materials.

Buyers planning long-term need to stay on top of local market trends to get the best deals on EPS.

HUASHENG’s Expanded Polystyrene Solutions

When you need EPS products made just for your packaging needs—and with reliable quality—HUASHENG is a top choice. They’ve got years of experience making custom EPS for all kinds of industries, from foam blocks for electronics to food containers that keep temperatures right.

HUASHENG offers a big production capacity and strict quality checks. Whether you need standard sizes or custom designs for your shipping needs, they deliver precise products at good prices without slowing you down or skimping on toughness. HUASHENG stands out because their EPS products work great but don’t cost a fortune. Their materials keep all the important protective features while being molded consistently, which cuts down on waste during packing. They’re also made to work with automated systems if you need that.

Their global reach means fast delivery, no matter where you are, which is huge when demand spikes out of nowhere.

Strategic Recommendations for Procurement Decision-Makers

If you’re in charge of picking packaging that balances tight budgets with high performance across different shipping channels, EPS should be at the top of your list. It’s proven to keep total costs low while giving great protection for every gram shipped.

To get the best results:

- Check suppliers for more than just price—look at how well they control density.

- Think about setting up recycling programs where you can.

- Keep an eye on local price trends tied to styrene costs.

- Go with vendors like HUASHENG who offer custom options and global shipping support.

By looking at everything—from raw material costs to what happens after use—you’ll get the most value from EPS, one of the best packaging materials out there.

FAQ

Q: Is expanded polystyrene cheaper than biodegradable alternatives?

A: Yup. Per piece—and especially when you factor in shipping weight—EPS usually costs less than eco-friendly options like PLA-based foam or molded pulp trays.

Q: Can expanded polystyrene be reused?

A: Totally. While it’s often used once for convenience, things like insulation boxes or corner protectors can handle multiple uses without falling apart.

Q: What industries benefit most from using expanded polystyrene?

A: Industries like electronics, medicine shipping, food delivery, and heavy equipment transport all get big wins from EPS’s light weight, strength, and low cost.