Polystyrene seldom finds application in situations completely free from mechanical stress. In thermal insulation systems, protective packaging designs, and cushioning elements, the effects of compression determine whether the substance fulfills its intended purpose or directly fails. When subjected to compressive forces, polystyrene undergoes alterations not merely on the exterior but throughout its microscopic cellular framework. Such internal modifications determine the material’s load tolerance, recovery behavior, and long-term reliability across real service environments.

Why does compression behavior matter in polystyrene applications?

Compression represents a routine condition rather than an unusual phenomenon for polystyrene products. Therefore, any assessment of appropriateness needs to examine long-term response patterns instead of relying solely on short-term laboratory tests.

What types of compression occur in real-world use?

Polystyrene undergoes steady compressive forces in scenes involving constant weight, such as building envelopes or stacked packages. Besides, sudden compressive events arise from impacts, vibrations, and shocks during transportation. In some cases, repeated loading cycles take place, gradually reshaping the internal structure even when individual force peaks stay relatively modest.

Why is compression not a purely mechanical issue?

Deformation under pressure influences far more than exterior shapes. Compressive action modifies enclosed gas quantities, disrupts pathways for heat movement, and redistributes internal forces in the molded parts. Should deformation surpass defined thresholds, the loss of performance becomes irreversible and spreads to other layers in the system.

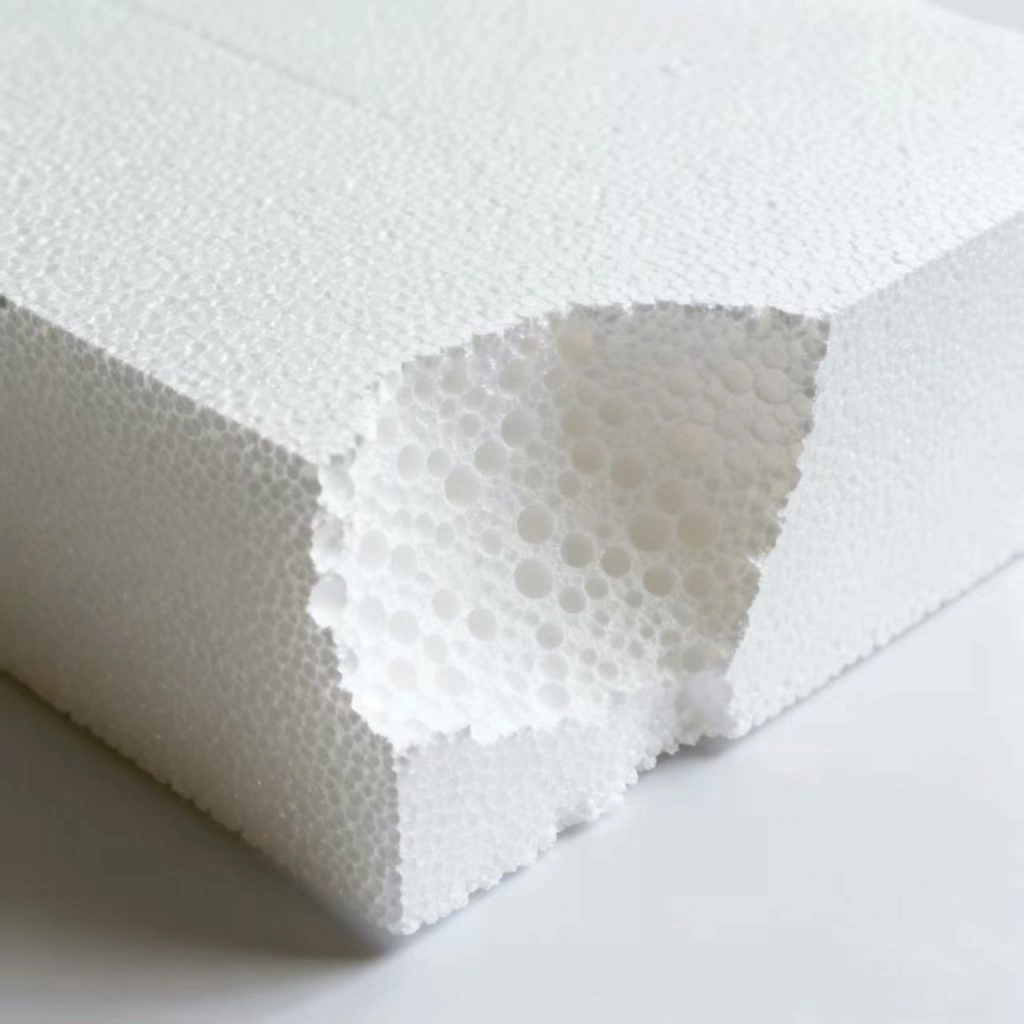

What happens inside polystyrene at the cellular level during compression?

Observable changes in polystyrene under load originate from microscopic events affecting individual beads and enclosed cells. Applied pressure initiates a series of structural adjustments that determine whether the changed shape can be restored.

How do closed-cell structures react to applied pressure?

With rising pressure, cell walls become noticeably thinner and localized buckling emerges. Once passing a critical yield point, cell walls fracture, the cell walls fracture, permitting trapped gas to release and producing permanent changes to the overall foam structure.

When does compression become irreversible?

Permanent change commences following cell wall fracture. From that moment, the material loses significant rebound capability, internal pressure balance collapses, and localized density rises sharply. Continued compression accelerates the structural breakdown and forms hardened regions prone to concentrating further stress.

How does compression affect thermal performance?

Effective heat insulation in polystyrene depends upon intact closed cells and closed gas volumes. Compression directly interferes with both essential features.

Why does reduced thickness change heat transfer?

As compressive forces decrease cell sizes, the proportion of solid polymer relative to insulating gas rises accordingly. Additional solid pathways facilitate greater heat conduction. Even a slight reduction in overall thickness can enhance the material’s effective thermal conductivity due to internal reorganization.

Is thermal loss proportional to compression?

Degradation in insulating capability follows a nonlinear pattern. Slight elastic deformation exerts minimal influence, but once structural collapse begins, thermal performance deteriorates rapidly. This is why load-appropriate density selection is critical in insulation applications.

How does material formulation influence compression resistance?

Ability to resist compression is not only determined by simple density, but also by polymer chain length, incorporated additives, and specific manufacturing techniques, which collectively determine stress absorption and distribution characteristics.

Why do graphite-modified materials behave differently?

The formulations of polystyrene containing graphite integrate infrared-influencing particles that modify the mechanical response. Elevated molecular weight base polymers combined with strengthened cell boundaries delay structural failure and enhance protection against lasting shape alteration.

Graphite polystyrene-S-32 material emerges through an extrusion process, incorporating infrared-absorbing graphite along with reinforcing components. Its combination of superior compressive resistance and shape retention suits applications demanding simultaneous thermal effectiveness and structural endurance.

What role does flame-retardant design play under compression?

Assessment of combustion characteristics and compression response typically proceeds separately, although both rely fundamentally upon preservation of the foam’s structural arrangement.

Does compression influence flame-retardant effectiveness?

Severe compression may disturb even dispersal of fire-inhibiting additives and modify routes available for oxygen penetration. Collapsed cellular regions often diminish the material’s capacity to resist ignition or achieve intended self-extinguishing behavior.

Why are European-standard formulations relevant?

Flame-retardant grades developed according to European standards prioritize consistent fire behavior even when exposed to mechanical loading. Products, such as FSH-european standard flame retardant grade material, preserve elevated compressive capability alongside compliance with B1 combustion classification, rendering them appropriate for insulation systems subjected to sustained weight.

How does long-term compression differ from short-term loading?

Brief compression trials reveal only partial aspects of material response. Duration introduces creep phenomena, often constituting the principal degradation mechanism during actual service life.

What is creep behavior in polystyrene?

Creep describes slow, continuous shape change occurring under an unchanging applied load. Magnitude depends upon density level, surrounding temperature, and mobility in polymer chains. Forces considerably below nominal compressive limits can nonetheless produce detectable deformation across prolonged time spans.

When does creep become a design risk?

Creep assumes particular significance in load-supporting insulation layers, underfloor configurations, and durable packaging elements intended for extended service. Material choices in these situations must accommodate decades-long exposure to steady loading instead of focusing exclusively on maximum instantaneous stress.

How does processing quality affect compression outcomes?

Identical chemical compositions may exhibit markedly divergent compression performance when manufacturing consistency varies.

Why does bead uniformity matter?

Even distribution of bead sizes facilitates balanced force transmission throughout the foam volume, while non-uniform beads establish vulnerable zones where initial collapse occurs under stress. Carefully regulated bead sizing additionally enhances bonding quality during forming operations, thereby enhancing overall structural resilience.

How do curing and aging influence compression stability?

Full curing enables escape of residual expansion gases while allowing internal pressures to reach equilibrium. Inadequate maturation periods strengthen susceptibility to deformation and undermine stable compressive performance under operational conditions.

Where does engineered compression performance create value?

Compression does not invariably signify material failure. A lot of applications deliberately exploit predictable deformation characteristics.

When is controlled compression desirable?

Energy-absorbing packaging systems depend upon reliable compression sequences to dissipate impact forces. Protective solutions for transportation, vibration damping, and shock mitigation all capitalize on gradual, managed cellular collapse rather than rigid opposition to deformation.

How does system-level material design improve outcomes?

In this context, HUASHENG shows distinctive capability. Through deliberate management of polymer structure, bead size consistency, and advanced process modeling, we produce polystyrene variants exhibiting foreseeable compression characteristics across thermal, mechanical, and compliance-related requirements. Such methodology transforms deformation control into an intentional engineering element instead of an unintended flaw.

What should guide compression-related material selection?

Compression response warrants consideration as an integrated system attribute rather than an isolated technical figure.

How do you align compression limits with application demands?

The processes of selection should take into account load magnitude, load duration, environmental temperature, and acceptable deformation limits. Matching specific grade and density values to genuine operational circumstances substantially reduces long-term difficulties.

Why is compressive strength alone not enough?

Compressive strength measurements fail to reflect creep progression, interactions with thermal behavior, or variations arising from production differences. Comprehensive appraisal necessitates evaluation of time-dependent deformation and structural stability under actual service environments.

FAQs

Q1: Does compressed polystyrene permanently lose its insulating ability?

A: Reversible elastic compression produces only modest effects, whereas cellular collapse results in irreversible decline of thermal insulating capacity.

Q2: Can higher-density polystyrene fully prevent compression deformation?

A: Increased density enhances resistance considerably, but cannot eliminate gradual creep under persistent loading conditions.

Q3: Why is compression behavior critical in fire-rated polystyrene systems?

A: Compression frequently disrupts cellular arrangement and uniform additive placement, thereby influencing both mechanical endurance and consistent combustion performance.