Industrial safety helmets are no longer evaluated only by appearance or basic certification labels. Their real performance is determined by internal structure, material behavior, and long-term stability under repetitive stress. For procurement teams, manufacturers, and safety engineers, helmet performance now sits at the intersection of material science, production consistency, and lifecycle reliability.

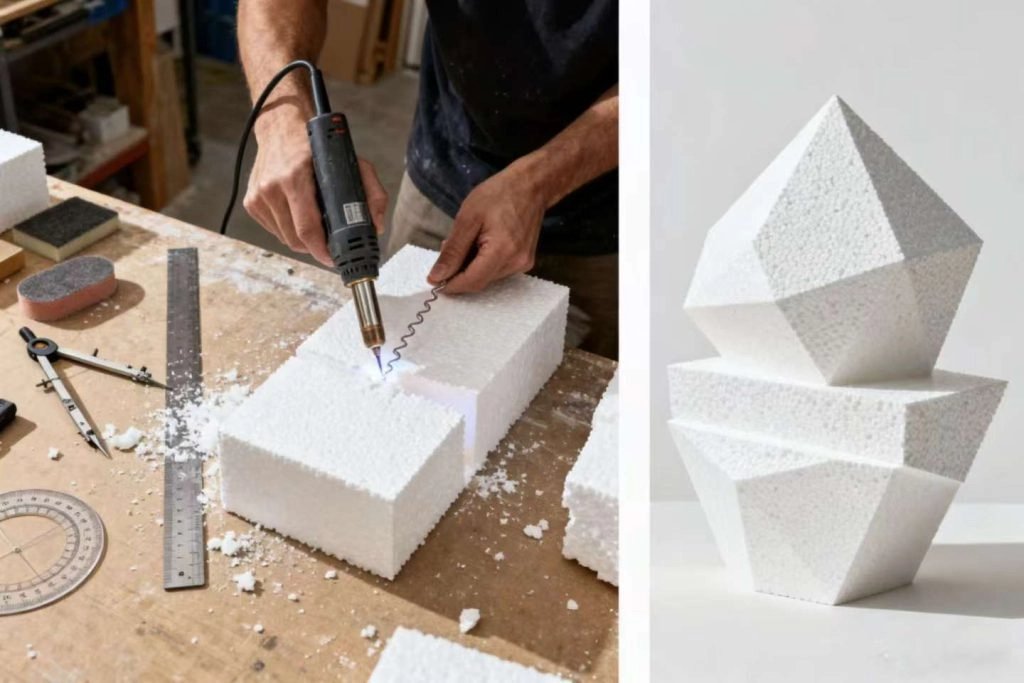

Expanded polystyrene has become an important material in modern helmet systems because it combines impact absorption, lightweight characteristics, processing flexibility, and environmental responsibility. When engineered correctly, EPS does not simply cushion impact but defines how force travels through the shell, how shape stability is maintained over time, and how comfortable the helmet remains during extended use.

Why does helmet structure matter more than appearance in industrial protection?

Visual design plays a role in market acceptance, but structural behavior defines safety outcomes. A helmet’s protective value is created inside the foam, not on the surface.

Impact absorption

Closed-cell EPS structures form a controlled energy-dissipation network. During impact, force is not transmitted directly to the skull but is redistributed across interconnected micro-cells. This behavior mirrors the shock resistance observed in advanced packaging systems, where EPS materials demonstrate high impact resistance and toughness.

Structural integrity

Uniform bead fusion and stable pore bonding ensure that the helmet shell does not collapse unpredictably after repeated impacts. This consistency reduces weak zones, which are often responsible for localized failure during real-world incidents.

A helmet engineered as a structural system rather than a molded shape delivers predictable performance across its full service life.

How does EPS microstructure determine real-world protection performance?

Once the design philosophy is clear, attention is paid to microstructure. The behavior of each bead and pore contributes directly to helmet reliability.

Bead consistency

EPS materials engineered with controlled particle size allow more uniform molding. The sizes of standardized EPS particles typically range from approximately 0.8 to 1.2 mm, with customization possible to achieve refined structural behavior or overall lightweight goals. In helmet production, it enables tighter control of shell density and reduces internal weak bonding areas.

Dimensional stability

Stable pore networks help the helmet retain its original shape after temperature changes, mechanical stress, and aging. Long-term shape retention prevents deformation that could compromise protection or comfort during extended industrial use.

What role does flame-retardant EPS play in industrial safety compliance?

Industrial environments often expose workers to combined risks, including electrical systems, confined spaces, and flammable materials, so helmet materials must therefore offer more than mechanical protection.

Fire behavior

Modern EPS systems can achieve B1-level flame-retardant performance when formulated with appropriate additives. Materials using non-HBCD flame retardants meet EU REACH and ROHS requirements while maintaining fine and uniform cell structures and stable mechanical properties. Such materials demonstrate good flame-retardant behavior, strong adhesion, and dimensional stability.

Regulatory alignment

Helmet manufacturers increasingly face stricter audits tied to global supply chains. Selecting EPS grades aligned with international chemical and environmental standards reduces regulatory friction and supports broader export compliance. Fire safety, therefore, is not an optional feature but part of the structural engineering logic behind advanced helmet systems.

How can material selection balance protection, weight, and wearer fatigue?

Protection loses value if it leads to excessive weight and discomfort. Industrial helmets are worn for long hours, and fatigue becomes a hidden safety risk.

Lightweight engineering

EPS enables density tuning without sacrificing internal bonding strength, allowing manufacturers to create shells that remain structurally robust while minimizing total helmet weight. For users, this translates into lower neck strain and improved endurance across long shifts.

Long-term comfort

Stable cushioning behavior prevents pressure points that emerge when foam deforms unevenly. When bead fusion and pore distribution remain consistent, the helmet maintains its ergonomic fit over time rather than gradually compressing in critical areas. Comfort, in this context, is not cosmetic. It directly influences compliance, concentration, and sustained safety performance.

Where do advanced EPS grades deliver measurable advantages in helmet manufacturing?

The practical value of EPS engineering becomes most visible when specific material grades are applied to different design objectives.

High-performance graphite-grade materials

For helmets that require both mechanical stability and enhanced thermal behavior, G-grade expanded polystyrene materials offer structural advantages through refined bead uniformity and improved performance stability. Graphite-grade systems are widely used in applications demanding stronger dimensional control and higher overall consistency, which aligns well with premium helmet shell requirements.

Ultra-light structural solutions

In designs focused on minimizing weight without sacrificing protective geometry, P-grade expanded polystyrene materials featuring high foaming ratios and stable molding characteristics support the production of lightweight helmet components that still maintain sufficient cohesion and impact dispersion capacity.

Each grade addresses different engineering priorities, allowing helmet manufacturers to tailor protection systems rather than rely on a single generic foam formulation.

Who is HUASHENG, and why are its EPS materials increasingly adopted in safety-focused applications?

One supplier frequently referenced in advanced EPS development is HUASHENG, a high-technology enterprise specializing in expandable polystyrene research, production, and application development. Our company operates intelligent production lines and precision testing systems that target key indicators, such as density uniformity, compressive strength, and thermal stability. Our product types span ordinary, flame-retardant, and graphite-modified EPS systems used across cold-chain logistics, prefabricated construction, seismic-grade packaging sectors, etc.

Beyond manufacturing scale, our company has established a digital twin laboratory combining material gene banks and process simulation platforms, supporting rapid optimization of bead structure and performance. We have also achieved industry-leading advances in nano closed-pore structure technology, increasing compressive strength by 40% through molecular-level structural optimization.

Such capabilities provide helmet manufacturers with access to more predictable, customizable, and performance-focused EPS systems rather than generic foam commodities.

How does sustainable EPS engineering influence long-term procurement decisions?

Procurement decisions increasingly extend beyond unit price and technical performance. Environmental performance and lifecycle efficiency now influence supplier evaluation.

Resource efficiency

Our EPS production systems can reach recycling rates over 95%, combined with advanced compaction technologies that reduce EPS volume to 1/90 of its original size for efficient reuse. Our system supports annual recycling volumes of 300,000 tons while significantly reducing carbon emissions.

Lifecycle value

From a helmet manufacturing perspective, sustainable EPS systems offer practical advantages, including lower material waste during molding, stable processing behavior across production batches, and support for ESG reporting requirements in global supply chains.

Sustainability, therefore, becomes not only an ethical position but also a commercial advantage embedded within the material itself.

What should you evaluate when selecting EPS materials for helmet production?

A structured evaluation approach helps avoid material-related failures later in production or field use.

Mechanical criteria

Compressive strength consistency, bead fusion quality, dimensional stability, and impact resilience should be the primary focus of the assessment. These properties directly determine how the helmet behaves under load rather than how it appears during inspection.

Processing compatibility

Equally important is whether the EPS grade supports efficient molding cycles, consistent demolding, and compatibility with existing production equipment. Our advanced EPS systems can improve molding efficiency by more than 50% while reducing energy consumption by over 20%, which directly impacts manufacturing stability.

Conclusion

The effectiveness of EPS safety helmets depends on how well microstructure, density control, flame behavior, and processing stability are aligned with real-world industrial demands.

When advanced EPS grades are applied thoughtfully, you gain helmets that absorb impact more predictably, remain lightweight under long-term use, resist deformation across lifecycle stress, and support sustainability objectives increasingly demanded by global supply chains.

FAQs

Q: Can EPS-based helmets provide sufficient protection for high-risk industrial environments?

A: Yes. When engineered with stable bead fusion, controlled density, and flame-retardant performance, EPS helmet structures deliver strong impact absorption and predictable mechanical behavior suitable for demanding environments.

Q: Does lighter EPS always mean reduced protection?

A: No. Properly engineered low-density EPS can maintain structural cohesion and energy dispersion through optimized pore structure, allowing weight reduction without sacrificing safety performance.

Q: Why is EPS consistency important in helmet manufacturing?

A: Consistent particle size, stable molding behavior, and uniform internal bonding reduce weak zones, improve production yield, and ensure reliable protective performance across large manufacturing batches.