Foam material selection has shifted from price-driven purchasing to performance-driven engineering decisions. In common applications, foam no longer functions as a simple filler, but works as a structural, thermal, and safety component that directly influences system reliability.

You often face competing options, such as EPS, XPS, PU, EPP, and EPE. Each material claims advantages in insulation, cushioning, or durability. However, the differences in performance do not arise from marketing claims, but from structure, chemistry, processing behavior, and long-term stability.

This guide compares EPS with other foams through practical technical criteria. Instead of focusing on surface features, it helps you evaluate how each material behaves under real operating conditions.

How does EPS differ structurally from other foams?

Cell formation

EPS forms from discrete beads that expand and fuse into a closed-cell network. This bead-based architecture creates defined bonding interfaces between particles. XPS and PU form continuous extrusion structures, while EPP and EPE use different molding mechanisms with higher elasticity.

Density control

EPS density is regulated by expansion ratio and bead size selection, which allows precise control across applications ranging from low-density packaging to structural insulation boards. Other foams often rely on chemical reaction rates or extrusion pressure for density control, which can reduce predictability.

Bonding behavior

The strength of EPS depends on bead fusion quality. Well-fused interfaces produce stable compressive response and dimensional control, while poor fusion leads to brittle fracture zones. This fusion-dependent behavior distinguishes EPS from elastomeric foams such as EPP.

Structural differences define mechanical response, but load behavior adds another layer of selection logic.

Which foam performs better under mechanical load?

Compression

EPS distributes load across bead interfaces. Properly fused grades maintain stable compression with minimal creep. In contrast, EPP offers superior elastic recovery but sacrifices stiffness, and PU provides high initial strength but may degrade under long-term compression.

Impact absorption

EPS absorbs impact through controlled cell collapse and performs well in single-impact protection, such as appliance packaging. EPP excels in repeated impact cycles, such as automotive components.

Long-term stability

EPS exhibits stable geometry when curing and aging are properly controlled. Some chemical foams experience internal gas diffusion over time, leading to the deterioration of thermal performance and size.

Mechanical behavior narrows your choices. Thermal behavior often determines the final decision.

How do thermal properties influence material choice?

Thermal conductivity

Standard EPS exhibits thermal conductivity around 0.038 to 0.040 W/m·K, which can be significantly reduced by modified grade materials. Extruded foams often achieve similar λ-values but require higher processing energy.

Aging effect

Thermal performance in EPS remains relatively stable after curing. PU and XPS may initially test well but lose performance as internal gases diffuse over time.

Thickness efficiency

To reach the same thermal target, EPS panels may require slightly greater thickness than PU. However, EPS compensates with lower density, easier cutting, and simpler system integration.

Thermal performance explains efficiency. Fire behavior defines compliance.

How does fire performance separate EPS from other foams?

Combustion behavior

EPS decomposes through controlled polymer chain breakdown. Flame-retardant EPS materials can change this pathway to limit ignition and suppress flame propagation. PU tends to release more smoke and toxic byproducts, and XPS burns intensely once ignited.

Regulatory grades

Construction projects often require B2 or B1 classification. B2 focuses on flame retardancy, while B1 emphasizes difficult ignition and self-extinguishing behavior.

Materials, such as FS-flame retardant grade materials, are engineered for rapid achievement of B1-level performance, higher strength, short curing cycles, and low smoke density. These characteristics allow EPS systems to meet strict construction fire requirements without sacrificing processing efficiency.

Even with strong material performance, supplier capability plays a decisive role.

Who supplies EPS materials designed for industrial comparison scenarios?

When EPS is treated as an engineering material rather than a commodity, production consistency becomes critical. HUASHENG operates with this design philosophy.

Our company specializes in expandable polystyrene systems across ordinary grades, flame-retardant grades, graphite-modified grades, and environmentally compliant grades. Our product architecture is designed around density uniformity, compressive strength stability, and thermal predictability rather than output volume alone.

Advanced intelligent production lines and precision testing equipment are used to control bead size distribution, expansion behavior, and fusion quality, enabling reliable performance in applications such as building insulation, cold-chain logistics, prefabricated structures, and seismic-resistant packaging.

Beyond conventional EPS, our company has invested heavily in REPS systems, closed-loop manufacturing, and recycled-material engineering. Through digital twin laboratories, material databases, and process simulation platforms, formulation and process parameters are adjusted to meet application-specific targets.

Once supply reliability is secured, the final selection depends on the application context.

When does EPS outperform other foams in real projects?

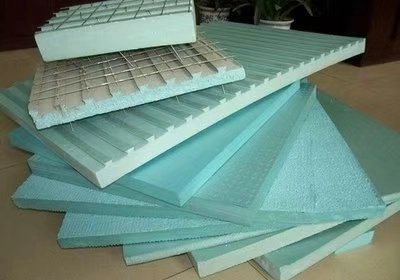

Building insulation

Graphite-modified EPS achieves strong thermal resistance with stable long-term behavior. Compared with XPS, it offers easier cutting, lower embodied energy, and predictable aging.

Cold-chain packaging

EPS maintains temperature stability while remaining lightweight. Compared with PU boxes, EPS systems often offer easier recycling and simpler production scalability.

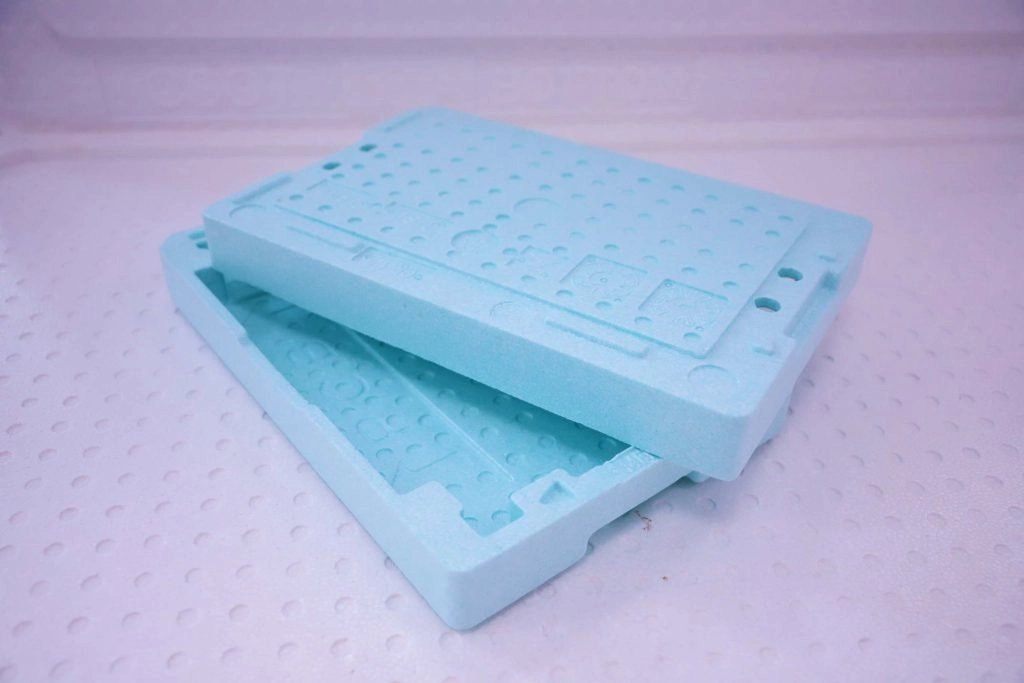

Precision equipment protection

EPS allows accurate molding, dimensional control, and tailored density zones. Compared with EPE, it provides better structural stability for high-value products.

These advantages do not imply universal superiority.

When should you avoid EPS and select other foams?

Ultra-high temperature

EPS softens under sustained high temperatures. PU or specialty foams perform better in heat-intensive environments.

Repeated deformation

If repeated elastic recovery is essential, such as in automotive impact parts, EPP may offer superior lifecycle behavior.

Chemical exposure

Certain solvents and oils can attack polystyrene. Chemical-resistant foams may be more appropriate in aggressive industrial settings.

Selection becomes effective only when you apply a structured framework.

How should you build a practical foam selection framework?

Define load profile

Clarify whether the application involves static load, impact load, or cyclic deformation, which can eliminate unsuitable material classes early.

Define thermal target

Set λ-value requirements and allowable thickness, thus determining whether standard or modified grades are required.

Define fire class

Regulatory compliance often overrides cost considerations. B2 and B1 classifications lead to different material systems.

Define production method

EPS supports high-speed molding and scalable forming, while extrusion foams may require different infrastructure.

In applications focused on certified B2-level building insulation and stable aging behavior, F-flame retardant grade EPS materials are commonly used as a baseline system. These EPS materials exhibit uniform bead size, good fusion, strong dimensional stability, and suitability for building insulation and packaging sectors.

Conclusion

Each material class serves a different structural, thermal, and regulatory function. EPS remains highly competitive because its structure is controllable, its processing is efficient, and its performance can be engineered through formulation rather than chemistry alone.

When you compare materials through load behavior, thermal stability, fire performance, and processing compatibility, EPS often emerges not as the cheapest option, but as the most predictable system.

Material selection then becomes an engineering decision rather than a purchasing shortcut.

FAQs

Q1: Is EPS always cheaper than other foams?

A: Not necessarily. While raw cost is often lower, total system cost depends on molding efficiency, waste rate, compliance treatment, and service life.

Q2: Can flame-retardant EPS replace XPS in exterior insulation systems?

A: In many cases, yes. Properly engineered flame-retardant EPS can achieve comparable thermal and safety performance with lower energy input during production.

Q3: Does EPS lose performance over time?

A: When curing and formulation are controlled, EPS maintains stable compressive and thermal behavior. Most failures originate from poor fusion quality or improper aging, not from the material itself.