For decades, the construction industry’s answer to the building insulation problem was simply to “add more.” More fiberglass, more rock wool, more layers. The result? Walls so thick they looked like castle ramparts, eating up valuable interior square footage and leaving architects frustrated with bulky, awkward designs. It was a trade-off: you could be warm, or you could have space. You rarely got both.

But as we move toward strict Net Zero and Passive House standards, the game has changed. We can no longer afford to build walls that are half a meter thick just to keep the heat in. The industry is buzzing about a material that solves this headache—a darker, smarter evolution of the white foam we all know. It goes by a few names, but it is effectively changing how we approach the building envelope. By integrating graphite into the polymer matrix, this material allows designers to hit aggressive energy targets without turning buildings into bunkers.

The Passive House Challenge: Insulation Without the Bulk

The concept of a Passive House is simple in theory but difficult in practice. The goal is to create a building that uses almost no energy for heating or cooling, relying instead on airtight construction and super-insulation. However, for architects and developers, the math is often brutal. To achieve the required U-values (thermal transmittance) with traditional materials, wall assemblies inevitably grow thicker. This is where the evolution of the polystyrene building sector becomes critical. We need materials that work harder, not just larger.

The Problem with Traditional White EPS

For years, white Expanded Polystyrene (EPS) has been a staple on job sites. It is cheap, lightweight, and does a decent job. But standard white EPS has a limitation: it lets a certain amount of radiant heat pass through its structure. When you are aiming for a standard building code, this is fine. But when you are chasing Net Zero status, “fine” isn’t good enough.

To get a high R-value with standard white foam, you have to stack it deep. In urban areas where land prices are astronomical, losing 10 to 20 centimeters of floor space around the entire perimeter of a building to accommodate thick insulation is a financial nightmare. Developers lose sellable area, and architects lose design freedom. The industry needed a way to increase the thermal resistance of the insulation board without increasing its physical thickness.

Achieving More with Less

This is the specific gap that carbon polystyrene fills. By modifying the bead chemistry, manufacturers have created a product that offers roughly 20% better thermal performance than its white counterpart at the same density. This might sound like a small number, but in construction, it is massive.

As a result, a wall that once needed 300mm of depth can now be thinner. This saves on items like window seals, base supports, and fixing tools. Plus, it supports the clean, up-to-date outlines that modern building styles call for, all while meeting the strict energy needs for Passive House approval. It focuses on smart use of space, along with energy savings.

The Science Behind Carbon Black EPS

Many people see the grey or black color of the insulation boards on a job site and assume it is just a branding choice or a surface coating. It is actually much deeper than that. The darkness runs through every bead of the board. To grasp why black EPS foam works so much better, we must examine how heat flows through a substance. Heat moves via three paths: conduction, convection, and radiation. Regular foam blocks conduction and convection effectively, but it has trouble with radiation.

How Graphite Particles Reflect Heat

The “magic” ingredient here is high-purity graphite or carbon black powder. During the manufacturing of the raw resin—like the specific low thermal conductivity carbon polystyrene suspension FGE produced by HUASHENG—microscopic particles of radiant-reflecting carbon are infused directly into the polystyrene polymer.

Think of these particles as millions of tiny mirrors scattered throughout the foam. When radiant heat creates a path through the foam, it hits these carbon particles and gets reflected and scattered. It creates a tortuous path for heat transfer. Because the heat has a much harder time passing through, the thermal conductivity drops significantly. While standard EPS might sit around a thermal conductivity (lambda value) of 0.038 W/(m·K), high-quality carbon black EPS can drive that number down to 0.032 W/(m·K) or even lower depending on the density.

Density and Thermal Stability

There is a misconception that heavier is always better for insulation, but it is actually about finding the “sweet spot.” EPS high density foam certainly has its place, especially under floor slabs or in roofing applications where it needs to walk on. However, with carbon-enhanced materials, you get superior thermal performance even at medium densities.

The stability of the material is also vital. Unlike some other rigid foams that release gases over time (a process called thermal drift), causing their R-value to drop as the building ages, carbon polystyrene maintains its performance for the life of the building. It relies on trapped air and carbon, neither of which degrades or escapes. This makes it a reliable choice for Passive House projects that need to perform as well in year 20 as they do in year 1.

Material Properties and Application in Construction

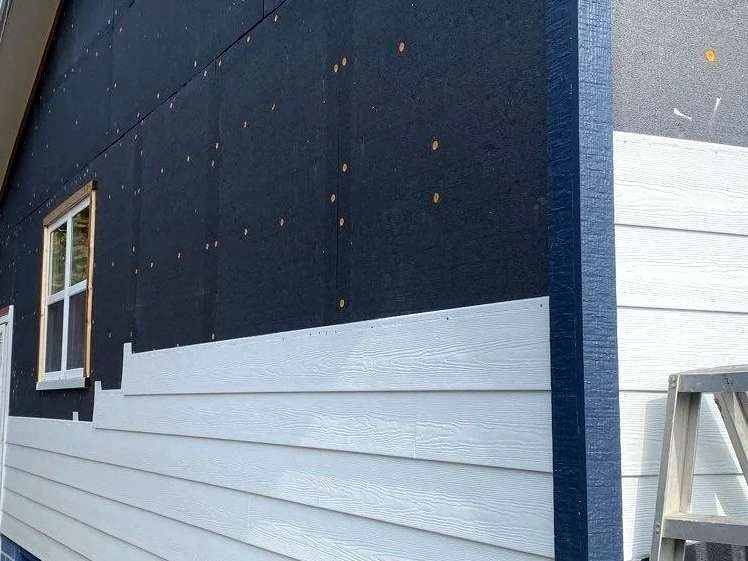

When contractors switch from traditional materials to advanced options like black EPS foam, there is often a learning curve. However, the physical handling of graphite-enhanced EPS is remarkably similar to the white stuff they are used to, which helps with adoption rates. The material brings distinct advantages to the structural integrity and longevity of the building envelope, specifically when dealing with moisture and compression.

Compressive Strength and Durability

In a Net Zero building, the insulation often has to support weight. Whether it is part of an Exterior Insulation and Finishing System (EIFS) holding up layers of stucco, or sitting beneath a concrete foundation slab, the foam cannot collapse. EPS high density foam engineered with carbon additives provides excellent compressive resistance.

It avoids drooping or shifting with time. This matters because settling creates empty spots. Those spots lead to thermal bridges, and such bridges ruin the efficiency of a passive house. A sturdy polystyrene polymer base guarantees the form cut at the start stays the same for decades. Moreover, it keeps its size steady, so it does not shrink much and lowers the chance of cracks in the outer coating.

Moisture Resistance in Envelope Design

Water stands as one of the worst threats to any building. Soaked insulation loses all its value. Low thermal conductivity polystyrene features sealed cells that push away liquid water, yet it lets vapor pass through enough to breathe.

This ability to breathe proves essential. If a wall gets too closed off with non-porous plastic foams, dampness can stay stuck in the space, causing decay and mold growth. Carbon black EPS helps the wall setup dry naturally, avoiding harm to the framework. For a Passive House, which seals out air leaks tightly, a material that handles moisture movement without issues is a must. It fosters a safe indoor space, which holds as much weight as the energy cuts.

Sourcing the Right Material for Net Zero Projects

Not all gray foam is created equal. As the demand for energy-efficient buildings spikes, the market has seen an influx of EPS manufacturers rushing to produce their own versions of graphite EPS. However, the quality of the raw resin—the bead itself—determines the final performance of the board. Variability in carbon distribution, bead fusion, and expansion consistency can lead to products that look the part but fail to perform on the spec sheet.

What to Look for in EPS Manufacturers

When sourcing material for a high-stakes project, consistency is everything. You need a manufacturer who controls the suspension polymerization process tightly. If the carbon does not mix evenly in the polystyrene polymer, hot areas and soft spots appear. Safety comes first, so fine carbon polystyrene includes flame-resistant extras to match tough building standards. It goes beyond R-value; it covers overall safety and function of the base stuff.

The HUASHENG FGE Advantage

This is where raw material suppliers like HUASHENG stand out in the global market. Their specific grade, the low thermal conductivity Carbon Polystyrene Suspension FGE, is engineered for this exact purpose. It isn’t just generic black EPS foam; it is a specialized resin designed for high expansion ratio and uniform cell structure.

HUASHENG’s process ensures that the low thermal conductivity polystyrene beads fuse perfectly during the molding process. For EPS manufacturers buying resin, or architects specifying the final board, knowing the source material allows for better quality control. The FGE grade is specifically formulated to cut thermal conductivity down to that desirable 0.032 W/m.k range. By choosing a supplier that specializes in this chemical engineering, designers ensure their Passive House models translate from computer simulations to real-world performance.

Conclusion

The era of ignoring energy efficiency is over, but the era of sacrificing architectural beauty for thick walls should be over, too. Carbon polystyrene offers the perfect middle ground: extreme performance in a manageable profile. It allows us to build homes that are comfortable, quiet, and incredibly cheap to run, without forcing builders to alter their construction methods drastically.

Whether you are an architect aiming for LEED Platinum or a homeowner wanting to slash heating bills, the quality of your insulation matters. Advanced materials like carbon black EPS, particularly high-grade resins like those from HUASHENG, are the silent heroes of the green building revolution. If you are ready to upgrade your next project and want to explore how these materials can fit into your design, reaching out to us at info@r-eps.com is the first step toward a true Net Zero future.