Have you ever walked past a construction site on a rainy day and seen stacks of white foam boards sitting in a puddle? Or maybe you’ve used a foam cooler at the beach and wondered if the ice melt is actually soaking into the walls. One of the most common questions people ask on Google is simple: “Is EPS waterproof?” Though it appears like a basic “yes or no” response, the actual situation involves more science. In areas like construction and shipping, grasping how expanded polystyrene foam deals with water goes beyond mere interest—it’s a choice worth millions. If you get it wrong, you end up with moldy walls or ruined products. If you get it right, you have an infrastructure that lasts for decades.

Is EPS Foam Actually Waterproof?

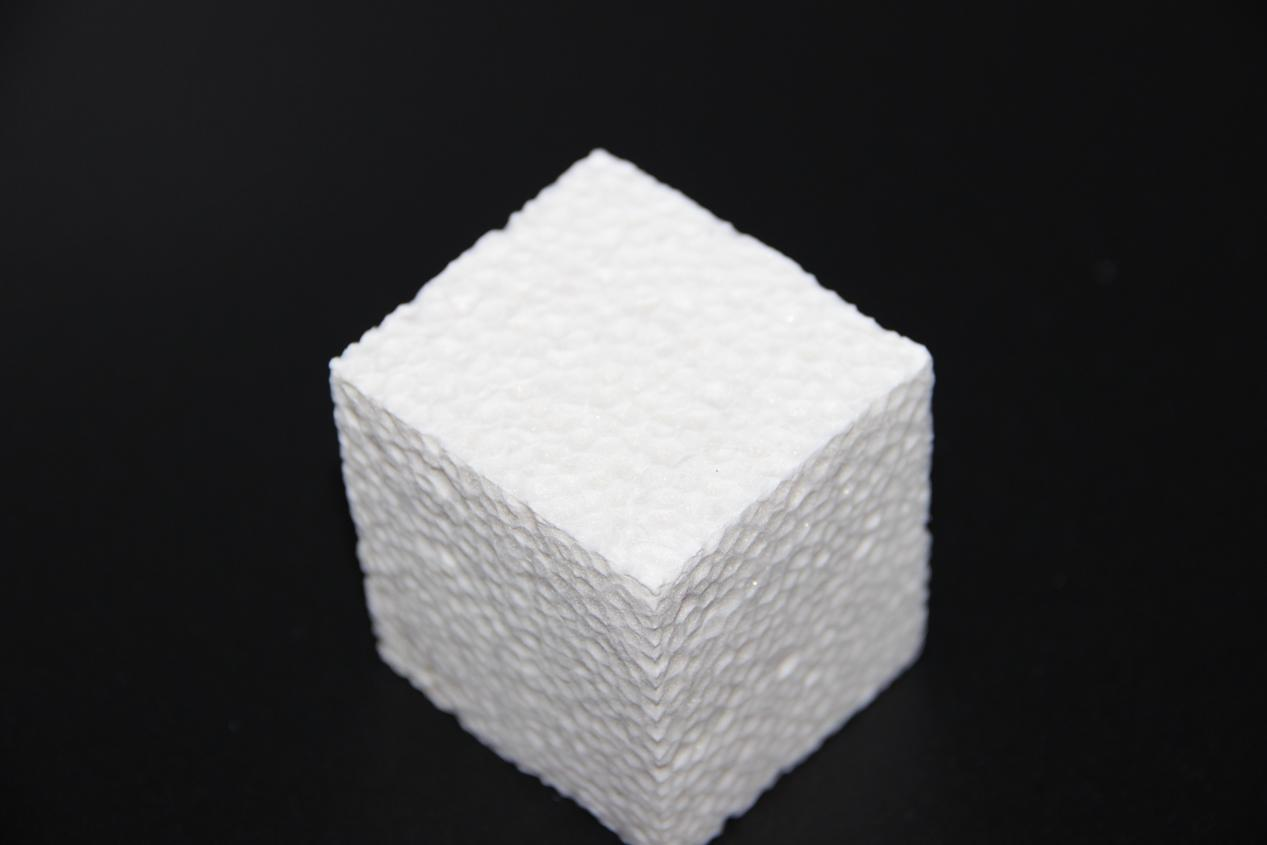

At first glance, a chunk of EPS foam appears as a firm piece. Water tends to form droplets and slide away from the surface, much like on a waterproof jacket. Due to this, plenty of individuals believe it is fully waterproof. Yet, in technical fields, experts use the phrase “moisture resistant.” There exists a slight yet important distinction between an item that repels splashes and one that serves as a complete barrier against vapors over extended times.

The Microscopic Structure of EPS

To grasp why EPS shows such strong moisture resistance, consider its production process. Picture countless small, sealed cells. Each one holds about 98% air and just 2% plastic material. Since these cells remain isolated from each other, liquid water struggles greatly to pass through the substance. It differs from a household sponge with its open paths; instead, it resembles a group of small, airtight balloons stuck together.

This design explains why expanded polystyrene foam works so well. Still, the narrow spaces among those “balloons”—known as interstitial areas—represent spots where moisture might potentially linger. Professional EPS foam manufacturers like HUASHENG focus on how tightly these beads are fused. The better the fusion, the less space there is for water to even think about entering. This is why a high-quality rapid prototyping grade foam feels much denser and smoother than the cheap stuff you might find in a standard shipping box.

Water Absorption Rates

When we talk about science, we need data. In standardized tests, EPS is submerged in water for 24 hours. The results are usually surprising to skeptics. On average, the water absorption by volume for EPS insulation foam is less than 3% to 4%. Even after being buried in damp soil for several years, the “real-world” moisture gain is remarkably low—often staying under 2% by volume if the drainage is decent.

Compare this to other materials. Some fibrous insulation types can act like a wick, pulling water deep into the structure and losing all their thermal value instantly. EPS foam, on the other hand, keeps its shape and its “R-value” (insulation power) even when things get messy. For projects requiring custom EPS foam, these numbers provide the peace of mind that the material won’t turn into a heavy, soggy mess after a few seasons of heavy rain.

Why EPS Moisture Resistance Matters in Construction

In the building industry, moisture is the enemy. It causes wood to rot, metal to rust, and mold to grow. This is why architects are so picky about what they put inside walls or under concrete slabs. If an insulation material holds onto water, it stops being an insulator and starts being a problem.

The Role of EPS in Building Envelopes

Using EPS insulation foam in a “below-grade” application (like under a foundation) is where its moisture properties really shine. Since the foam doesn’t break down in the presence of water and doesn’t provide a food source for bacteria or fungi, it stays functional for the life of the building. It acts as a thermal break that keeps the cold, damp earth from sucking the heat out of your home.

When you look at the long-term performance, EPS moisture resistance ensures that the energy bills stay low for thirty or forty years. Were the foam to take in water like cloth, it would fail to hold air, and the insulating effectiveness would drop sharply. Fortunately, the closed-cell makeup of expanded polystyrene foam keeps the air contained. At the same time, it blocks water entry. Numerous dedicated EPS foam manufacturers now provide various densities. These options strengthen the shield in damp settings even more.

Prevent Mold and Mildew with Breathable Foam

Here is a bit of a “pro-tip”: while EPS is great at keeping liquid water out, it is “vapor permeable.” This sounds like a bad thing, but it’s actually a secret weapon for healthy buildings. It allows tiny amounts of water vapor to pass through slowly. This means that if moisture somehow gets trapped inside a wall, it can eventually dry out instead of sitting there and causing mold.

This balance of blocking liquid water while allowing vapor to move is why custom EPS foam is so popular for modern “breathable” wall systems. It’s a sophisticated way to manage a building’s health. HUASHENG’s common grade EPS is designed with this balance in mind, ensuring that your project stays dry and durable without becoming a “plastic bag” that traps rot.

Custom EPS Foam in Packaging and Logistics

If you’ve ever ordered a high-end laptop or a set of wine glasses, you’ve probably seen EPS packaging in action. In the world of shipping, moisture isn’t just about rain; it’s about humidity changes in shipping containers and condensation during air travel. A box that gets soft when it’s humid is a box that fails to protect its cargo.

Protect Goods with EPS Packaging Solutions

The main reason brands choose EPS packaging over cardboard inserts for heavy or sensitive items is its structural integrity. Cardboard loses almost all its strength when it gets damp. EPS foam, however, remains just as strong in a tropical rainforest as it does in a dry desert. It provides a “cradle” for the product that won’t collapse just because the delivery truck got caught in a storm.

For businesses shipping across oceans, EPS moisture resistance stands as an essential need. Salty breezes and heavy dampness can destroy usual packaging swiftly. Partnering with skilled EPS foam manufacturers allows businesses to create bespoke EPS foam pieces. These match products exactly and maintain a neutral dampness level. Consequently, shipment damage drops, boosting profits significantly.

Thermal Protection for Cold Chain Logistics

Shipping medicine or fresh seafood requires more than just a sturdy box; it requires a temperature-controlled environment. Because EPS foam is such a good insulator and doesn’t absorb the melting ice or condensation, it is the gold standard for “Cold Chain” logistics. It keeps the cold in and the external moisture out.

When sending a medical specimen worldwide, EPS packaging maintains an exact inner temperature. If the substance soaked up dampness, it would create a heat path, spoiling the load. This critical case shows why expanded polystyrene foam quality counts. A steady cell layout ensures the container works reliably each time.

Find Quality Among EPS Foam Manufacturers

Every foam isn’t the same. Purchasing the lowest-cost slabs from an unknown source might reveal weak bead connections, causing greater water intake. For heavy-duty or building purposes, you must understand the material’s makeup and processing fully.

The Importance of Bead Fusion in Quality Foam

A high-quality EPS foam block should be difficult to break apart into individual “beads.” If you can easily rub the foam and it turns into little white balls, the fusion is poor. Poor fusion means there are large “tunnels” between the beads where water can seep in through capillary action. This is the main reason some people think EPS isn’t water-resistant—they’ve simply been using low-quality products.

Reliable EPS foam manufacturers like HUASHENG use advanced steam-molding techniques to ensure that every bead is expanded and fused perfectly. This creates a much more uniform surface that resists water penetration far better than “budget” alternatives. Whether you are using it for EPS insulation foam or a prototype model, that surface tension is your first line of defense against the elements.

Why HUASHENG is Your Best Partner for EPS

When you are looking for a supplier, you want more than just a factory; you want expertise. HUASHENG has devoted years to perfecting Rapid Prototyping Foam and similar special foams. They know the science of expanded polystyrene foam. Plus, they guide you in selecting the proper density for your goals.

Should your task need a particular form or degree of EPS moisture resistance, their experts deliver tailored EPS foam options that align with global rules. From EPS packaging to big construction jobs, they manage large orders without skimping on the “solid bonding” that repels water. Teaming with a reliable maker means no concerns over material breakdown during rough conditions.

Conclusion

So, is EPS waterproof? While it’s technically “moisture resistant,” its performance in wet environments is superior to almost any other common insulation or packaging material. Featuring a water absorption level that holds very low even after prolonged soaking, expanded polystyrene foam offers the most secure option for shielding structures and products from water’s harm. By learning about bead bonding science and selecting suitable EPS foam manufacturers, you can harness the full strength of EPS insulation foam and EPS packaging. If doubts arise about fitting custom EPS foam into your upcoming task, avoid risks. Contact HUASHENG today at info@r-eps.com to get professional advice and high-quality materials that stand the test of time.