Expanded Polystyrene (EPS) foam serves as a light, stiff insulation item made mostly of air. Its closed-cell build gives strong heat resistance. This cuts down needs for heating and cooling in today’s buildings. EPS works well for walls, roofs, and floors. It costs little, lasts long, and brings green advantages since it can be recycled and made without dangerous CFCs. Versions improved with graphite or fire blockers meet top results and safety rules. This makes it an important choice for raising energy savings and outer building strength.

Understanding Expanded Polystyrene Foam Insulation in Modern Construction

Defining EPS Foam and Its Role in Building Envelopes

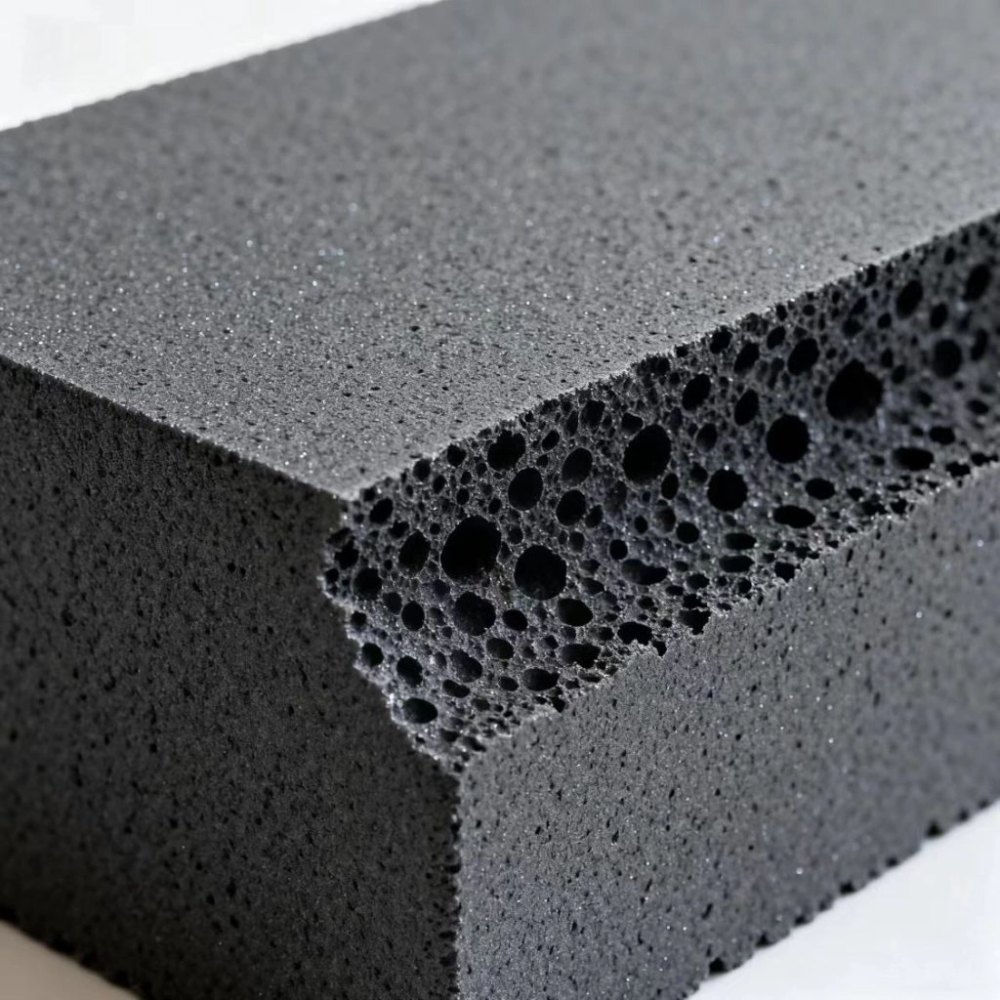

Expanded polystyrene (EPS) stands as a light, hard, closed-cell insulation item formed of 98% air and 2% plastic. This makeup turns it into an effective heat blocker with little material needed. It gains wide notice for keeping steady inside temperatures by lowering heat movement through building covers.

EPS finds wide use in home and business building for heat blocking. It helps cut heating and cooling loads by forming a dependable heat wall. Its placement on outer walls, roofs, and under floors raises energy results. This proves especially true in areas with strict energy rules.

The material holds a main place in better building energy results and cover strength. By cutting unwanted heat passage, EPS insulation aids planners and builders in reaching tough building rules like LEED and Passive House levels.

Applications of EPS in Modern Construction Projects

EPS appears often in walls, roofs, floors, and base systems. It adjusts to many structure demands. Whether placed in sandwich boards or used with exterior insulation finishing systems (EIFS), it backs both heat guarding and design freedom.

The material fits new builds and updates to old structures. For update works, EPS boards install without harming building strength. This ability lets older places meet current energy rules with ease.

EPS works with different building methods including EIFS, sandwich boards, and ready-made concrete. Its simple cutting and fitting promise smooth match with modern outer cover answers.

Manufacturing Process of EPS Foam Insulation

Raw Materials and Expansion Process

EPS comes from polystyrene beads holding pentane as a growing agent. The starting item goes through pre-growth where steam warms the beads, causing pentane to turn to gas and make grown foam beads.

Beads receive pre-growth with steam to create light foam beads. This forms an inside cell setup that holds air—the basic heat blocker in EPS foam.

Beads gain steady state before shaping into blocks or special forms. This makes sure size evenness and readiness for the shaping step.

Molding and Curing Techniques

Grown beads join into blocks or panels through steam shaping. This stage presses beads into firm boards with closed-cell setups that cut heat bridges.

Goods receive curing to steady sizes and improve machine traits. This step proves necessary for keeping power and insulation level during moving and setup.

HUASHENG’s exact control hanging method makes sure even cell setup in goods like FGE graphite EPS. This better way raises heat savings and item sameness across groups.

Performance Advantages of EPS Foam Insulation

Thermal Conductivity and Energy Efficiency

Low heat passage (usually 0.032–0.038 W/m·K) brings outstanding insulation results. HUASHENG’s FGE graphite-better EPS reaches λ values as low as 0.032 W/m·K. This beats usual white EPS.

The material lowers heating and cooling needs. It adds to energy-saving building plans. This cut leads to big running cost savings and better comfort for people through seasons.

Economic Benefits for Long-Term Use

Lower starting cost against many other insulations like XPS or PIR makes EPS appealing for projects watching money. It keeps heat results strong.

Great lasting power promises long work life with little upkeep costs. This fits well for full life cost improvement in business buildings, homes, and factory sites.

Versatility Across Building Components

EPS cuts and shapes easily to fit walls, floors, roofs, or bent surfaces. It handles hard design shapes while holding insulation strength.

Light weight eases moving and setup on site. This cuts work time and tool needs during building stages.

Environmental Considerations and Sustainability Credentials

Made without CFCs or HCFCs; low built energy making process. HUASHENG’s steam growth and recyclable items lower carbon effect at making and end stages.

100% recyclable at end of use; can turn into new EPS goods. HUASHENG recycles 300,000 tons of EPS each year. This saves 1.5 million tons of crude oil and 1.2 million tons of CO₂ releases.

Health and Safety Attributes of EPS Materials

Non-poisonous, non-irritating, resists mold growth and germ spread. This makes sure safe inside air quality and guards against living breakdown over time.

Fire-blocking levels like HUASHENG’s F series raise fire safety following in buildings. They meet world rules like GB8624-2012 for B1-rated items.

Common Applications of HUASHENG EPS Foam Products in Construction Projects

External Wall Insulation Systems (EWIS) and Façade Applications

Gives steady heat wall with little heat bridge danger. This works best in EIFS or air-flow outer cover systems.

Matches with cement covers or outer layers to back look choices while keeping energy results.

Roof Insulation for Flat and Pitched Roof Designs

Brings press strength fit for weight-holding roof uses. HUASHENG’s FSH series beats other levels by more than 20% in press strength.

Water-resistant outside fits turned roof systems. It cuts water entry while holding insulation value under weather.

Floor Slab Insulation Below Concrete or Timber Flooring

High press strength backs structure loads without change. This suits under-slab insulation in light home bases and heavy business floor slabs.

Works as good damp-proof layer with covers. It stops upward water move from ground soils.

Specialty Uses: Garages, Sheds, Cold Rooms & Industrial Buildings

Brings size steady under changing heat states. This makes it perfect for cooled storage like medicine moving boxes or food cold chains.

Fits insulating ready modular builds like sheds, garages, or moving units. Its change ability and steady machine results help.

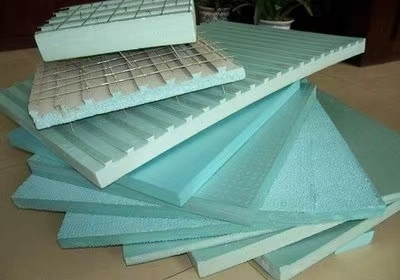

Comparing EPS vs XPS: Technical Differences That Matter

Manufacturing Differences Between EPS and XPS Foams

EPS is made through bead foaming and molding while XPS through melted polystyrene. This difference affects item thickness, cell setup, water resistance, and cost.

Thermal Resistance Performance Comparison

Both give good R-values per inch, but graphite-better EPS (like FGE) beats usual white EPS. The FGE series reaches up to 20% higher insulation savings by bouncing radiant heat in its cell setup. For XPS, it usually has a bit higher R-values but at higher item cost. This makes graphite EPS a better money choice for top building covers.

Moisture Absorption Behavior Under Real Conditions

EPS allows controlled steam passage, reducing the risk of condensation in wall builds. It enables better water handling in breathing structures. In contract, XPS resists water more but can hold water if setup wrong, which may lead to long-term structure worries like rot or mold behind non-pass layers.

Structural Strengths & Compressive Resistance

EPS is available in various thicknesses and suitable for most residential or commercial places where cost-effectiveness is more important than the requirement of strength. XPS has higher compressive strength that makes it more suitable for high-load factory floors, such as loading or unloading areas or cold storage facilities.

Recommended HUASHENG Product Lines for Specific Applications

Flame Retardant Grade – F Series Overview

Flame retardant grade-F is built for raised fire resistance in wall and roof insulation uses. It meets the standard for fire safety in the world and works well for public buildings needing strict rule following.

Graphite Polystyrene (Suspension Method) – FGE Series Overview

Graphite polystyrene FGE made by suspension method uses better hanging joining tech for raised results because it places graphite bits during molecule building for better heat bounce. Compared with the usual other EPS, its ability of insulation increases up to 20% and the kind of EPS is suitable for passive house plans or top building covers.

FAQs

Q: What makes HUASHENG’s graphite-enhanced EPS different from standard white EPS?

A: HUASHENG’s graphite-enhanced EPS (FGE series) incorporates fine graphite particles that reflect radiant heat, significantly improving thermal resistance compared to conventional white EPS—making it ideal for energy-efficient buildings.

Q: Can HUASHENG’s flame retardant grade F be used in high-rise construction?

A: Yes, the flame retardant grade F meets stringent fire safety standards required by many building codes, making it suitable for use in multi-story residential or commercial structures where enhanced fire protection is necessary.

Q: How does HUASHENG ensure consistent quality across its insulation products?

A: HUASHENG utilizes advanced suspension polymerization methods combined with strict quality control protocols during expansion, molding, and curing processes—ensuring uniform cell structure, dimensional stability, and reliable thermal performance across all product lines.