Expanded polystyrene (EPS) has become one of the most common insulation materials in modern construction. Builders choose it for offices, hospitals, apartments, and family homes because it keeps heat inside during winter and outside during summer. The material works well, costs little, stays light, and lasts for many years. No other insulation product matches EPS in all these areas at the same time.

The Role of EPS in Modern Building Insulation

Growing Demand for High-Performance Insulation Materials

Energy rules around the world now ask for much better building insulation. New offices and homes must lose very little heat. Architects and builders need materials that stop heat flow without making the walls too thick or too costly. EPS meets these new rules easily. It gives strong insulation at a fair price and does not add heavy weight to the structure.

EPS as a Versatile and Proven Solution

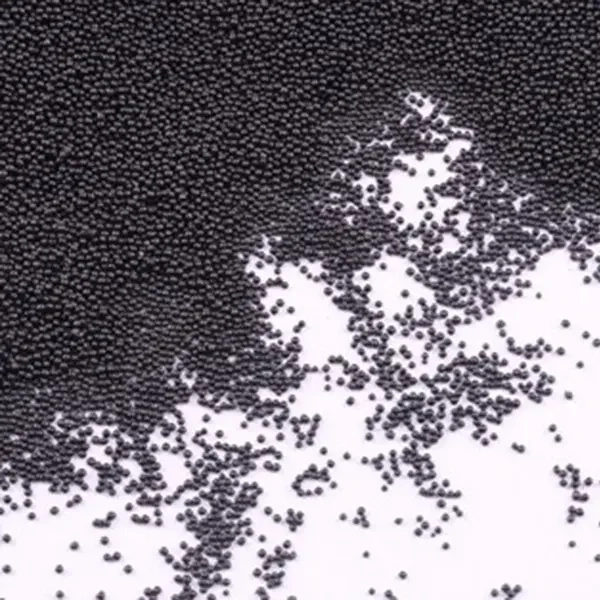

People also call EPS expanded polystyrene. It comes in sheets, blocks, and special shapes. Every form has its own job inside a building. EPS feels light because it is mostly tiny closed air bubbles. These bubbles trap heat and stop it from moving through the wall or roof. The closed cells keep the same insulation power even when the weather changes from cold to hot or dry to wet.

HUASHENG’s Commitment to Advanced EPS Solutions

HUASHENG keeps improving EPS products for today’s buildings. Two strong examples are the Graphite Polystyrene S33 and the Graphite Grade – S panels. S33 introduced the infrared absorbing material–natural flake graphite in the polystyrene polymer material by extrusion process. These newer types block heat even better and also resist fire longer.

Key Characteristics That Make EPS an Excellent Insulation Material

EPS insulation provides excellent thermal resistance, durability, and moisture resistance due to its closed-cell structure. Its lightweight nature simplifies installation and transport, while remaining strong and dimensionally stable. HUASHENG’s enhanced graphite panels offer superior fire safety and energy efficiency for diverse construction applications.

Superior Thermal Insulation Capabilities

Mechanism of Thermal Resistance in EPS

EPS stops heat because millions of small air pockets sit inside the foam beads. Air moves heat very slowly, so the pockets act like tiny blankets. This design keeps the insulation working the same way in summer heat or winter cold.

Performance of HUASHENG’s Graphite Polystyrene (Extrusion Method) – S33

Normal white EPS has a thermal conductivity around 0.039 W/m.K. HUASHENG’s S-33 type drops below 0.033 W/m.K. The thermal conductivity of S-33 is less than 0.033W/M.K, the thermal conductivity of ordinary EPS is 0.039W /M.K, and the thermal insulation performance of S-33 is improved by more than 20%. That means walls need less thickness to reach the same energy-saving level.

Lightweight Nature Enhances Worksite Efficiency

Benefits During Transportation and Installation

EPS weighs very little. Workers can carry big sheets without machines. One or two people can lift and place the boards all day without getting too tired. Trucks also use less fuel because the load stays light.

Structural Advantages Without Compromising Performance

Even though it is light, EPS stays stiff. It does not sink or settle inside walls over the years. Roofs, floors, and foundations stay steady for decades.

Moisture Resistance Through Closed Cell Design

How EPS Limits Water Absorption

The tiny cells inside EPS stay closed. Water cannot travel from one cell to the next. Rain or ground moisture cannot soak through the material the way it does with open-cell foams.

Application Relevance in Wet or Below-grade Areas

Basements and foundation walls often touch damp soil. EPS keeps its insulation power in these wet places when builders add simple drainage and ventilation.

Long-Term Durability Under Real-world Conditions

Resistance to Aging and Deformation Over Time

Years of hot summers and freezing winters do not break EPS. It keeps the same shape and strength from the first day to the last.

HUASHENG’s Graphite Grade – S Panel Durability Profile

These Graphite Grade – S panels reach Class B1 fire rating under Chinese rules. The flame retardant grade reaches Class B1 (GB8624-2012), and the prepared panels and molded products have self-extinguishing fireproof performance. Graphite polystyrene foam is made of imported new materials and innovative processes. Fire stops spreading if it starts.

Design Flexibility Across Diverse Applications

Compatibility With Various Building Components

Workers can cut EPS with a hot wire or simple saw right on site. Factories can also mold it into curves, corners, or special shapes before delivery.

Multi-functional Use Cases Enabled by HUASHENG Products

Exterior Wall Insulation Systems (ETICS)

HUASHENG panels lower heating and cooling bills all year.

Roof Insulation Applications

Light weight means less load on the roof beams while still keeping heat inside.

Floor Slab Insulation

Strong enough to carry heavy floors without crushing.

Foundation Wall Protection

Moisture cannot damage the insulation below ground level.

Why Professionals Choose EPS from HUASHENG

Meeting Regulatory Standards With Confidence

Every HUASHENG product passes strict tests for heat, fire, and safety. F-flame retardant grade has passed the United States Safety Testing Laboratory (UL) certification, document certification number E360952. Architects use these certificates without worry.

Supporting Sustainable Construction Goals

HUASHENG follows green factory rules. The company recycles waste, saves water and power, and cuts air pollution in every step of making EPS.

Value Proposition for Architects and Contractors

Price stays fair, quality stays high, and technical help comes free. HUASHENG gives full service from first drawing to final delivery. We offer comprehensive one-stop services, covering customized solution design, sample production, manufacturing, and logistics delivery.

FAQs

Q: What distinguishes HUASHENG’s Graphite Polystyrene S33 from standard EPS?

A: S-33 introduced the infrared absorbing material — natural flake graphite in the polystyrene polymer material by extrusion process. The graphite particles absorbed and reflected the radiant energy in the foamed beads, which improved the thermal insulation function of the flexible polystyrene core;

Q: Can HUASHENG’s Graphite Grade – S panels be used in fire-sensitive areas?

A: Yes. The panels contain special fire-safe additives and reach B1 fire rating. Flames go out quickly if they start.

Q: How does EPS perform in below-grade applications like basements or foundations?

A: Closed cells block water movement. EPS stays dry and keeps insulating power for decades even when touching wet soil.