Recyclable EPS becomes a real green choice for industry when companies handle it inside a proper reuse circle. The material can be fully recycled and turned into new products many times while keeping the same quality. Modern mechanical recycling methods, especially those developed by HUASHENG, turn old foam into fresh packaging and building items. This process greatly cuts the need for new raw materials and lowers harmful gas release. Its long life and closed-loop possibilities change recyclable EPS from simple waste into a useful resource. When factories add recycled pieces and plan products for easy recycling, EPS meets strict environmental rules. At the same time, it helps businesses save money, raise their green scores, and follow new worldwide laws.

The Evolving Role of EPS in Sustainable Material Strategies

Rethinking EPS Beyond Single-Use Perceptions

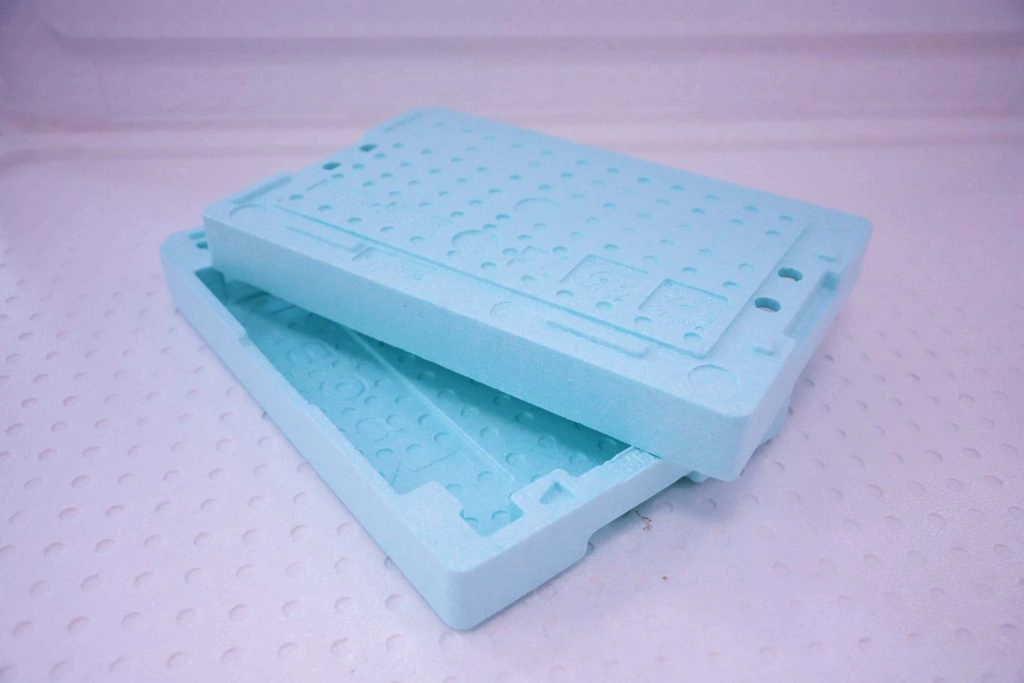

Many people still see Expanded Polystyrene (EPS) only as a one-time plastic. However, this view misses its real strength and ability to be used again. One of the strongest points of EPS lies in its toughness. After it has finished its first job – such as guarding fragile electronics, fresh food, or medical items during shipping – the foam can usually enter a new life through recycling. Its solid structure allows several reuse rounds without losing strength, especially when workers treat it carefully in factory settings.

Companies that once thought of EPS just as cheap cushion material now look at it differently. They begin to notice that recyclable EPS can stay inside a never-ending loop. Old pieces return to the factory and come out as brand-new useful goods. This new way of thinking matters a lot because modern businesses must satisfy both technical needs and environmental goals in areas like cold-chain transport, electronics protection, and medicine delivery.

How Circular Thinking Enhances the Value of EPS?

Applying circular economy ideas to the whole life of EPS changes it from a throw-away item into a lasting resource. When the foam can no longer serve in its original shape, its story does not end there. Recyclable EPS can be processed again and again while keeping its main features. Through reuse and material recovery, factories send far less waste to landfills. At the same time, they release fewer greenhouse gases during the whole lifetime.

This large-scale change matches bigger worldwide targets, such as cutting carbon release and saving natural resources. The strength of recyclable EPS to be reused and recycled fits perfectly with circular economy rules. Especially in packaging and insulation fields, it supports smart long-term plans that will be needed to meet future laws and green demands.

Recyclable EPS: Mechanisms and Industrial Reuse Opportunities

Closed-Loop Recycling Capabilities of EPS

The recycling power of EPS depends on mechanical steps that keep the material strong across many cycles. Used packaging gets collected, washed, and turned back into similar protective items, mainly in closed systems. This ability matters greatly in sectors like electronics, medicine, and fresh food transport, where clean and steady performance is necessary.

HUASHENG processes 300,000 tons of EPS every year. This work saves 1,500,000 tons of oil and stops 1,200,000 tons of carbon dioxide from entering the air. Special machines designed by the company press the foam down to 1/90 of its first size. After that, the dense blocks become new products and raise recycling speed around the world. These modern systems let used foam return to production lines without losing quality, so even strict industrial jobs can use it again.

Industrial Applications Enabled by Recycled EPS

After recycling, the material appears in many different areas. Recycled EPS turns into fresh protective packaging, building insulation boards, plant pots, and home decorations. In construction, it helps create light concrete mixtures and strong insulation panels. The wide range of new uses shows both the flexibility of recycled EPS and its power to replace materials that need more energy and resources.

HUASHENG’s Technological Advancements in Recyclable EPS Solutions

Product Highlight: Extrusion Customized REPS

HUASHENG’s Extrusion Customized REPS shows how careful design can support green goals. The product is built for easy recycling while keeping exact size through many use cycles. It works especially well as shock-proof packing for phones, computers, and cameras. This REPS type can be reused up to five times yet still look good and protect just as well.

The recipe uses 100% recycled EPS particles that have already gone through five lives. Engineers mix the recycled content in a smart way so strength never drops. This makes REPS perfect for special industrial boxes that must be both precise and kind to nature.

Product Highlight: Flame Retardant Grade FHE-N-HBCD

In places where fire safety rules are very strict, HUASHENG offers Flame Retardant Grade FHE-N-HBCD. This grade gives strong fire protection and stays ready for mechanical recycling when the right systems are used. Builders and insulation makers choose it because it follows tough safety laws while still joining the green circle at the end of its life. The product proves that safety and sustainability can work together through clever material science.

Aligning Recyclable EPS with Circular Economy Principles

The Role of HUASHENG in Promoting Circularity Through Design

HUASHENG places circular ideas into every step, from the first drawing to the final collection plan. All materials are shaped to support reuse and smooth recycling. The company works closely with recycling partners so old foam quickly returns to factories. By building a complete chain that covers collection points and production with recycled content, HUASHENG turns circular theory into real daily results.

Benefits of Closed Material Loops for Industry Stakeholders

Closed systems bring clear advantages to everyone involved. Factories need far less new plastic because they mix recycled pieces into fresh goods. This change cuts spending and raises green report scores that banks and customers watch closely. Many customers have seen packaging costs fall by 28% and their ESG points rise by 22 after switching to closed-loop solutions. Such numbers prove that caring for nature can also improve business results.

Environmental Impact Considerations for Recyclable EPS Use

Addressing Misconceptions Around EPS Waste Management

Many people believe EPS always ends up as rubbish because it sometimes carries food or glue. Yet clean white blocks are fully recyclable through grinding and melting. Dirt does create problems, but simple collection rules and better education solve most issues. HUASHENG and similar companies set up special drop-off places only for clean foam, so the material stays pure enough for high-quality recycling.

Comparative Environmental Performance of Recyclable EPS vs Alternatives

Full life-cycle studies often show that recycled EPS beats many other choices when reuse systems exist. It creates 72% less carbon than making brand-new EPS and saves 89% of the energy during recycling steps. Its light weight also lowers fuel use during transport, adding another green benefit. In buildings, the excellent insulation power of EPS cuts heating and cooling needs for decades, bringing both planet and wallet advantages.

Industry Best Practices for Maximizing Recycling Efficiency of EPS

Collection Infrastructure and Sorting Standards

Good recycling starts with clean separation at the beginning. HUASHENG helps create special collection spots only for white, clean EPS waste. Clear rules and public information campaigns keep the material pure so recyclers can work faster and better.

Integration of Post-consumer Content in Manufacturing Processes

HUASHENG mixes used foam back into new production without breaking safety or quality rules. Many modern plants reach over 95% recycling of factory scraps. These habits close the circle and set new world standards for green industry.

Strategic Outlook: The Future of Sustainable Industrial Use of Recyclable EPS

Long-term Value Creation Through Material Innovation

Future progress will keep recyclable EPS important in green industry plans. HUASHENG joins fresh ideas with care for nature – better recycling machines, custom shapes, and worldwide closed-loop networks. New panels with super-insulation aerogel and 3D-printed boxes made only from recycled foam already show the next steps.

Policy Alignment and Market Readiness for Sustainable Materials

As laws around the world push for circular materials, recyclable EPS helps companies stay ahead. It already meets EU Packaging Directive 94/62/EC, beats China’s GB/T 40006-2021 recycled plastic rules, and carries UL 2809 green certification. With stricter laws coming and customers asking for greener products, recyclable EPS stands ready to lead industrial sustainability for many years ahead.

FAQs

Q: Is all Expanded Polystyrene (EPS) recyclable?

A: Clean white rigid EPS is 100% recyclable through mechanical methods such as grinding and re-extrusion. Food or glue can create difficulties, but proper sorting fixes most problems.

Q: How does HUASHENG ensure the sustainability of its recyclable EPS products?

A: HUASHENG builds products like Extrusion Customized REPS for closed-loop systems and adds post-consumer material whenever quality and safety stay perfect.

Q: What are the main industrial benefits of using recyclable flame-retardant grade EPS like FHE-N-HBCD?

A: FHE-N-HBCD brings required fire protection for building projects and stays recyclable with correct handling, giving builders both safety and green responsibility in one material.