Why are many top electric vehicle manufacturers quietly focusing on a foam material commonly used in packaging? Recently, with the global electric vehicle market becoming increasingly competitive, “range anxiety” and “battery safety” have once again made headlines. At this time, a high-tech modified engineered foam—EPS (especially REPS)—has become one of the key materials for engineers to solve the contradiction between lightweighting and safety. This isn’t just about cutting weight; it’s about rethinking how materials can push EV performance further.

EPS foam, made from expanded polystyrene beads, offers a blend of lightness and durability that fits perfectly into modern EV designs. As drivers demand longer ranges without sacrificing comfort or protection, materials like EPS foam insulation are stepping up. In this post, we’ll dive into how EPS foam is changing the game for electric vehicles, from boosting efficiency to enhancing safety features.

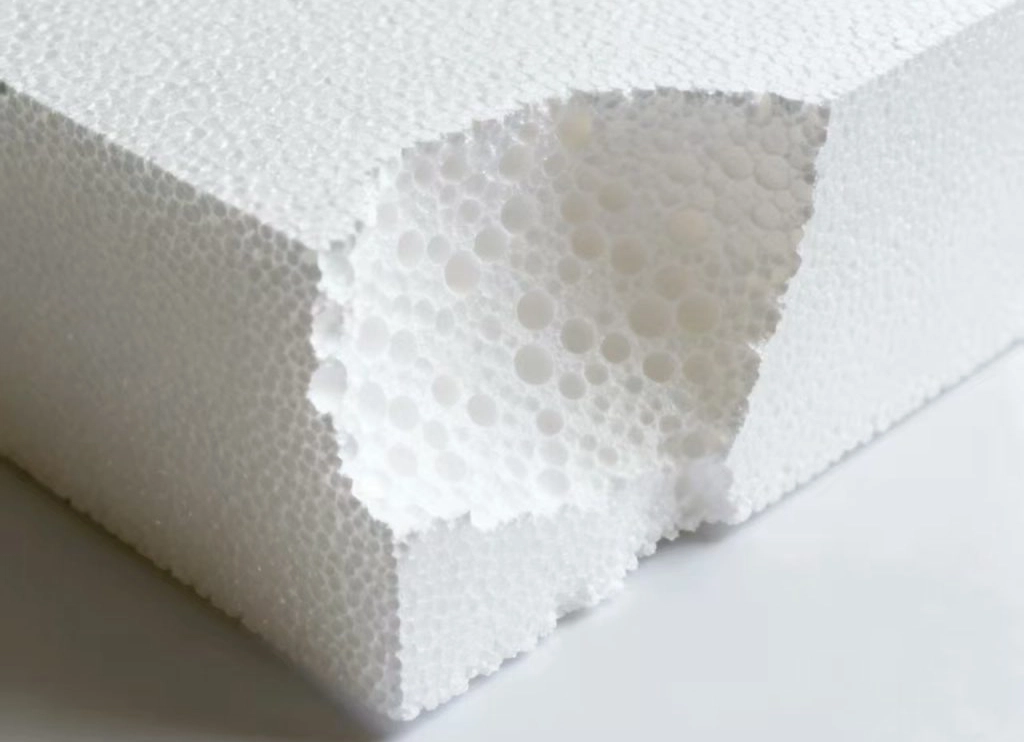

EPS Foam: More Than Just a Lightweight Material

EPS foam has been around for ages in building and wrapping things. But its job in electric vehicles runs much deeper. This stuff, made from EPS polystyrene beads, gives a special mix of traits that suit cars well. As EV builders hunt for ways to cut every bit of heaviness while holding firm shape, EPS foam insulation stands out as a wise pick. It’s not only about lightness. It’s about giving good results where they matter most.

Before exploring its strength aspects, consider how EPS foam adapts to various demands in vehicle engineering. This versatility sets it apart from heavier alternatives, allowing designers to integrate it seamlessly into complex systems.

The Science of Weight Reduction and Strength

At its core, EPS foam starts with tiny eps polystyrene beads that expand under heat to form a cellular structure. This process creates a material that’s up to 98% air, yet it can support significant loads. In EVs, where every kilogram affects battery life, using polystyrene insulation board can reduce overall vehicle weight by 10-20% in targeted areas like battery enclosures. Real-world tests show that EPS foam with densities around 15-30 kg/m³ offers compressive strength up to 100 kPa, making it tough enough for structural roles.

Engineers value this balance. A lighter car means less energy needed to move it, directly tying into range extension. But strength isn’t compromised; the foam’s closed-cell design resists water and maintains integrity over time. For instance, in crash simulations, EPS foam absorbs energy without shattering, unlike some rigid plastics. Suppliers of expanded polystyrene beads refine these beads to meet automotive standards, ensuring consistency in bead size and expansion rates. This precision leads to a uniform polystyrene insulation board that performs reliably in high-stakes environments.

Shifting from pure mechanics, EPS foam’s ability to handle multiple tasks at once makes it even more appealing for EV applications. It doesn’t just sit there; it actively contributes to the vehicle’s overall functionality.

Engineered for Multi-Functionality

EPS foam can give parts many jobs at the same time, like blocking sound (NVH), keeping heat in, or cutting shakes. In an EV, where motors run soft but road buzz can sneak in, EPS foam insulation helps make the inside calm. Checks from car shops point out that adding EPS in door sides drops noise by up to 5-10 dB. That builds a nicer ride.

Past sounds, its heat skills stand out. As EV insulation material, EPS has a low heat flow of about 0.03-0.04 W/m·K, which is great for holding battery warmth. This many-job skill means one stuff can swap out a few. It makes putting together easier and drops costs. For new car seat foam, EPS types give padding that softens shakes. This cuts driver tiredness on long roads. With these base perks in view, let’s shift to how EPS straight-up shapes an EV’s trip length—a big worry for lots of shoppers.

Direct Impact: How EPS Extends Your EV’s Range

Range is everything in the EV world. Drivers want to go farther on a single charge, and EPS foam plays a pivotal role here. By integrating lightweight materials like polystyrene insulation board, manufacturers can shave off weight without losing essential features. This isn’t theoretical; real data from EV models shows measurable gains. To understand this fully, we need to look at the math behind weight and energy use. It’s a straightforward equation, but one that packs a big punch in daily driving.

The Weight-Energy Efficiency Equation

The positive impact on reduced energy consumption and increased driving range comes down to physics. For every 100 kg reduced in vehicle weight, an EV can gain about 5-7% more range, according to data from the U.S. Department of Energy. EPS foam, being so light, contributes significantly. In a typical midsize EV weighing around 2,000 kg, replacing traditional insulators with EPS foam insulation could cut 50-100 kg from the body and interior.

This translates to real miles. Take a car with a 300-mile base range; that weight savings might add 15-20 extra miles per charge. It’s not magic—it’s efficiency. Lower mass means less power drawn from the battery to accelerate or climb hills. Suppliers of expanded polystyrene beads ensure high-quality beads that expand evenly, leading to consistent performance in EV insulation material. HUASHENG stands out as one of the reliable expanded polystyrene beads suppliers, offering products that help achieve these efficiencies.

Moving beyond overall vehicle weight, EPS foam’s role in protecting the heart of the EV—the battery—deserves close attention. Here, it acts as more than insulation; it’s a safeguard.

Beyond the Body: Protect the Battery Pack

As a buffer, heat insulation and support material inside the battery pack, EPS foam, like EV battery foam keeps cells stable. Batteries generate heat during charging and use, and poor management can cut efficiency by 20% or more. EPS foam insulation maintains optimal temperatures, preventing thermal runaway—a risk in high-density packs.

In practice, EV battery foam from polystyrene insulation board surrounds modules, absorbing shocks from rough roads. Tests show it can reduce vibration impact by 30-40%, extending battery life. For instance, in models like those from leading brands, this foam supports packs weighing over 500 kg while adding minimal weight itself. HUASHENG’s REPS line enhances this with recycled content, making it a forward-thinking choice for EV makers.

Safety goes hand in hand with range, as a secure vehicle inspires confidence. Now, let’s examine how EPS serves as a quiet protector in crash scenarios and everyday comfort.

A Silent Guardian EPS in Vehicle Safety Systems

In the fast-paced world of EVs, safety isn’t optional—it’s core. EPS foam steps in as an unsung hero, managing forces that could otherwise cause harm. From absorbing impacts to softening interiors, this material enhances protection without adding bulk.

First, consider the critical moments during a collision. EPS foam’s design allows it to deform predictably, turning potential danger into controlled energy dissipation.

Manage Crash Energy Absorption

How to effectively absorb and disperse impact energy during a collision through controlled crumple deformation is where EPS shines. In front-end crashes, EPS foam in bumpers or structural elements compresses, reducing g-forces on occupants by up to 25%, based on Euro NCAP testing data. This controlled collapse—unlike brittle materials that snap—spreads force over time.

For EVs, where batteries must remain intact, EV battery foam acts as a barrier. It cushions the pack, preventing punctures that could lead to fires. Real crash tests demonstrate that vehicles with EPS reinforcements score higher in side-impact ratings, often achieving 5-star levels.

Enhance Interior Safety and Comfort

Include sun visors that meet head impact standards, energy-absorbing side door panels, and shock-absorbing seat cushions. New car seat foam made from EPS offers resilience, returning to shape after compression and providing support that reduces injury risk in rear-end collisions. Standards like FMVSS 201 require materials to absorb head impacts below 80 g’s, and EPS easily complies.

In door panels, polystyrene insulation board pads absorb side forces, protecting passengers. Comfort-wise, its vibration-damping cuts road buzz, making long drives less tiring. HUASHENG’s lineup includes versatile EPS foam insulation for these applications, ensuring both safety and a premium feel.

As we think about the future, sustainability becomes key. EPS foam, especially advanced versions, aligns with green goals in the EV sector.

The Sustainable Choice Future Proofing with REPS

With EVs leading the charge toward a cleaner planet, materials must follow suit. REPS, an evolved form of EPS, brings recycling into the mix without skimping on performance. This shift supports the entire EV ecosystem, from production to end-of-life. To appreciate this, start with how REPS is made. It turns waste into high-value components, closing the loop in manufacturing.

From Recycled Beads to High Performance

Introducing HUASHENG’s REPS technology, which uses recycled eps polystyrene beads to create superior foam. Up to 50% of the content comes from post-consumer sources, yet it matches or exceeds virgin EPS in strength and insulation. Densities range from 10-40 kg/m³, suitable for EV battery foam and beyond.

This recycling process cuts carbon emissions by 30-40% compared to new production, per life-cycle assessments. HUASHENG, as a top expanded polystyrene beads supplier, invests in tech that refines these beads for automotive-grade quality. Sustainability doesn’t stop at materials; it influences the whole vehicle life cycle, making EVs truly eco-friendly.

Supporting Eco-Friendly EV Lifecycle

REPS aids in reducing manufacturing waste and enables easier recycling at a vehicle’s life. In production, its lightweight nature lowers transport emissions. During use, better insulation means efficient batteries, cutting energy needs by 5-10% over a vehicle’s 150,000-mile lifespan.

At disposal, REPS foam can be granulated and reused, unlike some composites. This supports circular economy goals, appealing to eco-conscious buyers. HUASHENG partners with automakers to customize solutions, ensuring REPS fits seamlessly into sustainable designs.

Conclusion

In the new era of electric vehicles pursuing ultimate efficiency and safety, EPS (especially REPS) foam has evolved from a basic material into a key strategic engineering solution. HUASHENG is committed to providing more advanced and reliable EPS/REPS material systems through continuous research and development, working with automotive industry partners to drive the next leap forward in electric vehicle technology. If you’re involved in EV design or production, exploring these materials could unlock new possibilities. Contact us at info@r-eps.com to discuss how our products, including top-tier eps foam and polystyrene insulation board, can fit your needs. Together, we can build lighter, safer, and greener vehicles for tomorrow.