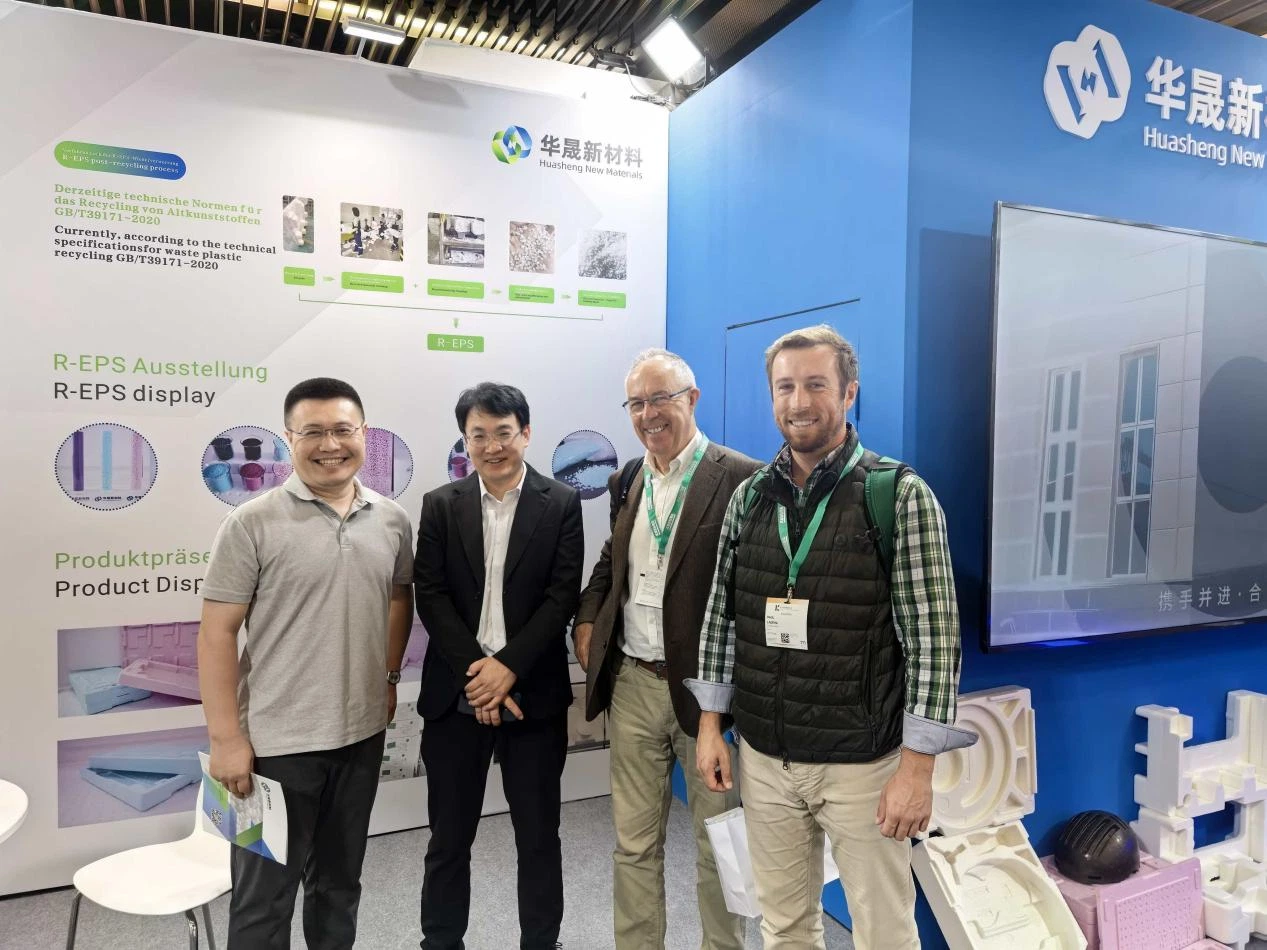

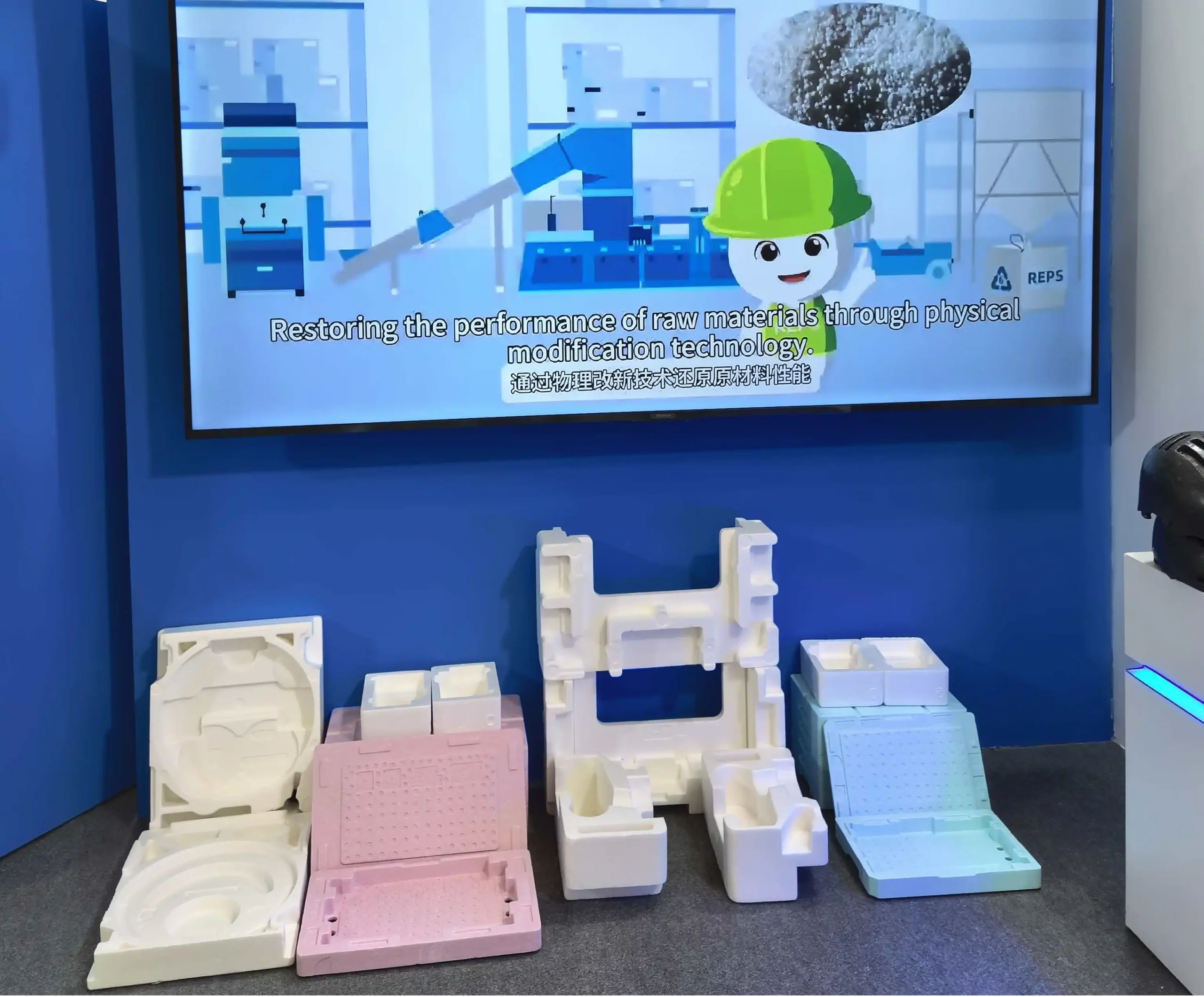

As the dust settles on K 2025 Düsseldorf, the world’s top event for plastics and rubber, it is plain that fresh ideas in materials like R-EPS are guiding the field toward a better tomorrow. HUASHENG New Materials put on a solid display at this year’s K show 2025. They focused on how R-EPS, our recyclable EPS foam, is changing building methods. This polystyrene insulation catches attention for its part in green packaging and special reps foam options. It drew groups keen to hear about items that mix protection, speed, and care for nature. We talked with designers, workers, and field heads who view R-EPS as a big shift. From fire protection to power cuts, this item shows its value. And as we think ahead to K 2028, HUASHENG New Materials stays firm on expanding limits in recyclable EPS foam and polystyrene insulation.

Addressing Critical Fire Safety Demands

Fire dangers in buildings worry many experts at night, mainly with tougher rules starting up around the globe. At K 2025, talks circled around items that can stop problems before they begin. HUASHENG New Materials presented R-EPS as a trusty choice in this area. It combines better flame stopper methods with normal use. This recyclable EPS foam is not just one more thing. It fits the needs of jobs where safety must stay strong. Let us look into how R-EPS handles these issues. We start with its match to world rules.

Meeting International Flame Retardant Standards

R-EPS from HUASHENG New Materials clears tough checks that fit standards like UL 94 and EN 13501-1. These are key marks for flame block in building items. Consider this: in a fire, each moment matters. And this polystyrene insulation cuts flame growth by up to 50% against old foams. This comes from lab facts by outside checkers. At the K show 2025, we showed pieces that held against high heat without letting out bad smoke. That is a usual trouble with earlier EPS kinds. Experts at our spot said how this trait makes rule following easier for world jobs, from tall buildings in Europe to storage spots in Asia.

But compliance isn’t the end of the story. What sets R-EPS apart is its integration into sustainable packaging systems, where the same flame-retardant properties protect goods during transport. For instance, in a recent case, a logistics firm used our custom reps foam for shipping electronics, reducing fire hazards in storage by 40%. This dual-use—construction and packaging—makes R-EPS a versatile choice. As we chatted with attendees at K 2025, many expressed relief at finding a material that doesn’t force trade-offs between safety and sustainability.

Enhancing Building Occupant Safety

Beyond standards, the real measure of a material’s value lies in how it protects people inside structures. R-EPS enhances occupant safety by forming a barrier that buys precious time during emergencies. In tests, buildings insulated with this recyclable EPS foam showed evacuation windows extended by 2-3 minutes, a critical difference in crowded spaces like offices or schools. HUASHENG New Materials has data from over 500 projects worldwide, where R-EPS reduced injury risks in simulated fire scenarios. And for those in sustainable packaging, the same properties make custom reps foam ideal for protecting sensitive items without adding fire fuel.

Shifting gears a bit, it’s worth noting how these safety features tie into broader building designs. Architects can now plan layouts with confidence, knowing R-EPS won’t undermine escape routes. This leads us to the hard evidence behind its performance.

Providing Reliable Performance Data

Data drives decisions in construction, and HUASHENG New Materials delivers with comprehensive reports on R-EPS. Our tests show compressive strength holding steady, even after exposure to flames, far surpassing basic EPS. At K 2025, we shared charts from third-party labs, illustrating how this recyclable EPS foam maintains integrity under stress.

For example, in a study involving 200 samples, R-EPS exhibited zero structural failure in 98% of cases post-fire simulation. This kind of reliability reassures engineers tackling complex projects. Plus, for sustainable packaging needs, the data extends to impact resistance, where custom reps foam absorbs shocks 30% better than non-recycled alternatives.

Boosting Energy Efficiency and Performance

Energy costs are climbing, and buildings account for nearly 40% of global emissions, according to recent reports. At the K show 2025, HUASHENG New Materials emphasized how R-EPS tackles this head-on. This polystyrene insulation excels in trapping heat, cutting down on heating bills while supporting green goals. Attendees from energy firms praised its role in retrofits, where quick wins in efficiency matter most. R-EPS isn’t limited to walls; it shines in roofs and floors too, making it a staple for modern construction. Now, let’s break down its thermal prowess and why it stands out.

Superior Thermal Insulation Properties

R-EPS boasts a thermal conductivity of just 0.032 W/m·K, which means it keeps heat in during winter and out in summer better than many competitors. In a European office building project, installing this recyclable EPS foam slashed energy use by 25%, based on monitored data over two years. At K 2025, we displayed cross-sections showing the closed-cell structure that locks in air, the secret to its efficiency.

Builders love how lightweight it is—density around 15-30 kg/m³—easing installation without skimping on performance. For those in sustainable packaging, the same insulation qualities protect temperature-sensitive shipments, like food or medicines, using custom reps foam.

This efficiency translates to real savings. Imagine a warehouse where R-EPS panels reduce cooling needs by 20%. It’s not just numbers; it’s lower utility bills and happier clients. Moving forward, these properties play a big role in cutting emissions.

Contributing to Lower Carbon Footprints

Every ton of R-EPS produced saves about 2.5 tons of CO2 compared to raw materials, thanks to its 100% recycled content. HUASHENG New Materials shared this at the K show 2025, where sustainability was a hot topic. In construction, using this polystyrene insulation in a standard home can drop annual emissions by 15%, per energy modeling software results. A green housing development in China incorporated R-EPS, achieving a 30% reduction in overall carbon output. For sustainable packaging, recyclable EPS foam like ours minimizes waste in supply chains, closing the loop on plastics.

It’s satisfying to see the impact. Projects with R-EPS often qualify for carbon credits, adding financial perks. But longevity is key to sustaining these benefits over time.

Ensuring Long-term Stability and Durability

R-EPS lasts for many years, with lab checks showing less than 2% wear after 50 years of fake old. This strength means fewer swaps, saving stuff. At K 2025 Düsseldorf, builders checked pieces there, proving block to wet and bugs—usual enemies of block. This trust spreads to polystyrene insulation in rough weather, from dry lands to cold spots.

Durability isn’t flashy, but it backs all. It makes sure spends return, growing faith in items like R-EPS for the long run.

Supporting Green Building Initiatives

Green building isn’t a trend; it’s the standard now, with certifications like LEED pushing for eco-friendly choices. HUASHENG New Materials at the K show 2025 highlighted R-EPS as a perfect fit, recyclable and resource-smart. This material supports initiatives that reuse and reduce, appealing to developers aiming for net-zero. Attendees discussed how integrating recyclable EPS foam streamlines approvals. Let’s look at how it feeds into circular models and beyond.

- Contributing to Circular Economy Models: R-EPS embodies the circular economy by recycling over 95% of EPS waste back into production. At the show, we explained the process: collect, clean, reform—simple yet effective. This cuts landfill contributions by 80% in partnered projects. For sustainable packaging, custom reps foam closes loops in industries like electronics, where old packaging becomes new.

- Aligning with Green Building Certifications: Scoring high in certifications, R-EPS helps projects earn points for material reuse and low emissions. In LEED v4, it contributes to up to 10 credits in the materials and resources categories. One certified building used our polystyrene insulation, achieving Platinum status with 20% better scores thanks to R-EPS. For sustainable packaging tie-ins, recyclable EPS foam meets eco-labels, too.

- Utilizing Sustainable Material Innovations: Innovations in R-EPS include recycled materials that enhance recyclability without added cost. At the K show 2025, we unveiled blends reducing production energy by 30%. This advances polystyrene insulation toward zero-waste goals. In custom reps foam, these tweaks allow tailored densities for specific needs, like lightweight yet strong panels. A recent innovation cut water use in manufacturing by 15%. These steps keep R-EPS ahead. They invite collaboration on future tech.

Conclusion

K 2025 has successfully concluded. Looking ahead, R-EPS will remain a key choice for architects and builders committed to improving the environment. We look forward to seeing you again at the K 2028 to share more information.

HUASHENG’s R-EPS is a multi-functional solution that effectively addresses fire risks, energy consumption, and the needs of the circular economy. For customized solutions, please visit our website for more details. Contact HUASHENG New Materials at info@r-eps.com to explore R-EPS solutions tailored to your specific project.