If you have just received a package containing the limited edition figurine you have been waiting for. But when you open the box, you discover the cushioning material has been crushed, damaging your collectible. Isn’t that frustrating? In industrial packaging and e-commerce, choosing the right material can ensure our products’ safety. Currently, two materials lead the pack: EPE foam and EPS foam. Both are popular choices, but they’re not the same. So, how do we figure out which one works best for us? This guide takes a close look at EPE and EPS foam, breaking down their strengths, uses, and why EPS foam often steals the show—especially in industries like fish packaging in Europe. Let’s dive in and sort out these two packaging options to help you choose wisely.

What Are EPE Foam and EPS Foam?

Getting the simple facts on EPE foam and EPS foam is the first move to choosing right. Each starts from different raw materials and does special jobs in packing and more. Let’s split up what makes each one work.

EPE: The Epitome of Softness & Flexibility

EPE foam, or expanded polyethylene foam, begins with raw stuff—polyethylene pellets. After it gets hot and puffed up, it turns into a gentle, shut-cell build. The end item is a bendy and light foam that can wrap around weird forms easily.

EPE foam gives good padding traits. Its stretch lets it take in bumps, so it fits well for breakable things like gadgets or cups. Makers often pick it for stuffing in boxes or covering parts. In Europe, EPE foam shows up in some food wraps, but it gets used less for quick-spoil foods like fish because of its okay warmth-keeping skills. Its power to pull and bounce back works for spots that need a tight hold without hard backing.

EPS: The Paradigm of Rigidity & Structure

EPS foam, short for expanded polystyrene foam, starts with tiny polystyrene beads made from raw stuff—styrene monomers. These beads grow big when heated with steam. Then they form a hard, shut-cell foam. Unlike EPE, EPS foam stays stiff. It gives shape help. In Europe, folks who send fish count on EPS foam boxes to hold seafood cool on long trips. This is thanks to better warmth-keeping.

At HUASHENG, we make expanded polystyrene beads that change into items like EPS foam panels and custom EPS foam shapes. The hardness makes EPS foam a main pick for building warmth-keeping and tough packing.

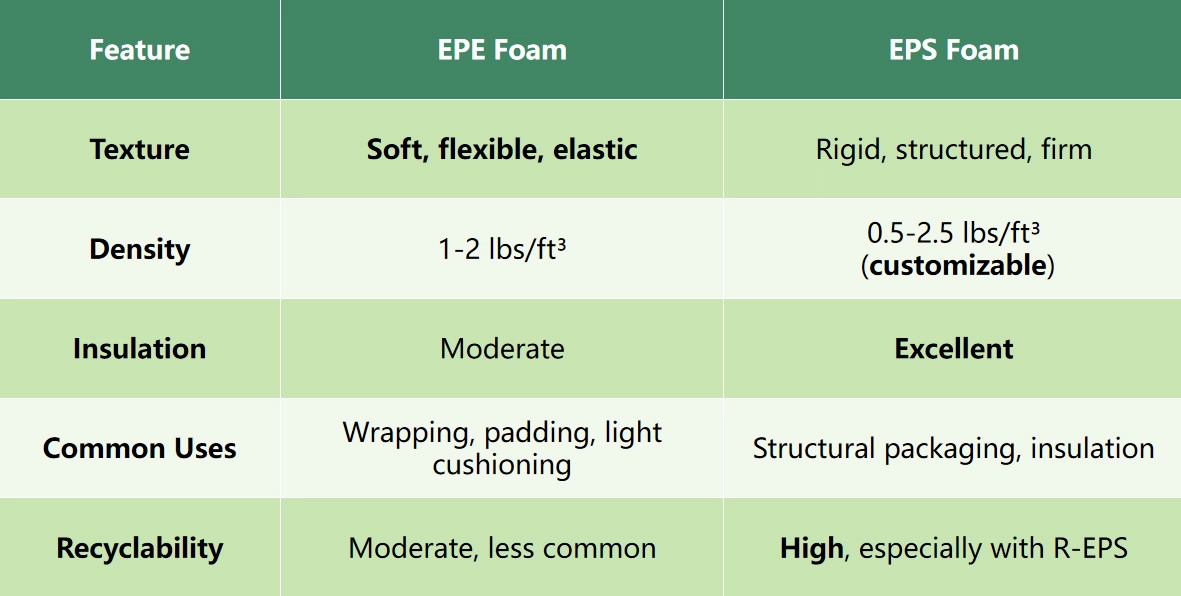

To get the gaps, think about how EPE and EPS foam touch and act. EPE feels soft and easy to fold, like a sponge you can twist. EPS stays firm. It keeps its form under pressure. Here’s a quick comparison:

EPE and EPS foam each have strengths, but their differences in protection, cost, and durability can sway your decision. Let’s compare them across key factors to see where each excels and why EPS foam often stands out.

Comprehensive Comparison of EPS & EPE

Picking between EPE foam and EPS foam depends on what you care about most. That could be safety, price, or harm to nature. Both stuffs pad well, but they do different in real spots. HUASHENG knows a lot about EPS foam sellers and made-to-fit answers. This lets us see clearly what each one offers. Let’s break down the key differences.

Shock Absorption & Compression Resistance

PE foam does great at taking in shocks. Its bendy nature lets it grab hits. So it works best for light, easy-break things like phone covers or tiny pots. But under big or long push, EPE can squash down. And then it loses its padding strength.

EPS foam does better at fighting squash. It’s hard to build spreads force out even. This guards bigger or heavier stuff. HUASHENG’s Special Grade–G EPS uses expanded polystyrene beads made for thickness. It makes sure strong safety without too much heaviness. This fits EPS foam well for shape packing where things must stay put.

Weight & Cost: The Impact on Operational Efficiency

Weight matters in shipping. EPE foam is light, typically 1-2 pounds per cubic foot, reducing transport costs for small packages. Its upfront cost is low, making it attractive for budget-conscious businesses. But it may require thicker layers for heavy items, adding bulk.

EPS foam, while slightly denser, offers customizable density through expanded polystyrene beads. For example, HUASHENG’s custom EPS foam solutions perfectly balance weight and strength. Our EPS foam panels for construction are lightweight yet durable, cutting energy costs in buildings. In packaging, the efficiency of EPS foam is particularly evident in high-volume transport, such as cold chain transport in Europe, where compact and sturdy crates can save space and fuel.

In terms of cost, EPS foam may initially be more expensive due to the molding process. However, its durability and recyclability (such as HUASHENG’s R-EPS, which is made from 100% recycled material) can reduce long-term costs. Businesses can save on replacement and waste disposal expenses.

Water Resistance & Durability

Both foams resist water, but EPS foam edges out slightly. EPE foam repels moisture well, suitable for humid environments like plant packaging. Yet, its softer structure can wear down under repeated stress.

EPS foam’s rigid build handles water and wear better. In the field of seafood transportation, EPS foam boxes can remain intact even in humid and icy environments, ensuring the freshness of seafood. HUASHENG’s EPS foam products, including custom EPS foam, resist degradation, ensuring reliable performance over time. And our recycling process turns waste into new expanded polystyrene foam, supporting sustainability.

The Best Usage Scenarios for EPE & EPS

Knowing when to use EPE or EPS foam depends on your product and logistics. Each material suits distinct needs, from flexible wrapping to rigid molds. Here’s when each foam works best.

When to Choose EPE

EPE foam is your pick for items needing a soft, adaptable cushion. Its flexibility suits:

- Electronics: Wrapping circuit boards or small devices where tight fits matter.

- Fragile Crafts: Padding glass ornaments or pottery during shipping.

- Lightweight Packaging: Filling gaps in boxes for small, delicate products.

EPE foam’s elasticity makes it great for one-off shipments or low-weight items. However, for heavy loads or long-term storage, it may compress, reducing protection.

When to Choose EPS

EPS foam shines where structure and insulation are key. HUASHENG’s custom EPS foam offers tailored solutions. Choose EPS foam for:

- Heavy-Duty Packaging: Protecting appliances or machinery during transit.

- Cold Chain Transportation: EPS foam boxes keep seafood fresh with excellent insulation, outperforming EPE foam in cold chains.

- Construction: EPS foam panels insulate buildings, cutting energy costs.

- Custom Molds: HUASHENG’s expanded polystyrene beads can be shaped for precise fits, ideal for electronics trays or medical equipment packaging.

Our Special Grade–G, with customizable density (1.4-2.3 mm beads, 90-110 expansion ratio), ensures lightweight yet strong protection. It’s perfect for filling voids or crafting custom foam packaging for delicate items like OLED panels or laptops.

Conclusion

EPE foam and EPS foam both protect, but they serve different needs. EPE foam’s softness and flexibility make it great for lightweight, delicate items needing a snug wrap. Meanwhile, EPS foam excels in structural protection and cost control. Its strong structure, customizable density and excellent thermal insulation properties make it a top choice in industries such as construction and seafood export and food transportation.

At HUASHENG, we craft EPS foam that’s not just high-quality but also eco-friendly, with recycled options like R-EPS. For businesses seeking efficient, lightweight, and highly customizable packaging solutions, HUASHENG can easily meet your needs. Contact us today at info@r-eps.com to explore our EPS foam solutions and find the perfect fit for your products.