Expanded Polystyrene (EPS) rigid insulation is a go-to material in today’s construction world. It’s tough, budget-friendly, and keeps buildings cozy by cutting down on heat loss. With stricter energy rules and a big push for greener buildings, EPS shines for its knack at beefing up walls, slashing energy bills, and holding up against all sorts of weather. This article digs into what makes EPS tick—its makeup, performance, and how it’s used—showing why architects, builders, and engineers keep picking it for top-notch, eco-friendly projects.

Introduction to EPS Rigid Insulation

Building a solid, energy-saving wall system? Rigid insulation is key. Expanded Polystyrene (EPS) stands out big time for being versatile, wallet-friendly, and great at keeping heat where it belongs. Whether you’re putting up a new place or fixing up old walls, EPS works like a charm across all sorts of climates and setups.

Composition and Manufacturing Process

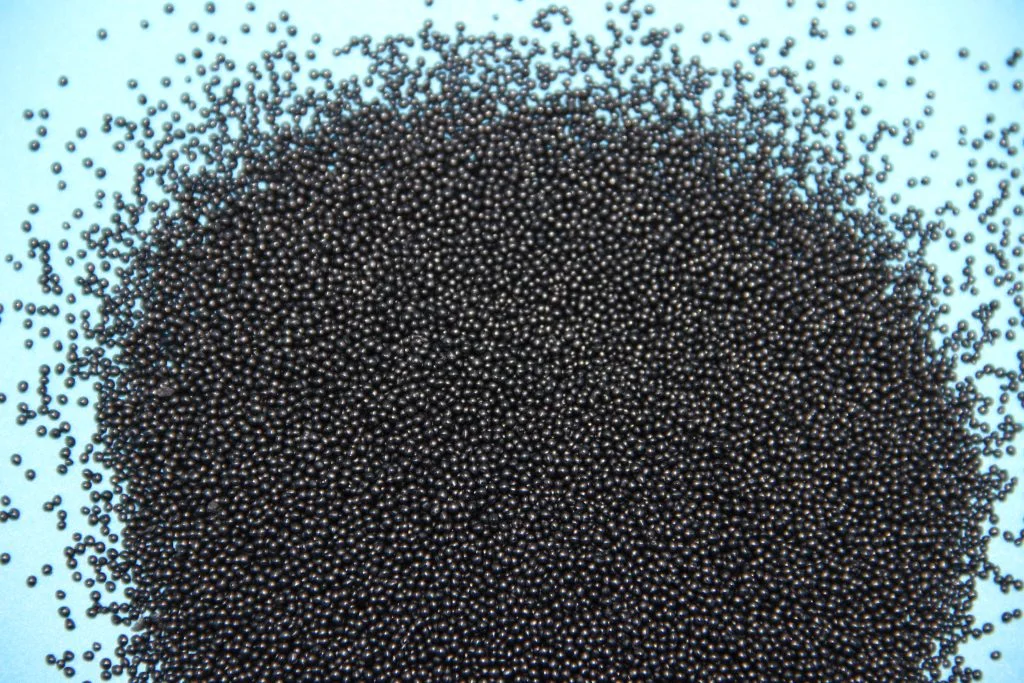

EPS rigid insulation comes from puffing up polystyrene beads with steam in a molding process. Those beads get squished together into solid blocks or panels of closed-cell foam. It’s sturdy and great at trapping heat. You can tweak the density and size during production, so it fits all kinds of projects, from homes to big commercial buildings.

Thermal Performance Characteristics

EPS stands out because its thermal resistance per inch stays pretty steady. For regular white EPS, you’re usually looking at an R-value in the ballpark of 3.6 to 4.2 per inch. Not bad. But some newer mixes push things further—graphite-added boards, for example, can climb past R-5 an inch. This enhanced performance makes products such as Low Thermal Conductivity Carbon Polystyrene (Suspension) – FGE ideal for projects requiring higher energy efficiency with thinner wall profiles.

omparison with Other Rigid Insulation Materials

When stacked up against XPS or polyisocyanurate boards, EPS hits a sweet spot with its low cost and solid performance. Sure, XPS might start with a bit better R-value, but EPS keeps its heat-trapping power steady over time, aging better. Plus, it’s kinder to the planet during production and lets vapor pass through more easily, which helps keep moisture in check within walls.

Benefits of EPS Rigid Insulation in Exterior Wall Systems

EPS rigid insulation offers multiple advantages that directly enhance the building envelope’s energy efficiency and durability.

Energy Efficiency and Thermal Resistance

These products are top-notch at keeping heat where it belongs. They cut down on energy use in buildings big time. By blocking heat from sneaking through outer walls, EPS slashes HVAC demands all year round. It’s a real game-changer in crazy hot or cold climates.

Moisture Management and Water Resistance

EPS’s closed-cell structure resists water absorption while allowing vapor diffusion, helping prevent condensation within wall assemblies. This balance is critical in maintaining indoor air quality and preventing mold growth over time.

Structural Integrity and Long-Term Durability

EPS panels retain their shape without sagging or compressing under load. Their dimensional stability ensures consistent performance over decades with minimal maintenance requirements—making them well-suited for both load-bearing and non-load-bearing exterior walls.

Application Methods for EPS Rigid Insulation on Exterior Walls

The effectiveness of EPS depends not only on the material itself but also on how it’s installed within the wall system.

Installation Techniques for Different Wall Assemblies

Whether you’re working with wood framing, steel studs, or masonry substrates, EPS can be applied using different attachment methods tailored to your project’s needs.

Adhered vs. Mechanically Fastened Systems

Adhered systems use compatible adhesives to bond EPS panels directly to substrates—ideal for smooth surfaces where minimizing thermal bridging is crucial. Mechanically fastened systems involve anchoring with washers and screws through sheathing layers; this method provides additional security against wind uplift in high-exposure zones.

Integration with Weather-Resistive Barriers

Proper sequencing is essential: WRBs should either be behind or integrated into the insulation layer, depending on code requirements. Taping seams between panels or using integrated WRB-EPS hybrid products helps create a continuous barrier against air and moisture infiltration.

Compatibility with Cladding Systems

EPS plays nice with all sorts of cladding, like stucco (EIFS), metal panels, fiber cement boards, brick veneers, and rainscreens. It’s super light, so it doesn’t weigh down the structure. Plus, it gives you plenty of wiggle room for cool design looks without skimping on heat-blocking power.

Regulatory Compliance and Industry Standards

To ensure safe application across building types and jurisdictions, EPS must meet stringent regulatory benchmarks.

Fire Performance Ratings and Code Requirements

In many regions, fire-rated assemblies require flame-retardant grades such as B1-rated EPS materials that meet EN13501-1 Class E or ASTM E84 standards when combined with appropriate protective layers like gypsum board or mineral wool facades. Solution: B1 flame-retardant EPS particles (density 22kg/m³)

Environmental Certifications and Sustainability Metrics

Not only do buildings become more energy-efficient, but the overall reduction in energy use also significantly contributes to the mitigation of greenhouse gas emissions. Many EPS products contribute toward LEED credits due to their recyclability, low VOC emissions during installation, and low embodied carbon compared to other rigid insulations.

HUASHENG EPS Rigid Insulation Solutions

Looking for a maker that blends fresh ideas with a solid track record in exterior wall insulation? HUASHENG is a good place to stop. They’ve been at it for decades, building know-how in foam tech and putting steady money into R&D. The result? Systems that don’t just tick the box but actually raise the bar for the whole field.

What really drives HUASHENG forward is its stubborn focus on new tech and smarter design. The lineup is wide—everything from the classic white panels most folks know, to graphite-boosted boards built to handle tough weather.

Overview of HUASHENG’s Product Line for Exterior Walls

These are ideal for general applications, offering reliable insulation at an economical price point—suitable where moderate R-values suffice without sacrificing quality or durability. For projects targeting high-performance envelopes or net-zero goals, GEPS panels such as Low Thermal Conductivity Carbon Polystyrene (Suspension) – FGE offer superior R-values per inch thanks to infrared-reflecting carbon particles embedded into the matrix structure.

Key Technical Specifications and Performance Data

You’ll find options ranging from densities of 13–30 kg/m³ depending on structural needs. Fire-retardant additives are incorporated during bead expansion rather than surface coating—ensuring consistent protection throughout each panel’s volume.

Selecting the Right HUASHENG EPS Product

Picking the right solution isn’t a one-size-fits-all deal. You’ve got to look at your project details—things like the climate zone (per IECC), how the wall is put together (continuous or cavity), and what type of building it is, residential or commercial. Fire rating matters too. And of course, the budget always comes into play.

Factors to Consider

Colder zones benefit most from graphite-enhanced variants due to higher heating demands; conversely, warm-humid zones prioritize vapor permeability over maximum R-value per inch.

Recommended HUASHENG Products

Use standard white panels for mid-rise multifamily housing where cost-efficiency matters most; opt for GEPS like FGE in passive house designs or public buildings seeking LEED Gold certification, which one project achieved thanks partly to these materials •The overall energy saving rate of the building increased by 14%

Enhancing Building Envelope Performance

Continuous insulation strategies are now mandated by many codes—and rightly so—as they eliminate thermal bridging at framing junctions that degrade real-world performance versus modeled expectations.

EPS excels here because it’s easy to cut around penetrations yet maintains joint integrity when sealed properly—enabling true continuity across complex façades without adding excessive bulk or weight. When input into simulation software like EnergyPlus or IESVE using accurate material specs from HUASHENG, you can demonstrate compliance with ASHRAE 90.1 targets while optimizing envelope-to-HVAC tradeoffs early in design stages.

Long-Term Value of Using HUASHENG EPS

Beyond upfront costs lies long-term value—a factor often overlooked during specification but crucial over a building’s lifecycle.

The durability and stable thermal resistance mean fewer repairs or replacements over time—and greater operational savings year after year as utility bills decline due to better envelope control. EPS panels are easy to patch during façade renovations; they’re also compatible with retrofit claddings like EIFS overlays—extending building life without full tear-downs or costly re-insulations.

FAQ

Q: Can I use standard white EPS in humid climates?

A: Yes—but ensure proper integration with vapor-permeable WRBs since standard white EPS has limited vapor transmission; graphite-enhanced versions may offer better control when paired correctly.

Q: How does graphite-enhanced EPS differ from traditional types?

A: Graphite particles reflect radiant heat within the foam matrix—enhancing its thermal resistance significantly compared to standard white beads at similar thicknesses.

Q: Are these products recyclable after use?

A: The use of HUASHENG ’s EPS foam packaging reduces the need for excessive and often non-environmentally friendly materials, making them recyclable under PS category 6 protocols—supporting both environmental goals and circular economy initiatives.